Circular seam type bottom-blowing gas supply brick

An air supply brick and annular seam technology, applied in the field of metallurgy, can solve the problems of funnel-shaped erosion of bottom blowing nozzles, easy blockage of pipeline pressure loss, high bottom blowing flow rate and low flow rate, etc. Large adjustment range, reduced friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the present invention and together with the embodiments of the present invention are used to explain the principles of the present invention and are not intended to limit the scope of the present invention.

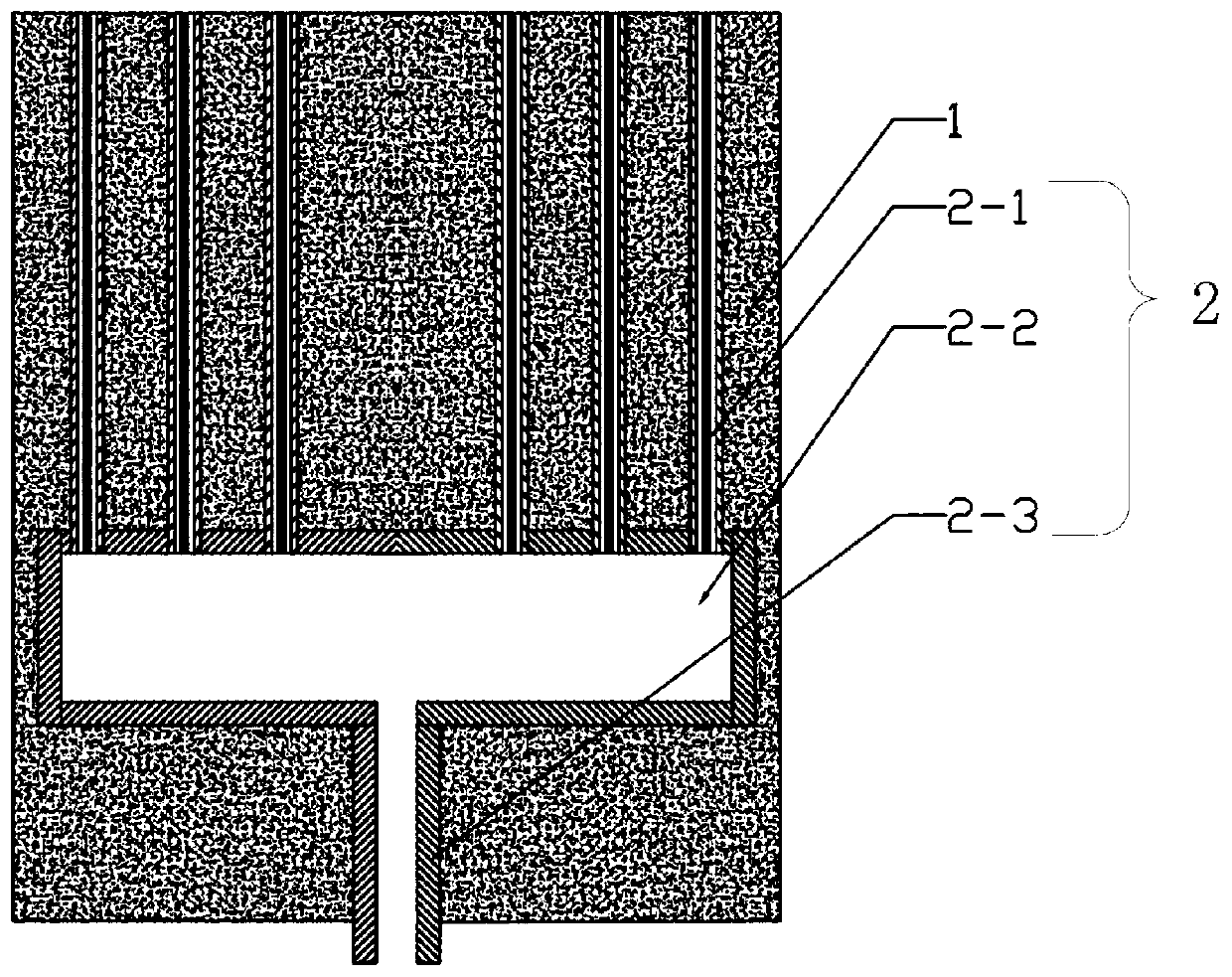

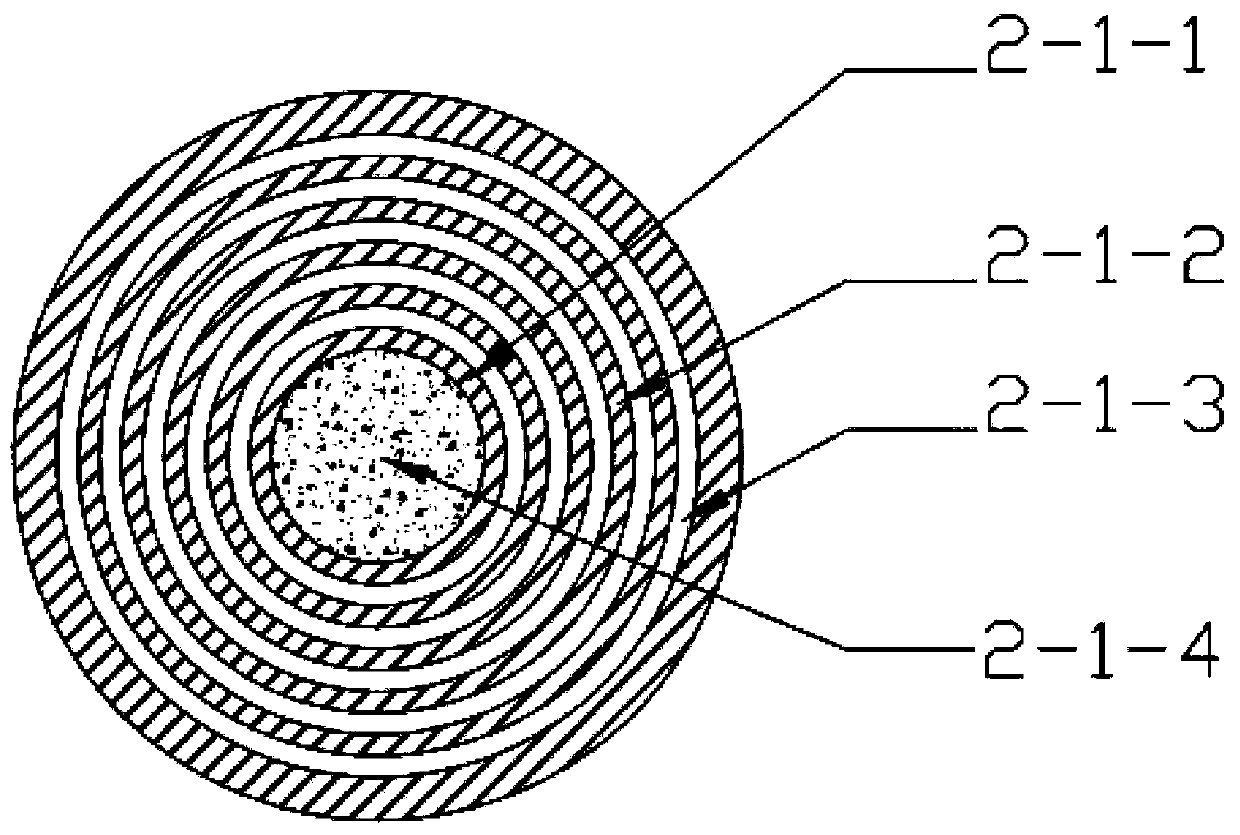

[0034] A specific embodiment of the present invention discloses a circular seam type bottom-blown air supply brick, such as Figure 1-3 As shown, it includes a main body 1 and a gas channel 2. The gas channel 2 includes an annular seam outlet pipe 2-1, a gas distribution chamber 2-2, and an air inlet pipe 2-3. The annular seam outlet pipe 2-1 includes a central pipe 2- 1-1, outer casing 2-1-2 and ring seam 2-1-3.

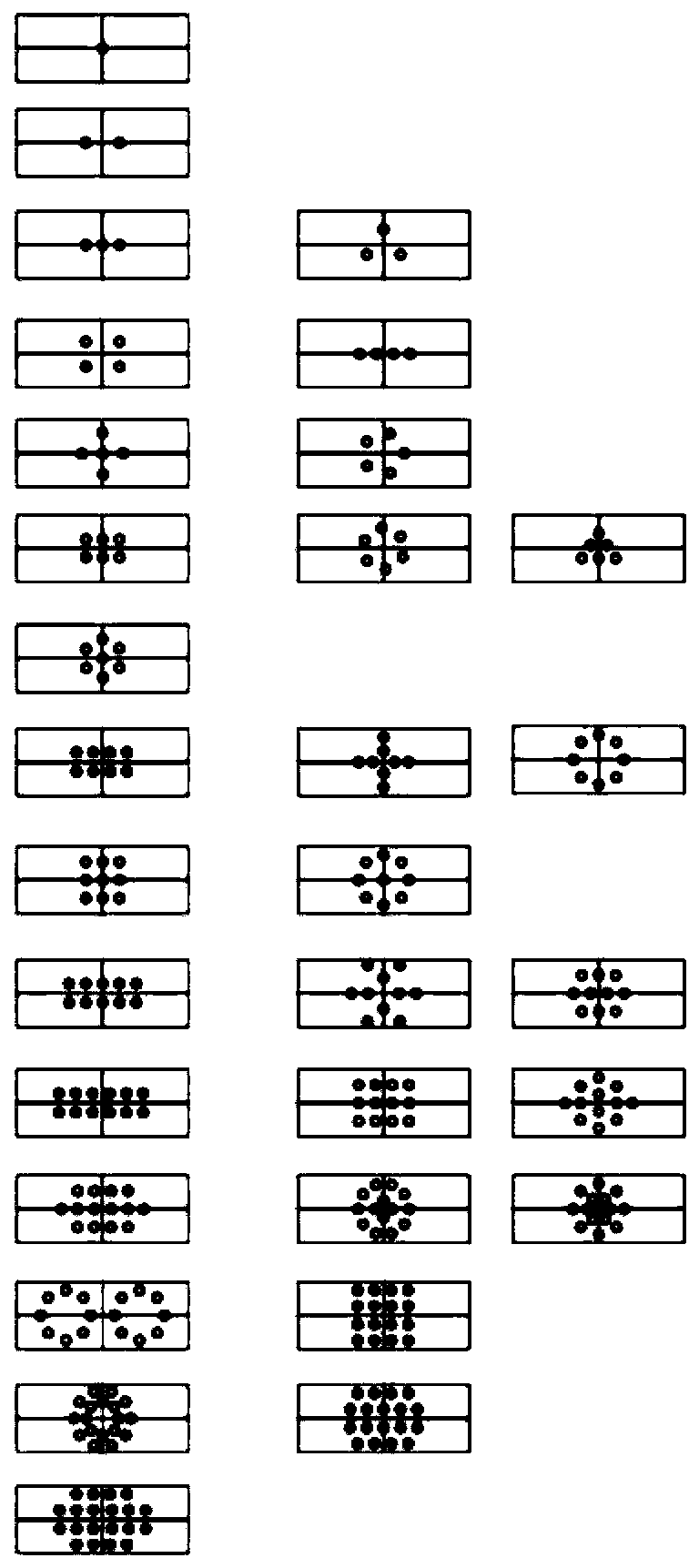

[0035] In the prior art, for the blowing of bottom blowing gas, under the condition of a certain pressure, the outlet area determines the gas flow rate. In order to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com