A kind of high-adhesion paint with flame-retardant and anti-rust properties and preparation method thereof

A high-adhesion, anti-rust technology, used in anti-corrosion coatings, fire-retardant coatings, wax coatings, etc., can solve the problems of performance to be improved, environmental pollution, high price, etc., to enhance market competitiveness and application scope, improve high performance. The effect of adhesion and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

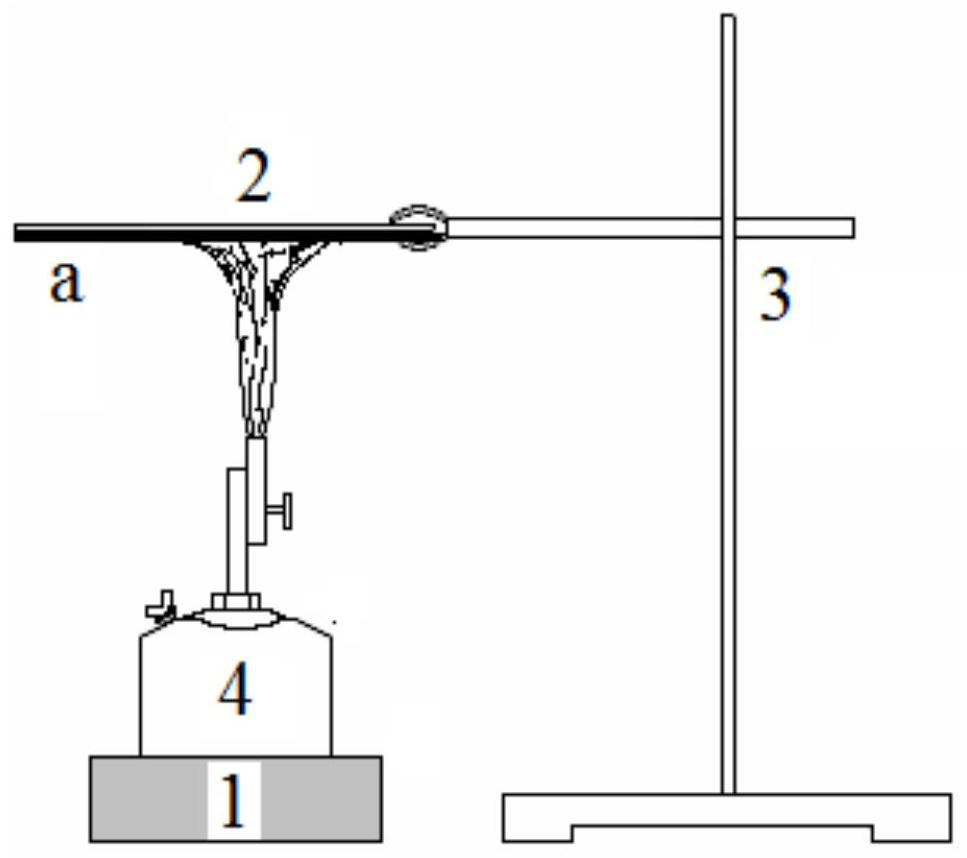

Image

Examples

Embodiment 1

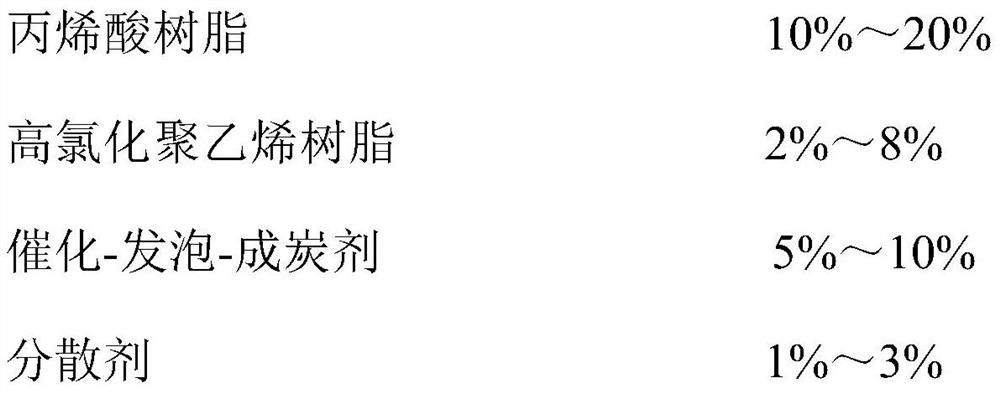

[0029] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0030]

[0031]

[0032]The acrylic resin is industrially pure; the high-chlorinated polyethylene resin is industrially pure; the catalyst-foaming-char-forming agent is a mixture of ammonium polyphosphate, melamine and pentaerythritol, the quality of ammonium polyphosphate, melamine and pentaerythritol Ratio 1:1:1, ammonium polyphosphate, melamine and pentaerythritol are industrial pure; the dispersant is F-30 dispersant, which is industrial pure; the mineral oil is industrial pure; the anti-sedimentation agent is F118 anti-settling agent The sedimentation agent is industrially pure; the steel slag fine powder is hot stuffy slag fine powder with a particle size of 25 μm to 45 μm; the tailings slag fine powder has a particle size of 25 μm to 45 μm, and the graphene oxide is industrial pure.

[0033] (1) Use a constant temperature magn...

Embodiment 2

[0037] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0038]

[0039]

[0040] The acrylic resin is industrially pure; the high-chlorinated polyethylene resin is industrially pure; the catalyst-foaming-char-forming agent is a mixture of ammonium polyphosphate, melamine and pentaerythritol, the quality of ammonium polyphosphate, melamine and pentaerythritol Ratio 3:1:3, ammonium polyphosphate, melamine and pentaerythritol are industrial pure; The dispersant is F-30 dispersant, which is industrial pure; The mineral oil is industrial pure; The anti-settling agent is F118 anti-settling agent The precipitating agent is industrially pure; the steel slag fine powder is air-quenched slag fine powder with a particle size of 25 μm to 45 μm; the tailings slag fine powder has a particle size of 25 μm to 45 μm, and the graphene oxide is industrial pure.

[0041] (1) Use a constant temperature magnet...

Embodiment 3

[0045] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0046]

[0047] The acrylic resin is industrially pure; the high-chlorinated polyethylene resin is industrially pure; the catalyst-foaming-char-forming agent is a mixture of ammonium polyphosphate, melamine and pentaerythritol, the quality of ammonium polyphosphate, melamine and pentaerythritol Ratio 2:1:2, ammonium polyphosphate, melamine and pentaerythritol are industrial pure; the dispersant is F-30 dispersant, which is industrial pure; the mineral oil is industrial pure; the anti-sedimentation agent is F118 anti-settling agent The sedimentation agent is industrially pure; the steel slag fine powder is molten iron desulfurization slag fine powder, and its particle size is 25 μm to 45 μm; the tailings slag fine powder has a particle size of 25 μm to 45 μm, and the graphene oxide is industrial pure.

[0048] (1) Use a constant temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com