Aero-engine direct thrust control method based on nonlinear model prediction control

A nonlinear model and aero-engine technology, applied in the direction of engine control, engine function, engine components, etc., can solve problems such as the decline in thrust control accuracy, and achieve the effect of improving control accuracy and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Aiming at the deficiencies of the prior art, the idea of the present invention is to use the thrust as the direct control target and use the nonlinear model predictive control method for control, thereby improving the control accuracy and response speed of the aeroengine control system.

[0025] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

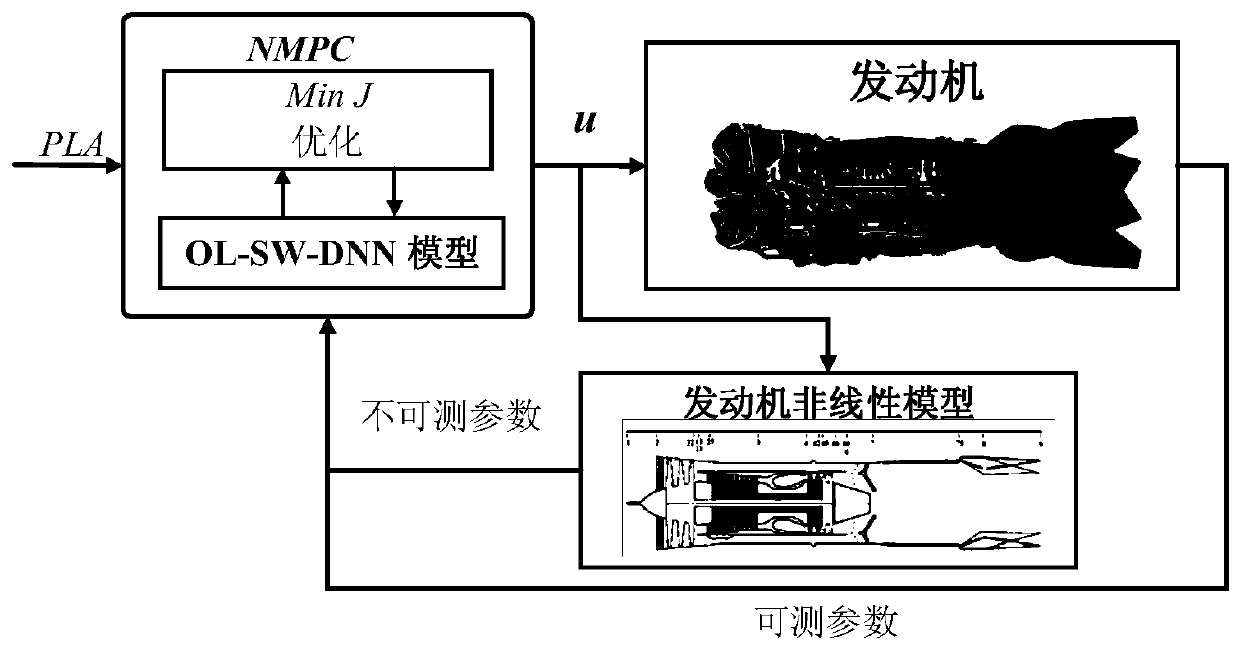

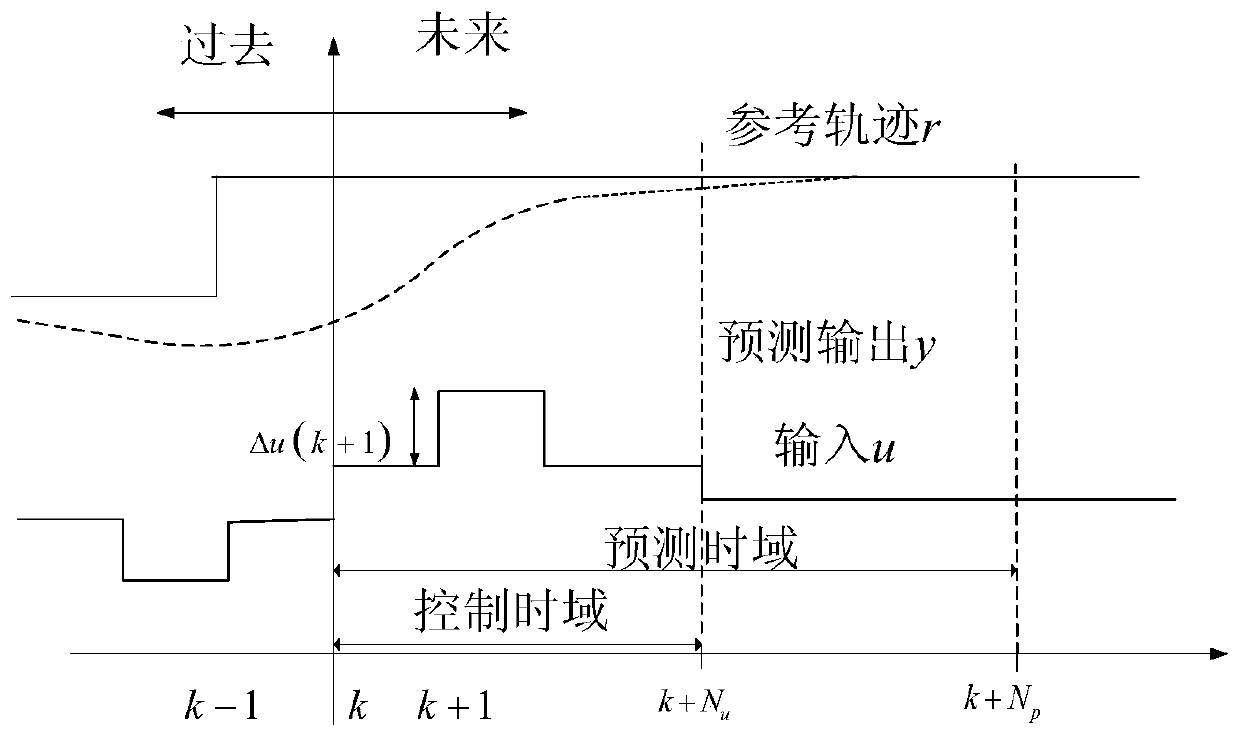

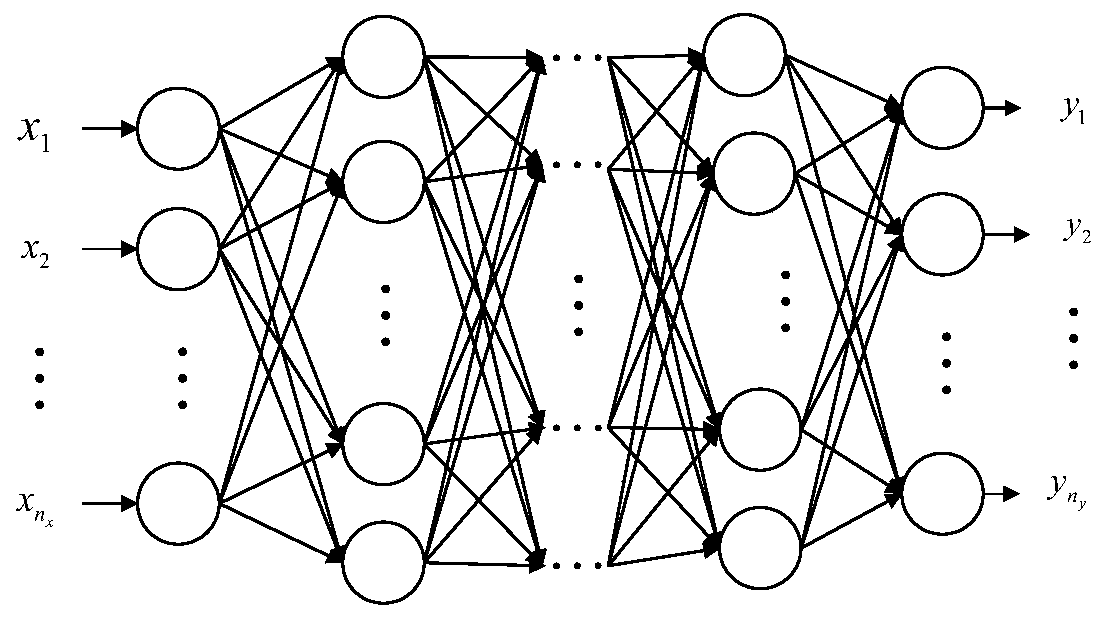

[0026] The nonlinear model predictive control system structure of the present invention is as follows figure 1 shown. The engine nonlinear model estimates unmeasurable parameters, and the NMP module includes an optimization submodule and a prediction model submodule. The present invention uses an online sliding window deep neural network (OL-SW-DNN) as a prediction model, which is better than traditional neural networks and support vector regression And other shallow network structures have strong fitting ability and improve the prediction accuracy. In the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com