Flexible connecting structure of prefabricated component and building main body

A technology of prefabricated components and building main body, applied in the direction of building structure, building, building components, etc., can solve the problems of inconvenient construction, increased design rigidity, high overall rigidity, etc., and achieve the effect of convenient construction, simple structure and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

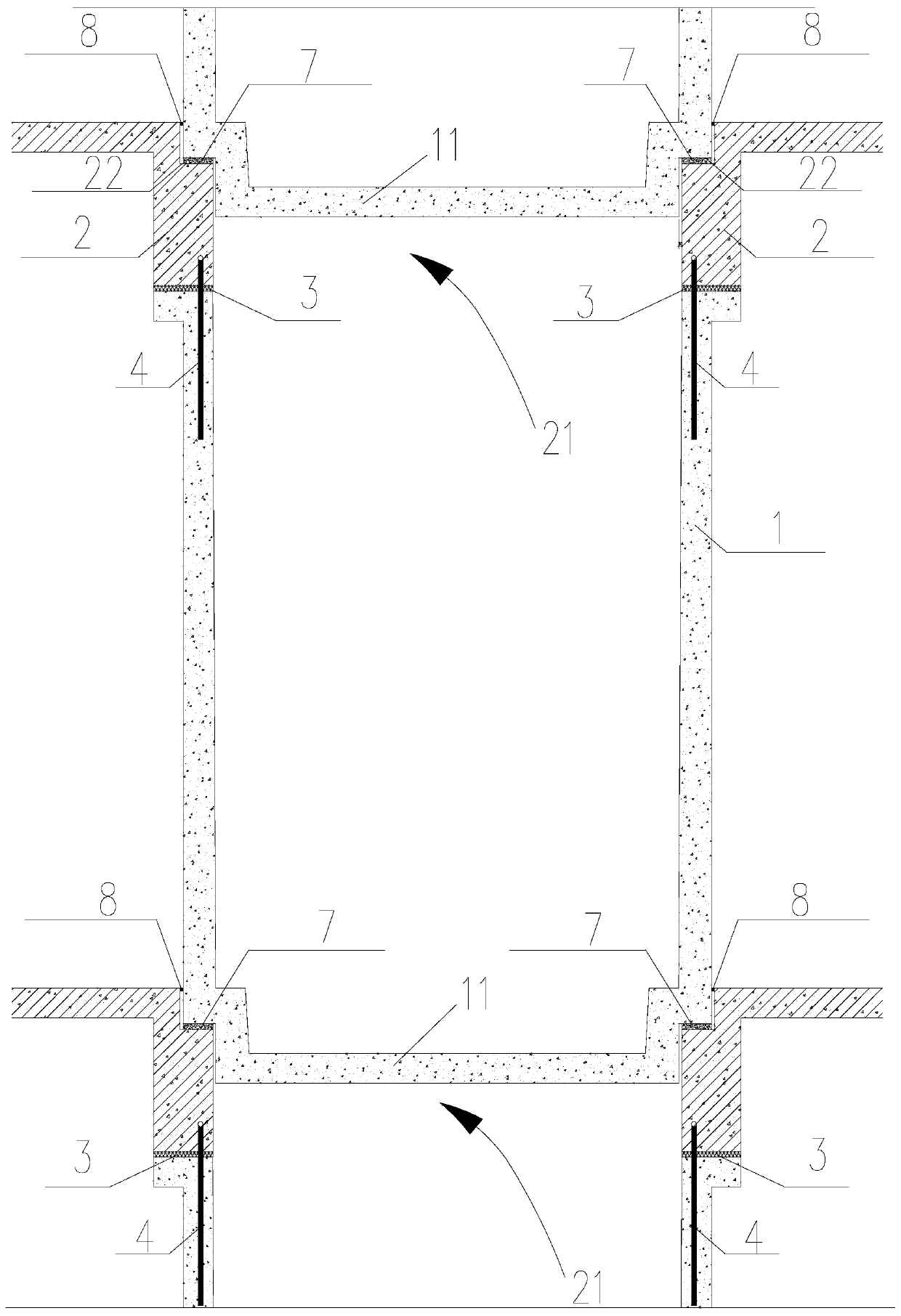

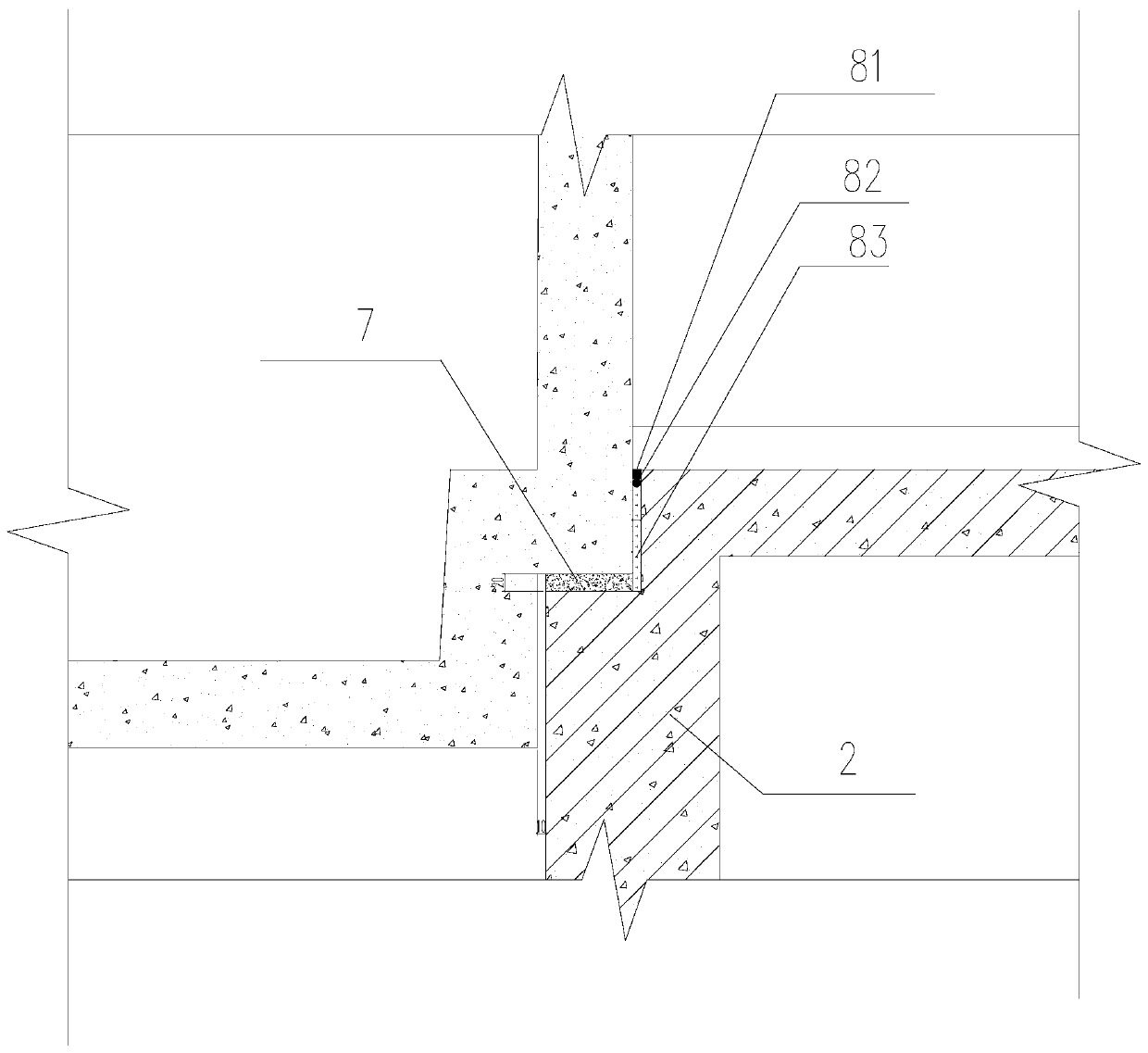

[0030] Such as figure 1 As shown, the flexible connection structure between the prefabricated components and the building body in this embodiment includes multiple layers of cast-in-place building bodies 2 arranged at intervals up and down, and prefabricated components 1 are connected between two adjacent cast-in-place building bodies 2 . In this embodiment, the main body 2 of the cast-in-place building is a floor slab, and the floor slab is provided with a square mortise 21, and the groove wall of the mortise 21 is enclosed and reinforced by four floor beams. The prefabricated component 1 is a prefabricated toilet. The lower parts of the four side walls of the prefabricated component 1 shrink inwardly to form a tenon 11 matching with the tenon groove 21, and the upper part of the prefabricated component 1 forms the main body of the prefabricated component.

[0031] The prefabricated component 1 is connected to the main body 2 of the lower cast-in-place building through mortis...

Embodiment 2

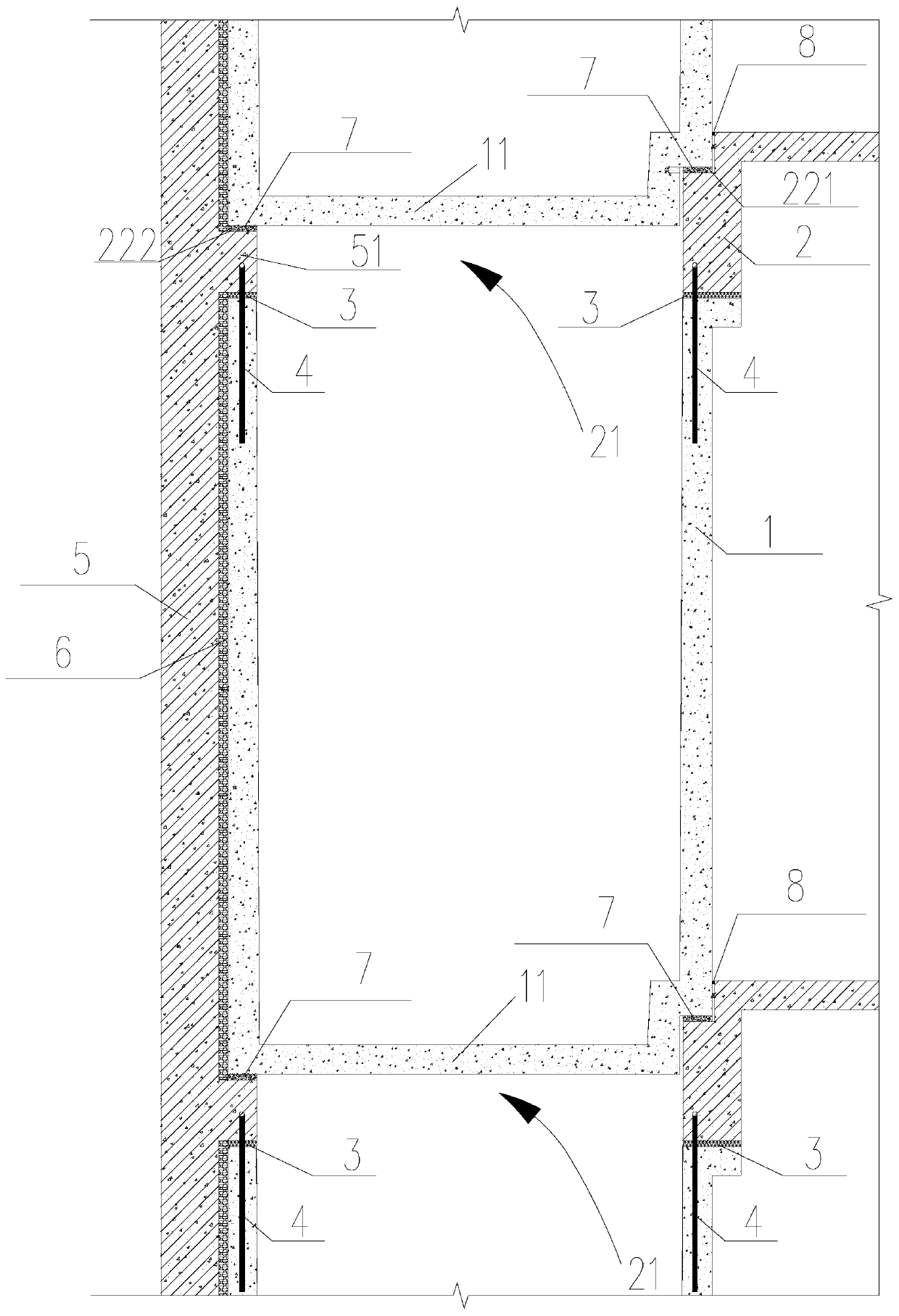

[0043]The flexible connection structure between the prefabricated components and the main body of the building in this embodiment includes multi-layer cast-in-place building main bodies 2 arranged at intervals up and down, and prefabricated components 1 are connected between two adjacent cast-in-place building main bodies 2 . In this embodiment, the main body 2 of the cast-in-place building is a floor slab.

[0044] The outer wall of a side wall of the prefabricated component 1 is provided with a cast-in-place shear wall 5 connecting the upper and lower floors of the cast-in-place building main body 2, and the connection between the prefabricated component 1 and the cast-in-place shear wall 5 is provided with a The shear wall 5 connects the second flexible layer 6 of stiffness. The second flexible layer 6 is a polystyrene foam layer, and the thickness of the second flexible layer 6 is 20mm-30mm. The upper and lower ends of the cast-in-place shear wall 5 are provided with pick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com