Testing device and method for simulating flowback performance of well soaking of fracturing well

A test device and technology for fracturing wells, applied in the field of hydraulic fracturing, can solve the problems of not considering the complex fracture network state, water production reduction, low flowback rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0050] Such as Figure 1-5 As shown, a simulated fracturing well brine well flowback performance testing device of the present invention includes a fracturing fluid tank 2, a flowback fracturing fluid tank, a hydraulic fracturing pump 5, a flowback fluid collection beaker 9, a brine well flowback row test system 10;

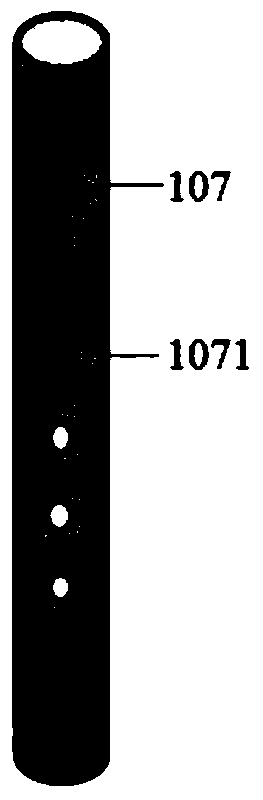

[0051] The brine well flowback testing system 10 includes a casing 105 and an acoustic wave testing device 102, a temperature control device 103, a fracturing string 107, and a square rock block 108 arranged in the casing 105;

[0052] Stress loading plate 101, hydraulic block 106 are all arranged successively between the four surfaces of described square rock block 108 and the inwall of described casing 105;

[0053] The stress loading plate 101 can guarantee that its area is greater than or equal to the single-sided area of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com