Oily industrial wastewater treatment device and treatment method

A technology for sewage treatment equipment and industrial wastewater, applied in the petroleum industry, multi-stage water treatment, water treatment parameter control, etc., can solve the problems of high operating cost, manual on-site operation, odor volatilization, etc., to improve operating efficiency and save money. The effect of infrastructure investment and reduction of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

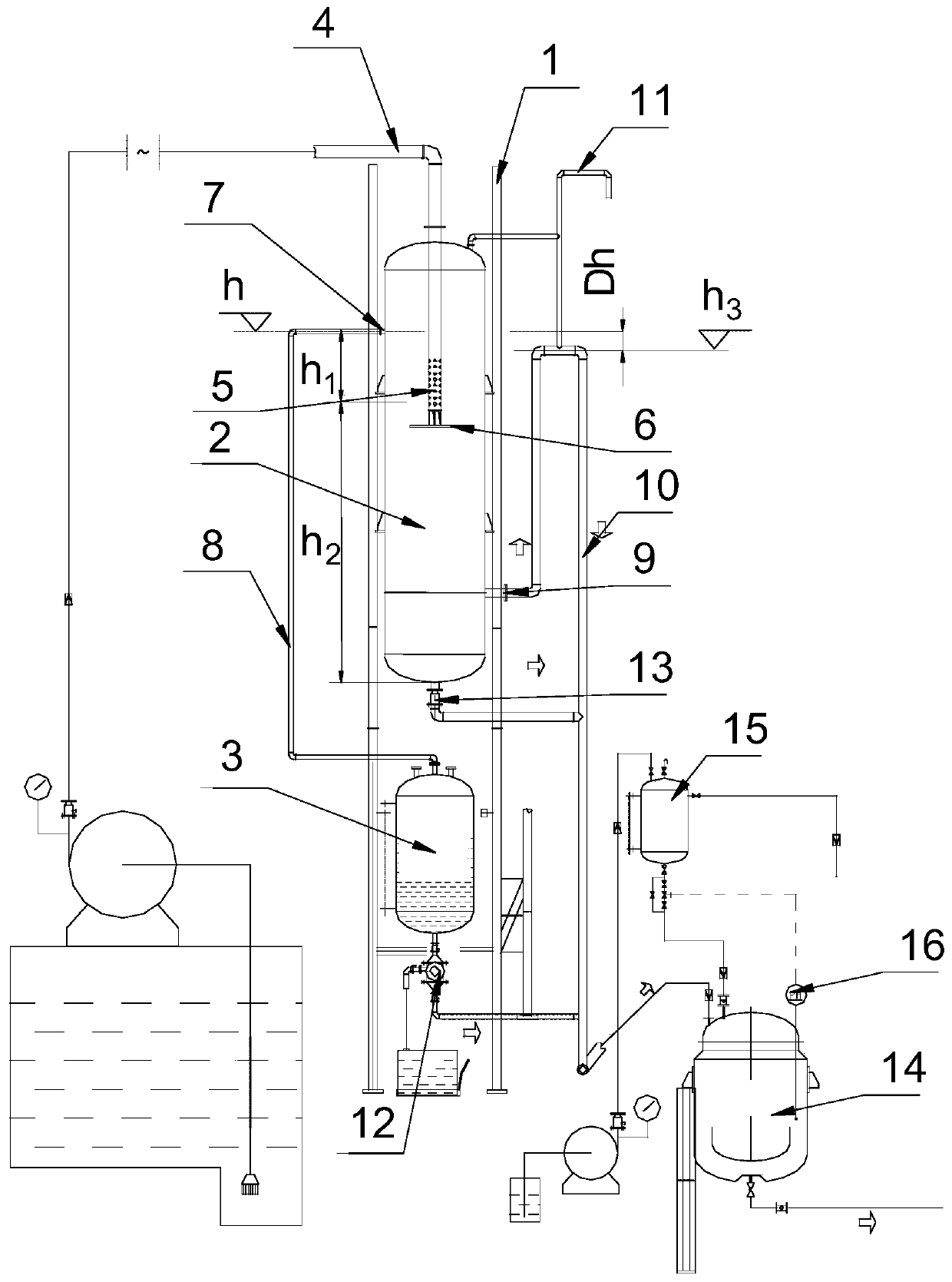

[0027] Such as figure 1 An oil-containing industrial wastewater treatment device is shown, which includes a frame body 1, an oil-water separation head tank 2 and a floating oil receiving tank 3. The oil-water separation head tank 2 is arranged on the upper part of the frame body 1, and the floating oil receiving tank 3 is arranged The lower part of the frame body 1, the top of the oil-water separation header tank 2 is connected to the oily sewage inlet pipe 4, the oily sewage water inlet pipe 4 extends to the inside of the oil-water separation header tank 2, and the oily sewage outlet 5 is a porous water flow distributor. A water baffle 6 is arranged below the oily sewage water outlet 5 . One side of the oil-water separation head tank 2 is provided with an oil slick overflow port 7 above the oily sewage outlet 5, and the oil sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com