Machining device for filtering part arranged in sewage purifier

A technology for processing equipment and purifiers, applied in metal processing and other directions, can solve the problems of low alignment accuracy, low degree of automation, and affecting the production efficiency of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

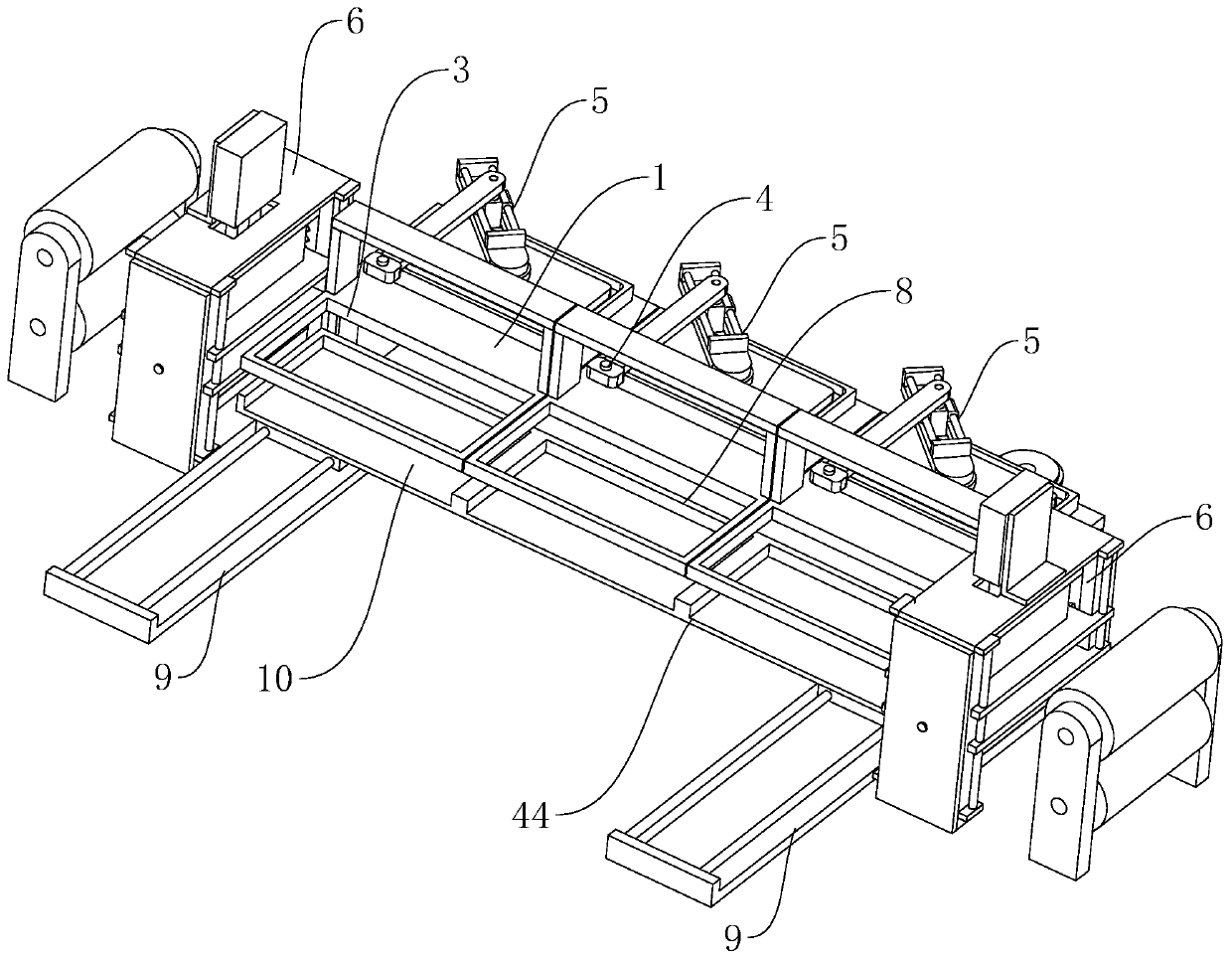

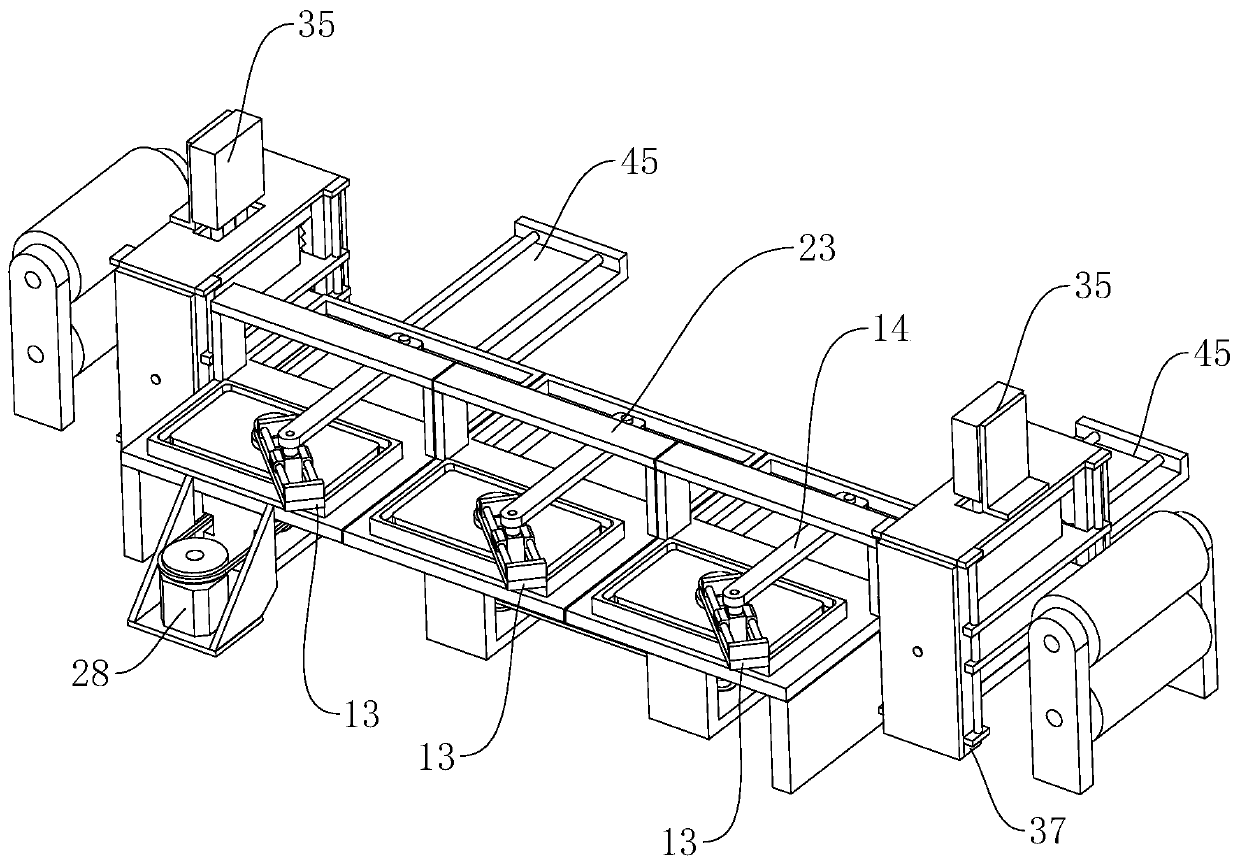

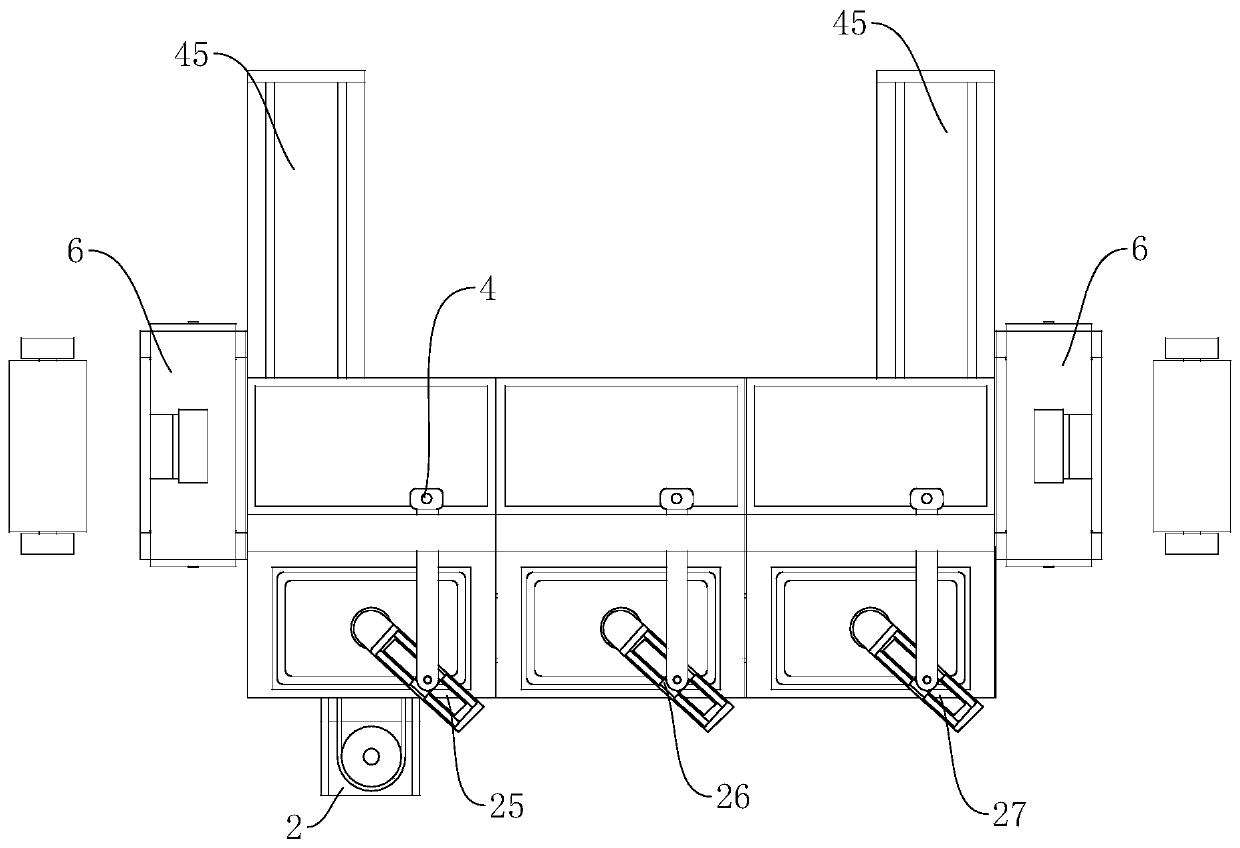

[0024] refer to Figure 1 to Figure 8The processing equipment shown in a sewage purifier with filter elements includes a processing table 1, a laser cutting mechanism, a bidirectional positioning mechanism and a feeding mechanism, and the laser cutting mechanism includes several laser cutting components and synchronous components 2 , a number of laser cutting assemblies are arranged side by side on the table top of the processing table 1, and the processing table 1 is provided with a material transfer incision 3 corresponding to each laser cutting assembly one by one. The multiple laser cutting assemblies have the same structure. In this embodiment Among them, there are three laser cutting assemblies, each laser cutting assembly includes a laser cutting head 4 and a laser driving assembly 5 capable of driving the laser cutting head 4 to move in a rectangular manner, and the laser driving assembly 5 is located on the table top of the processing table 1 , all the laser cutting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com