Method for preparing large-particle lithium carbonate from salt lake lithium-rich brine

A technology of large particles and lithium carbonate, which is applied in the direction of lithium carbonate; Effect of improving purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

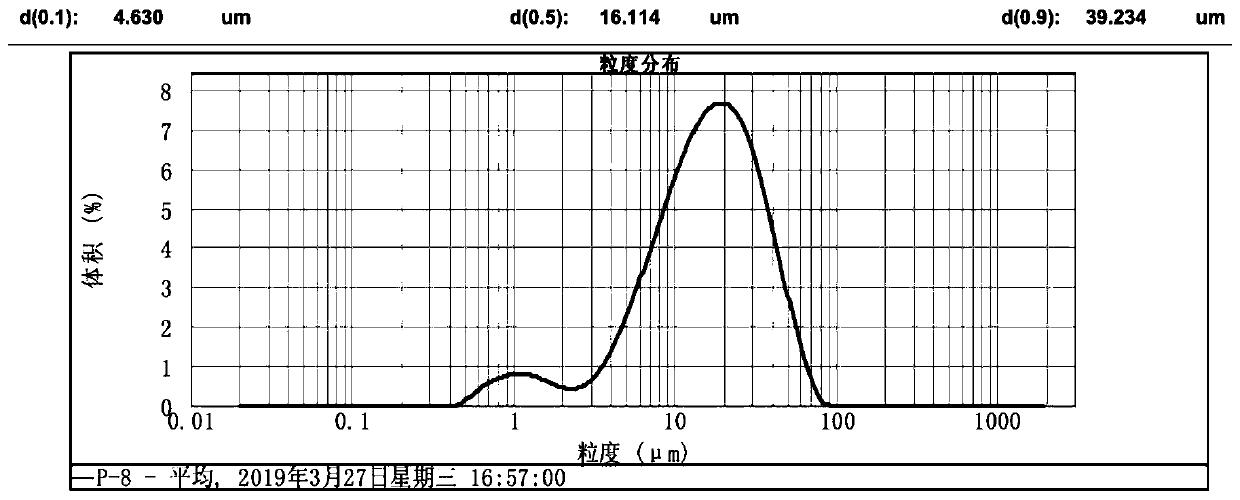

Image

Examples

Embodiment 1

[0066] A method for preparing large particles of lithium carbonate from salt lake lithium-rich brine, wherein the content of lithium ions in the lithium-rich brine of the salt lake is 2.52 wt%, the content of potassium ions is 0.25 wt%, the content of magnesium ions is 0.09 wt%, and the content of sodium ions is 0.74 wt%. wt%, the sulfate content is 0.08wt%.

[0067] Include the following steps:

[0068] Step 1: Stir and heat 180 g of salt lake lithium-rich brine to 78°C. After the heating is completed, maintain stirring and temperature and add 7.4 g of surfactant to the salt lake lithium-rich brine. The added mass of the surfactant per minute is the Said salt lake lithium-rich brine quality 0.35%, obtains the salt lake lithium-rich brine after pretreatment;

[0069] Described surfactant is the aqueous solution of polypropylene ammonium salt (molecular weight is 3~100,000 daltons), sodium lauryl sulfate and sodium hexametaphosphate, and the mass of polypropylene ammonium salt...

Embodiment 2

[0081] A method for preparing large particles of lithium carbonate from salt lake lithium-rich brine, wherein the content of lithium ions in the lithium-rich brine of the salt lake is 2.00 wt%, the content of potassium ions is 0.1 wt%, the content of magnesium ions is 0.08 wt%, and the content of sodium ions is 0.20 wt%. wt%, the sulfate content is 0.02wt%.

[0082] Include the following steps:

[0083] Step 1: Stir and heat 180 g of salt lake lithium-rich brine to 70°C. After heating, maintain stirring and temperature and add 10 g of surfactant to the salt lake lithium-rich brine. The mass of surfactant added per minute is the The quality of salt lake lithium-rich brine is 0.2%, and the pretreated salt lake lithium-rich brine is obtained;

[0084] Described surfactant is the aqueous solution of polypropylene ammonium salt (molecular weight is 3~100,000 daltons), sodium lauryl sulfate and sodium hexametaphosphate, and the mass of polypropylene ammonium salt in described surfa...

Embodiment 3

[0089] A method for preparing large particles of lithium carbonate from salt lake lithium-rich brine, wherein the content of lithium ions in the lithium-rich brine of the salt lake is 3.00 wt%, the content of potassium ions is 0.4 wt%, the content of magnesium ions is 0.1 wt%, and the content of sodium ions is 1.00 wt%. wt%, the sulfate content is 0.10wt%.

[0090] Include the following steps:

[0091] Step 1: Stir and heat 180 g of salt lake lithium-rich brine to 85°C. After the heating is completed, maintain stirring and temperature and add 10 g of surfactant to the salt lake lithium-rich brine. The added mass of the surfactant per minute is the The quality of salt lake lithium-rich brine is 0.5%, and the salt lake lithium-rich brine after pretreatment is obtained;

[0092] Described surfactant is the aqueous solution of polypropylene ammonium salt (molecular weight is 3~100,000 daltons), sodium lauryl sulfate and sodium hexametaphosphate, the quality of polypropylene ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com