A thin-walled capillary electrically assisted drawing and charging device and method

A capillary electrical and electrical device technology, applied in the field of thin-walled capillary electrical assisted drawing and powering devices, can solve the problems that the thin-walled capillary electrical assisted drawing and setting can not be used for explanation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

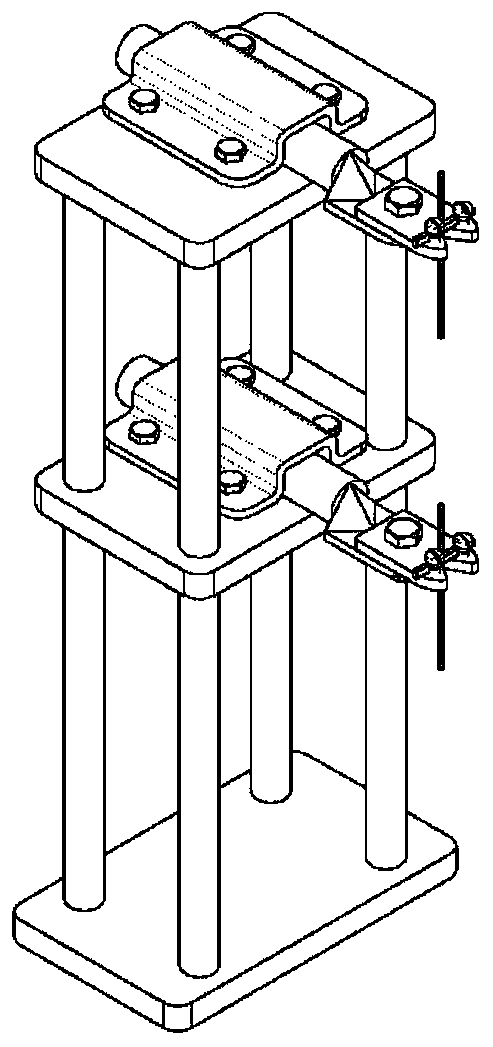

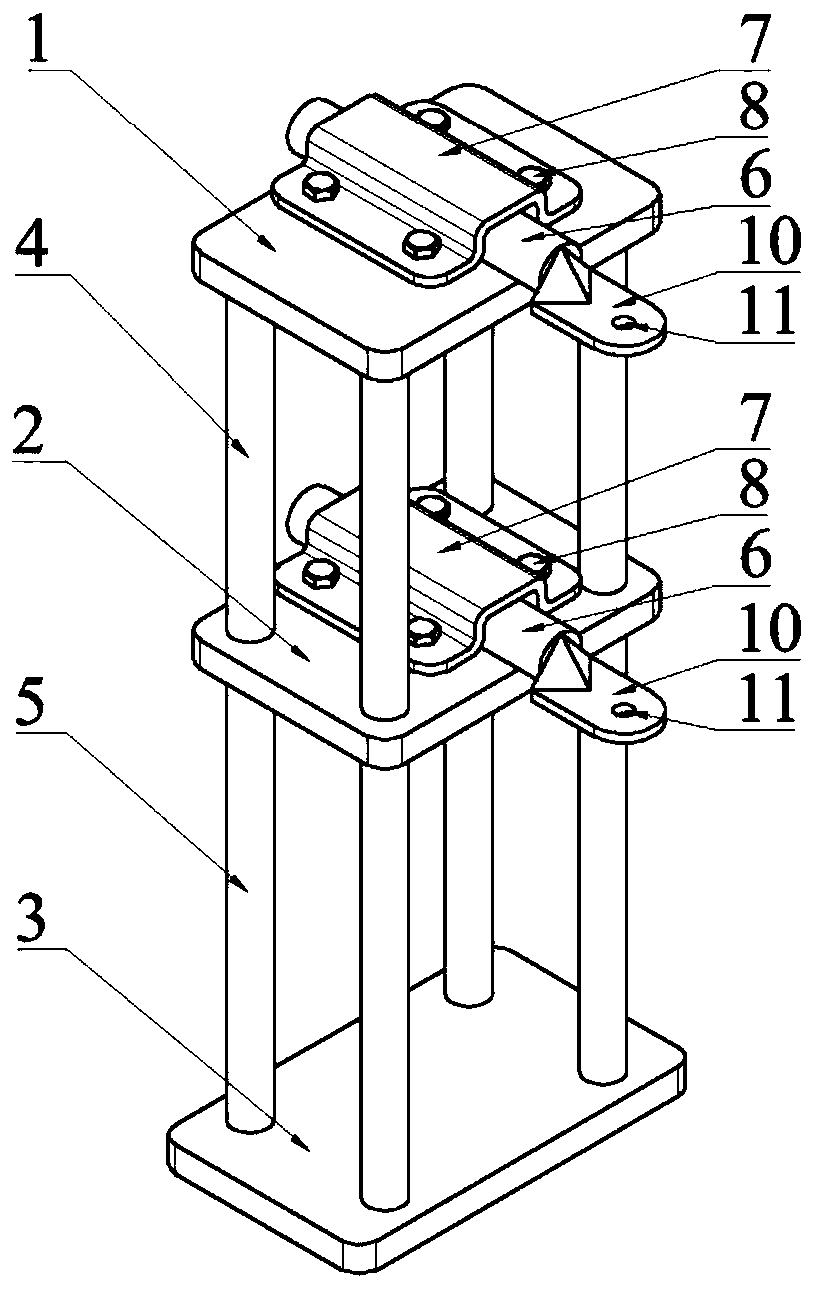

[0031] Such as figure 1 As shown, the thin-walled capillary electrically assisted drawing and powering device of the present invention includes a cable fixing device and an electrode contacting device.

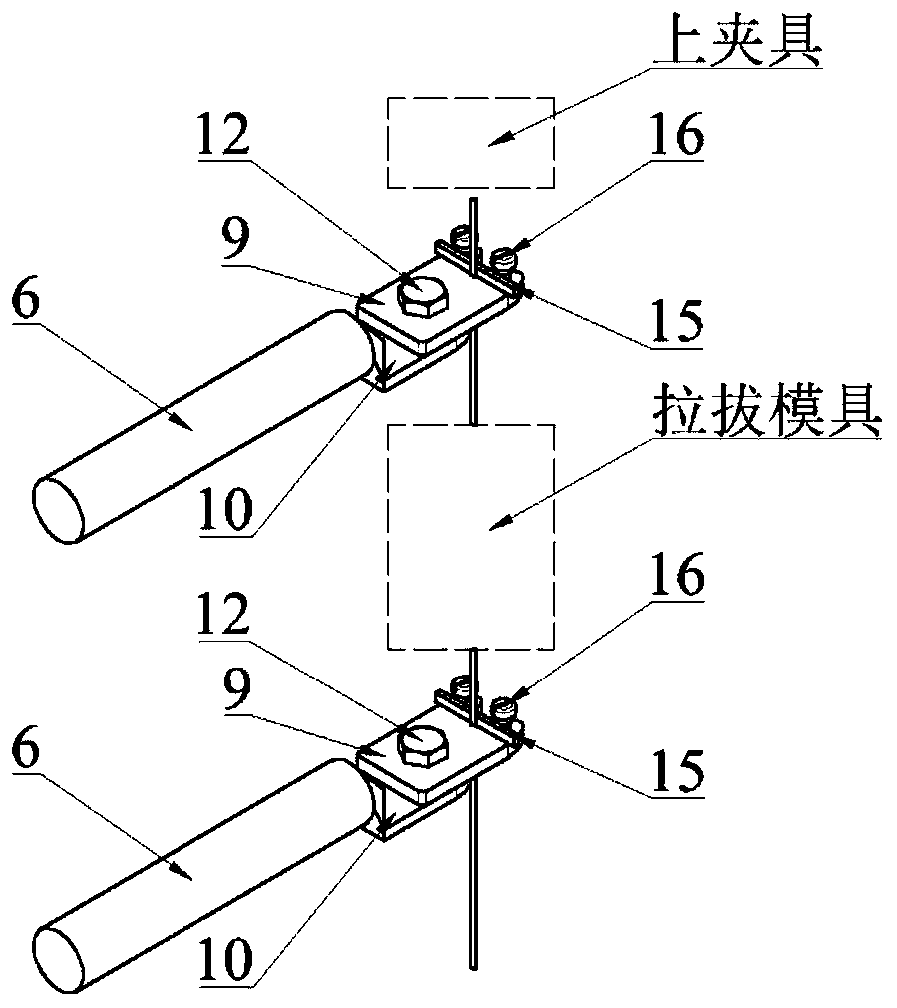

[0032] Such as figure 2 As shown, the cable fixing device includes an upper mold base 1, a lower mold base 2 and a base 3 installed sequentially from top to bottom. The upper mold base 1 and the lower mold base 2 are fixedly connected by four upper support columns 4, and the lower mold base 2 and The base 3 is fixedly connected by 4 lower supporting columns 5, and the top surface of the upper mold base 1 and the lower mold base 2 are each provided with a cable splint 7 for fixing the cable 6.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com