Preparation method of 3,4-dimethylpyrazole and preparation method of 3,4-dimethylpyrazole phosphate

A technology of dimethylpyrazole phosphate and dimethylpyrazole, which is applied in the chemical field, can solve the problems of limited promotion, high cost of raw materials, harsh reaction conditions, etc., and achieve cheap and easy-to-obtain raw materials, high-quality products, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

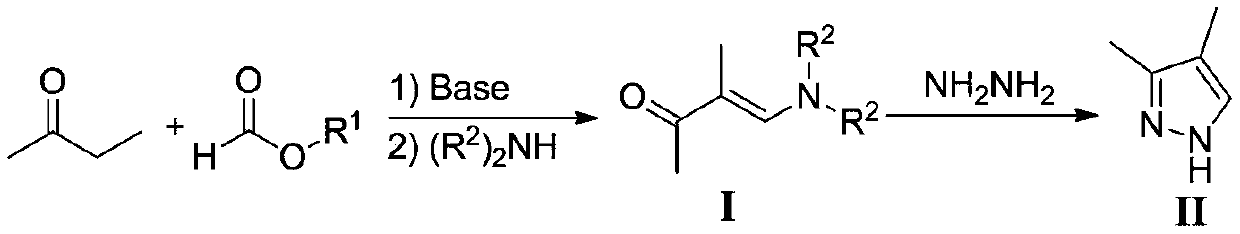

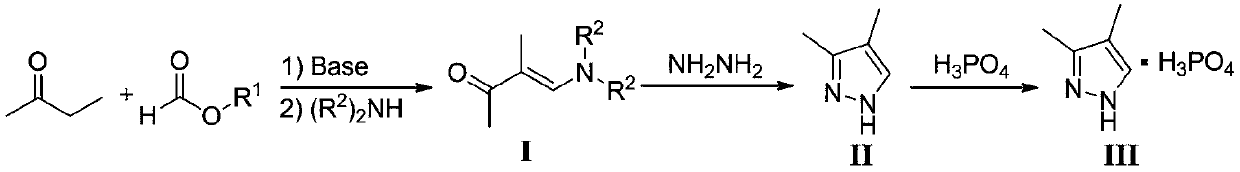

[0048] Example 1 Preparation of 1-dimethylamino-2-methyl-1-buten-3-one

[0049] Add 60g of 2-butanone, 100g of methyl formate and 400g of toluene into the reaction flask, add 81g of sodium methoxide solid in batches under control of the internal temperature at 0-15°C, and then react at 10-35°C for 4 hours. Add 30% aqueous solution of dimethylamine hydrochloride (88g of dimethylamine hydrochloride dissolved in 205g of water) to the reaction solution at 15-35°C, react at 10-35°C for 3 hours after the dropwise addition is completed, and then separate the layers. The aqueous phase was extracted once with toluene, and the organic layers were combined and concentrated to obtain an oil.

Embodiment 2

[0050] Example 2 Preparation of 3,4-dimethylpyrazole

[0051] Add the 1-dimethylamino-2-methyl-1-buten-3-one prepared in Example 1 into a three-necked flask, slowly add 52 g of 80% hydrazine hydrate solution dropwise, and then control the temperature at 15-35°C Slowly add hydrochloric acid dropwise to adjust the pH value to 7-9, keep the reaction at 15-45°C for 2 hours, slowly add 20% NaOH aqueous solution dropwise to adjust the pH value to 7-10, add 140g toluene, and statically separate to obtain an organic layer , the solvent was distilled off under reduced pressure to obtain the crude product 3,4-dimethylpyrazole with a yield of 79%, which could be directly used in the next step of salt formation.

Embodiment 3

[0052] Example 3 Preparation of 3,4-dimethylpyrazole phosphate

[0053] Dissolve the 3,4-dimethylpyrazole obtained in Example 2 in 144g of methanol, add 96g of 85% phosphoric acid at room temperature to adjust the pH value to 3-7, continue to stir and react at 15-25°C for 2 hours, filter, and dry. 110 g of 3,4-dimethylpyrazole phosphate white solid was obtained, with a total yield of 68%. 1H NMR (400MHz, DMSO-d6) δ=11.03(brs,4H),7.26(s,1H),2.10(s,3H),1.91(s,3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com