Production device and production method of functional biological fertilizer liquid

A production device and biological technology, which is applied in the field of production devices of functional biological fertilizer liquid, can solve problems such as unfavorable treatment and fertilization, and achieve the effects of convenient classification and fertilization, direct storage, and automatic collection and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

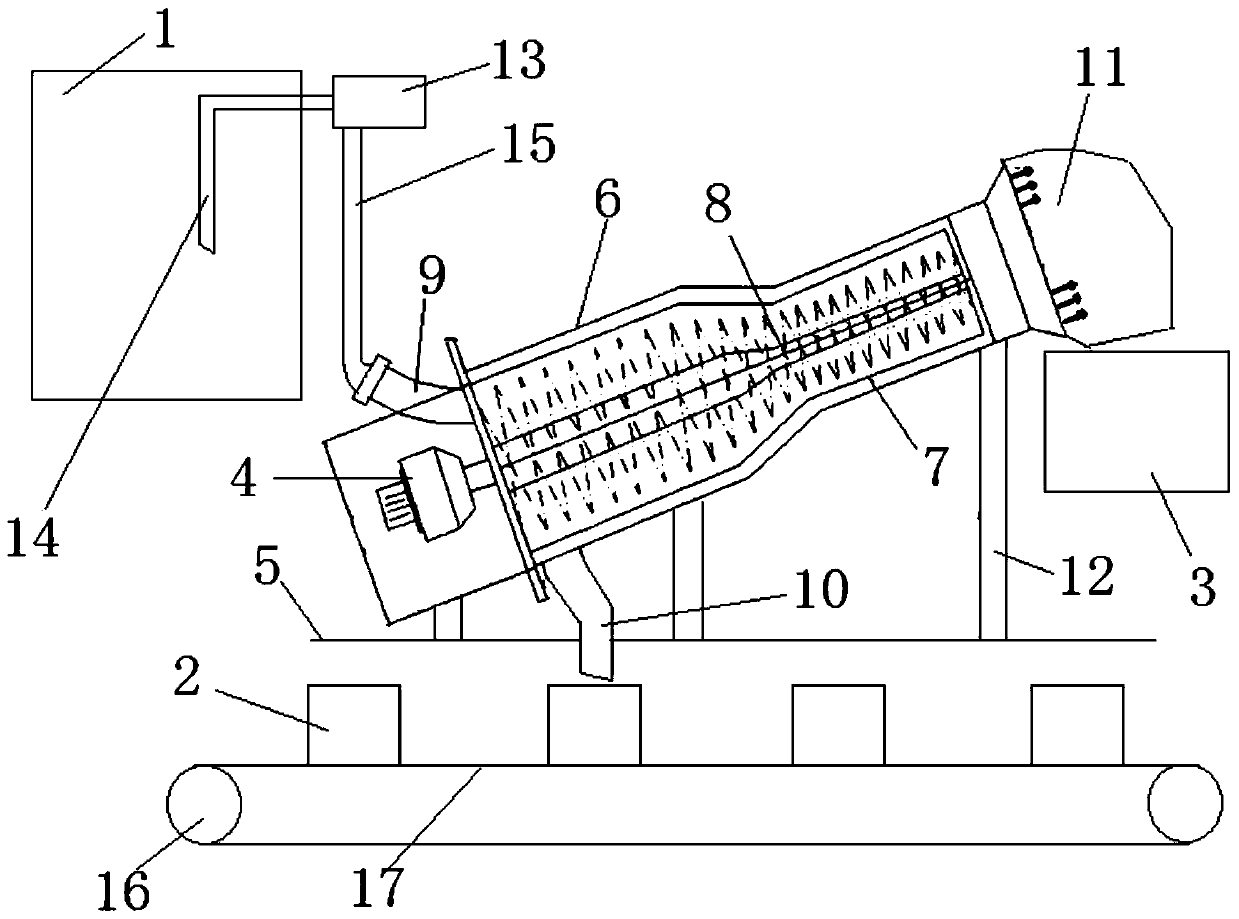

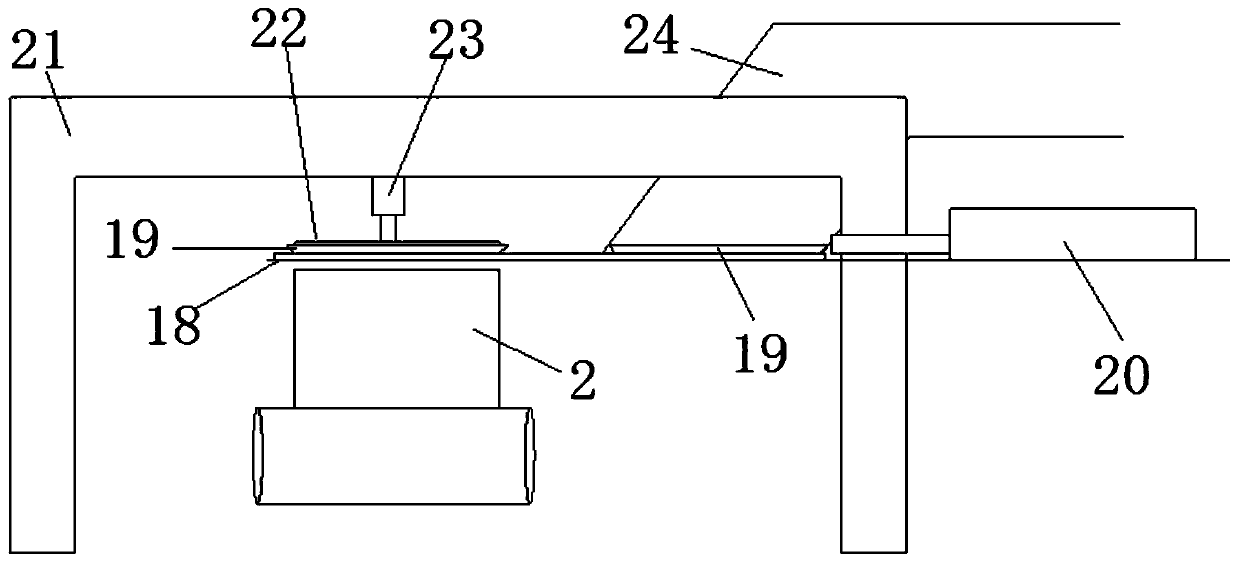

[0028] Such as figure 1 and figure 2 As shown, the solid-liquid separation mechanism includes a drive motor 4, a separation tank 6 inclined on the working platform 5, a filter screen 7 arranged in the separation tank 6 to form a solid-liquid separation space around the inner wall of the separation tank 6, and a solid-liquid separation tank. The screw propeller 8 in the separation space, the feed inlet 9 of the separation tank is located on the upper side of the bottom of the separation tank 6 and communicates with the solid-liquid separation space, and the liquid discharge port 10 of the separation tank 6 is located at the bottom of the separation tank On the lower side wall, the solid material outlet 11 of the separation tank 6 is located on the top of the separation tank, and the drive motor 4 drives the screw propeller 8 to guide the solid material from the top outlet of the solid-liquid separation space to the solid material outlet 11 of the separation tank 6 . During op...

Embodiment 2

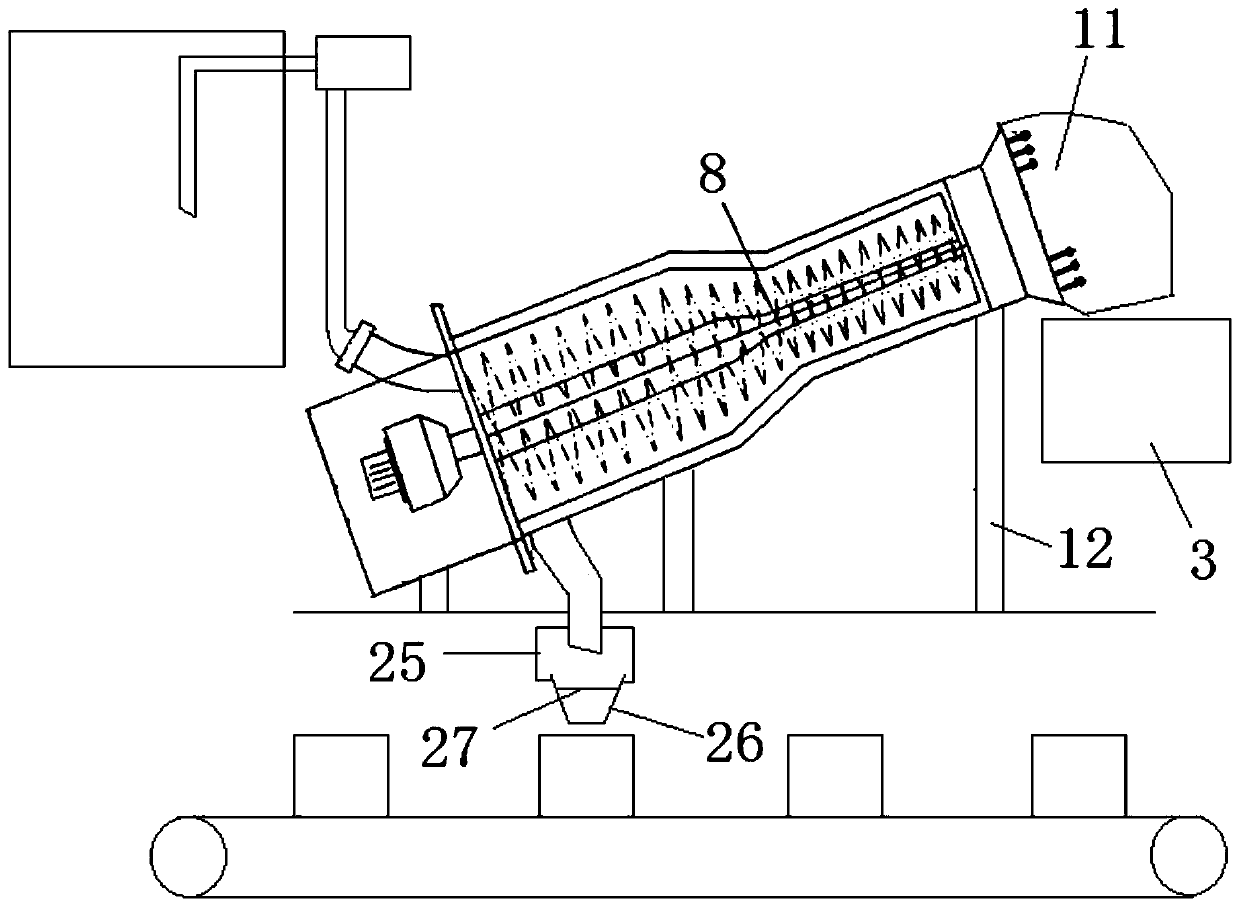

[0041] The difference between this embodiment and Embodiment 1 is that a funnel 26 and a bracket 25 for fixing the funnel are provided directly below the liquid outlet 10, and a detachable filter sheet 27 is arranged in the funnel. Specifically, the bracket is fixedly connected to the liquid outlet through fasteners, and the funnel is clipped to the bracket or detachably connected through fasteners. The biological fertilizer liquid exported from the liquid discharge port enters the funnel, and after being filtered by the filter plate, it is introduced into the biological fertilizer liquid collection tank to avoid the situation that the solid material is introduced into the biological fertilizer liquid filter tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com