Accurate control device for high-speed railway bridge pier column steel bar protective layer

A steel protective layer, high-speed railway technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of difficult control of concrete protective layer, affecting the construction quality of piers and columns, and achieves easy installation and disassembly, low production cost, and remarkable effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing:

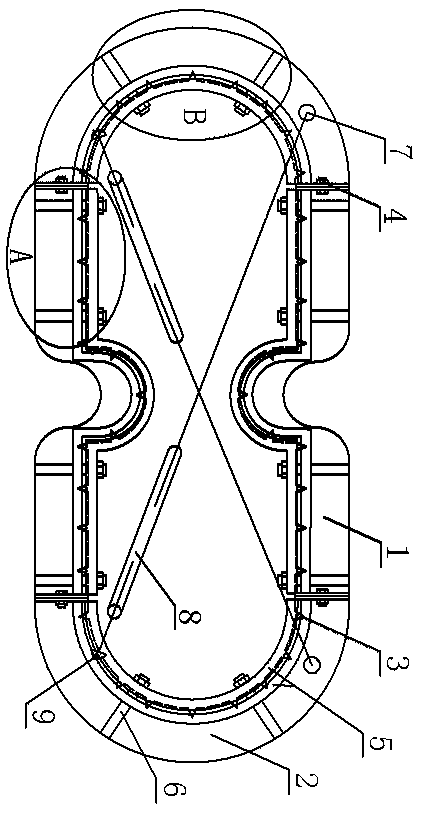

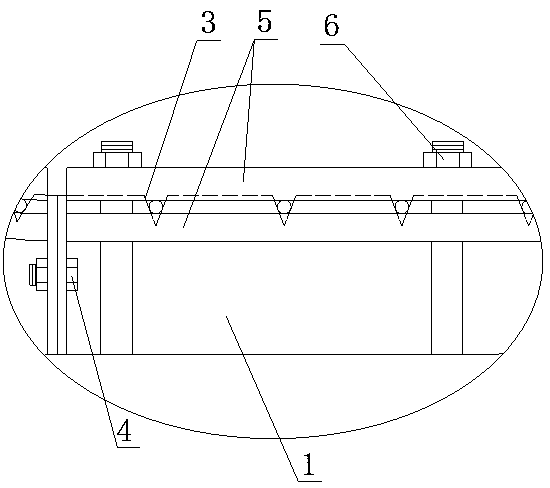

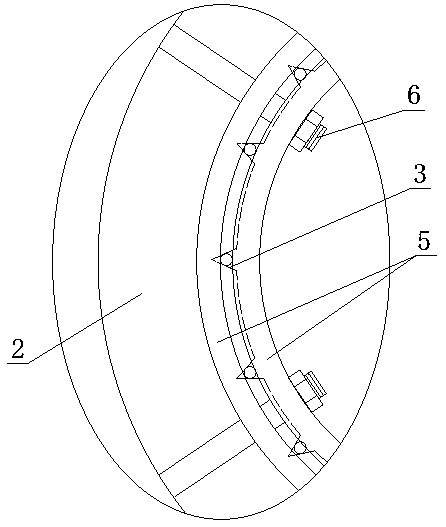

[0013] Two straight-shaped skeletons 1 and two arc-shaped skeletons 2 are fixedly connected at intervals by connecting bolts 4 to form an arc-shaped spacer skeleton, and two straight-shaped skeletons 1 are respectively provided with two inner and outer straight splints 5 at two places, Two arc-shaped fixed splints 5 inside and outside are respectively arranged at one place on the two arc-shaped skeletons 2, and the inner and outer fixed splints 5 are fixed by tightening bolts 6, and the middle parts of the two straight-shaped skeletons 1 are respectively bent inward to leave drainage grooves. Limiting slots 3 are set on the inner side of the frame according to the steel bar intervals required by the design. The limiting slots 3 are V-shaped, and steel wire ropes 7 are fixed on the limiting frame.

[0014] When using the present invention, the straight frame and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com