Double-nozzle integrated digital double-sided inkjet printer and inkjet printing method thereof

A technology of dual nozzles and jet printers, applied in printing, typewriters, printing devices, etc., can solve the problems of labor and time consumption, occupy a large space, increase costs, etc., and achieve the goals of increasing stability, simplifying structure, and saving space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

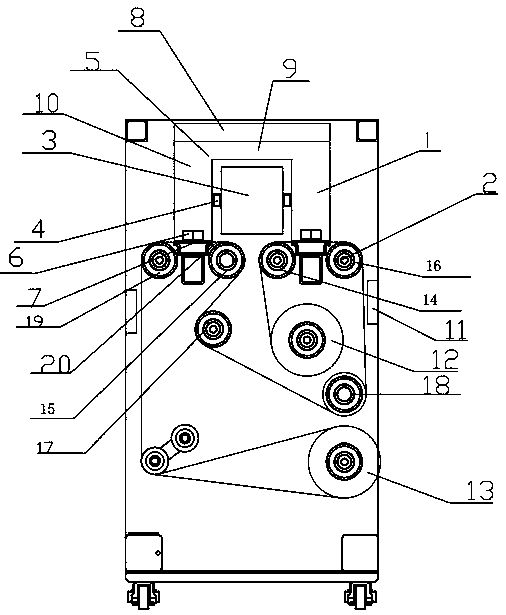

[0052] This embodiment provides an integrated digital double-sided inkjet printing machine with double nozzles, including an inkjet unit and a transmission unit. The inkjet unit includes an integrated inkjet beam and two sets of inkjet mechanisms; Two sets of inkjet tracks installed on the two sets of inkjet beams, two sets of inkjet trolleys mounted on the two sets of inkjet tracks that can reciprocate, two sets of nozzles installed on the two sets of inkjet trolleys, two sets of inkjet sprayers installed under the two sets of inkjet trolleys platform.

[0053] An inkjet driving device is arranged on the integrated inkjet painting beam, and the inkjet painting driving device is connected with two groups of inkjet painting mechanisms at the same time.

[0054] The integrated inkjet beam includes a head, and the inkjet driving device is arranged in the head.

[0055] In this embodiment, the integrated inkjet beam is arched and divided into an upper part and a lower part. The f...

Embodiment 2

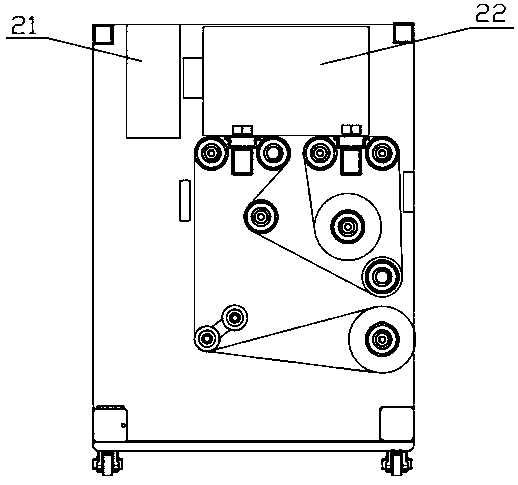

[0061] The difference between this embodiment and Embodiment 1 is that the integrated spray-painting beam is divided into a left part and a right part; Such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com