Variable-gain brake command sensor and method for determining design parameter

A braking command and sensor technology, applied in the field of variable gain braking command sensor and determining design parameters, can solve the problems of low braking efficiency and high human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

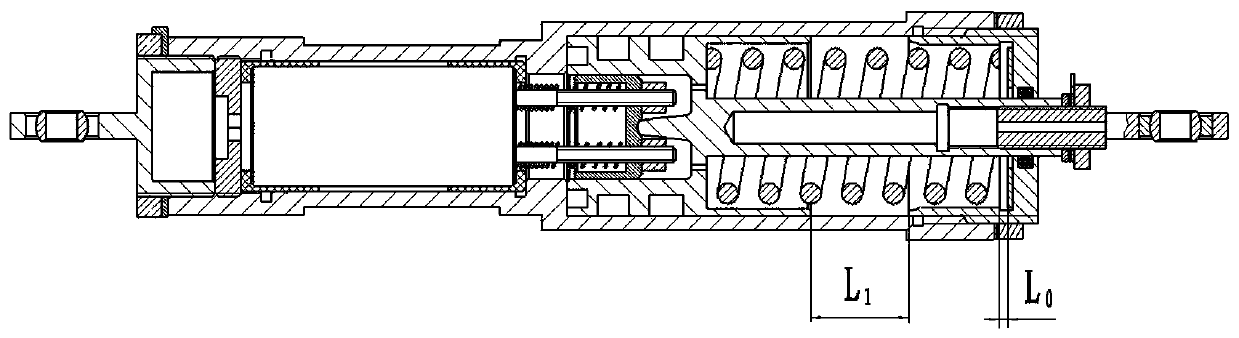

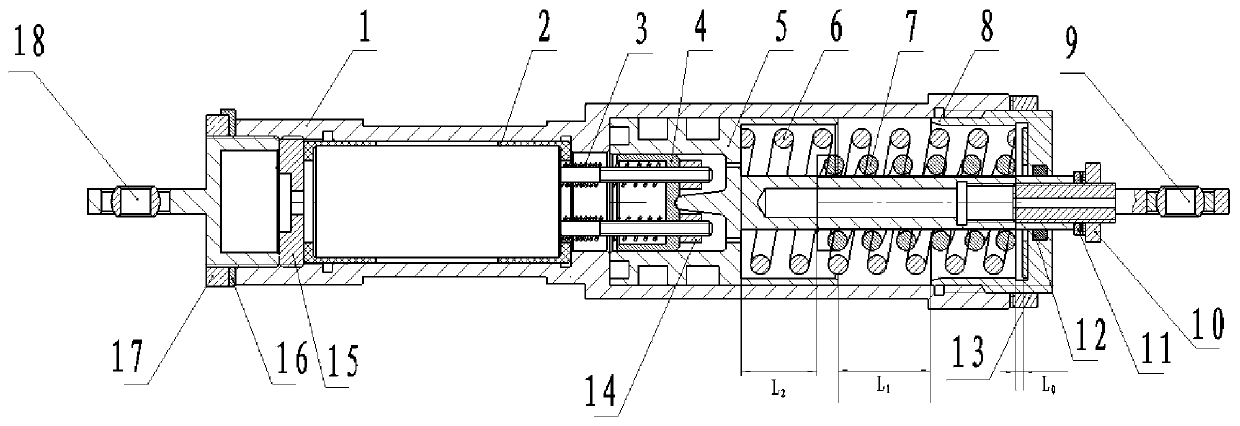

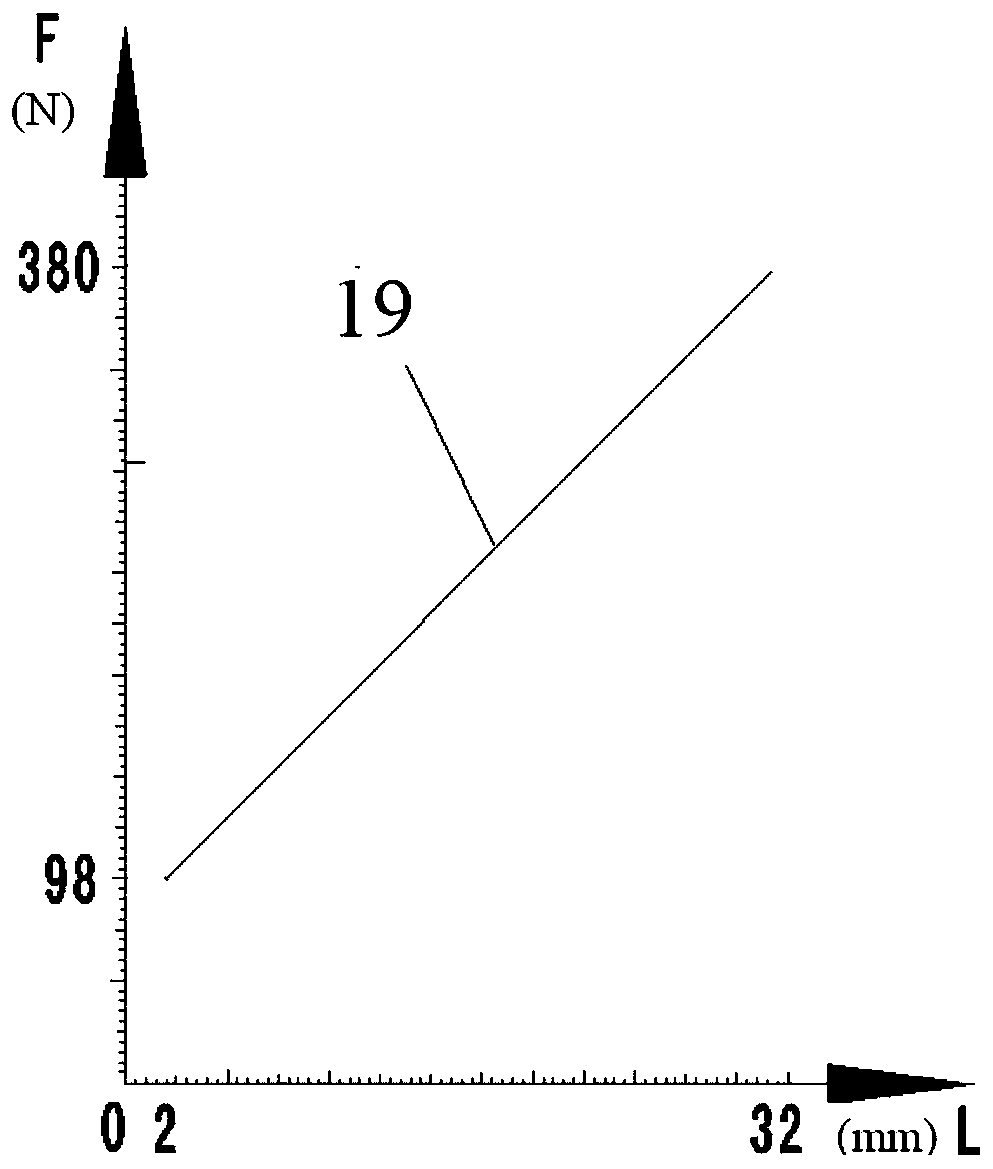

[0098] This embodiment is a variable gain brake command sensor, which includes a housing 1, a positioning sleeve 2, a return spring 3, a reset piston 4, a force-sensing piston 5, a first force-sensing spring 6, a second force-sensing Spring 7, stop sleeve 8, movable bracket assembly 9, lock nut 10, washer 11, sealing ring 12, stop sleeve nut 13, reset piston fixing nut 14, top sleeve 15, washer 16, nut 17 and fixed bracket assembly 18. in:

[0099] The brake command sensor is obtained after improving the prior art. The brake command sensor includes a movable bracket assembly 9, a lock nut 10, a top sleeve 15, a fixed bracket assembly 18, a housing 1, a positioning sleeve 2, a return spring 3, a reset piston 4, a force-sensing piston 5, and a first force-sensing spring 6. The second force-sensing spring 7 and the stop sleeve 8. The improvement of this embodiment over the prior art is that a second force-sensing spring 7 is added to the brake command sensor. The parts of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com