Automatic mixing and proportioning equipment for biomass charcoal and lime in phyllostachys praecox woodland

A technology of biomass charcoal and woodland, which is applied in the direction of mixers, transportation and packaging, mixer accessories, etc., can solve the problems of insufficient mixing of materials, and achieve the effects of improving productivity, avoiding leakage, and improving mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

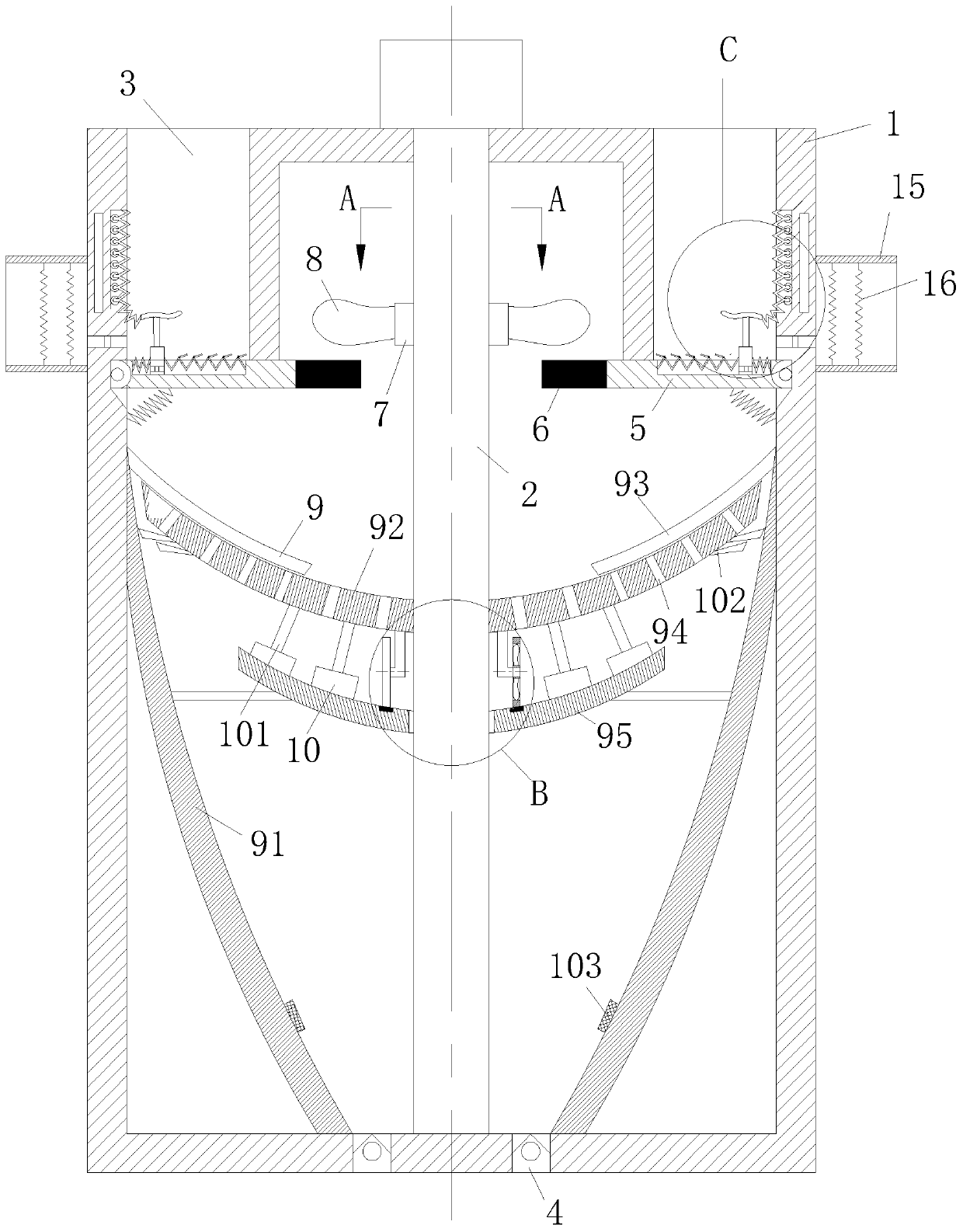

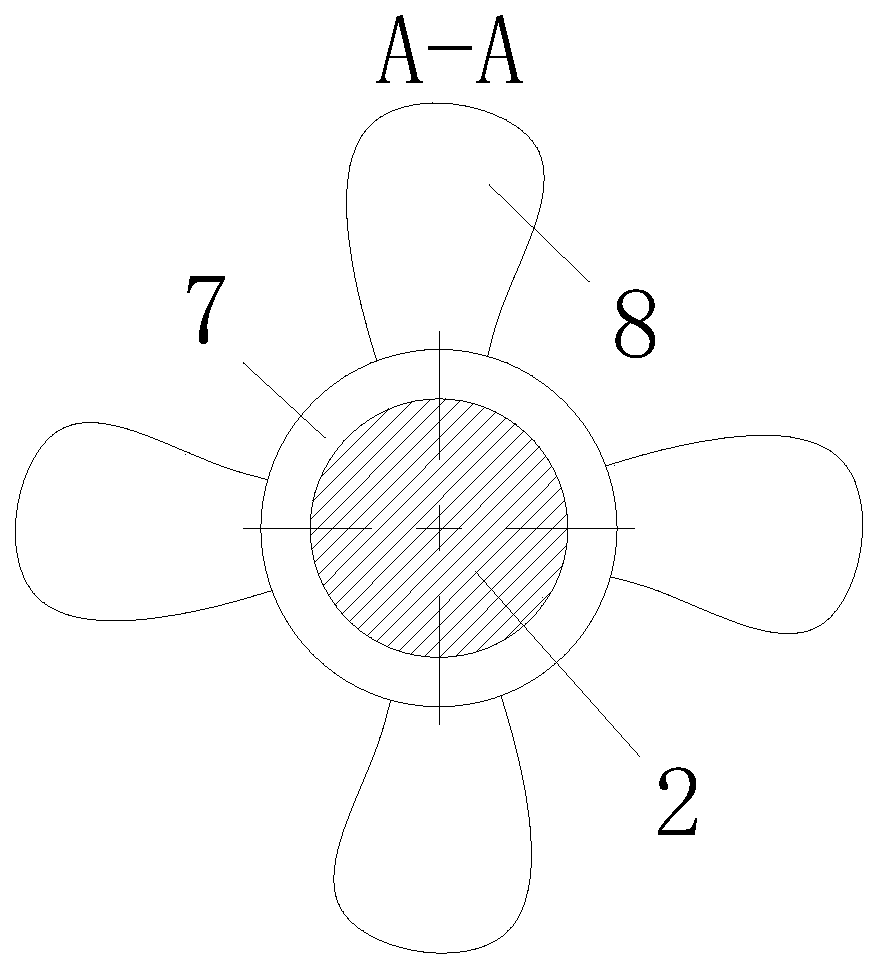

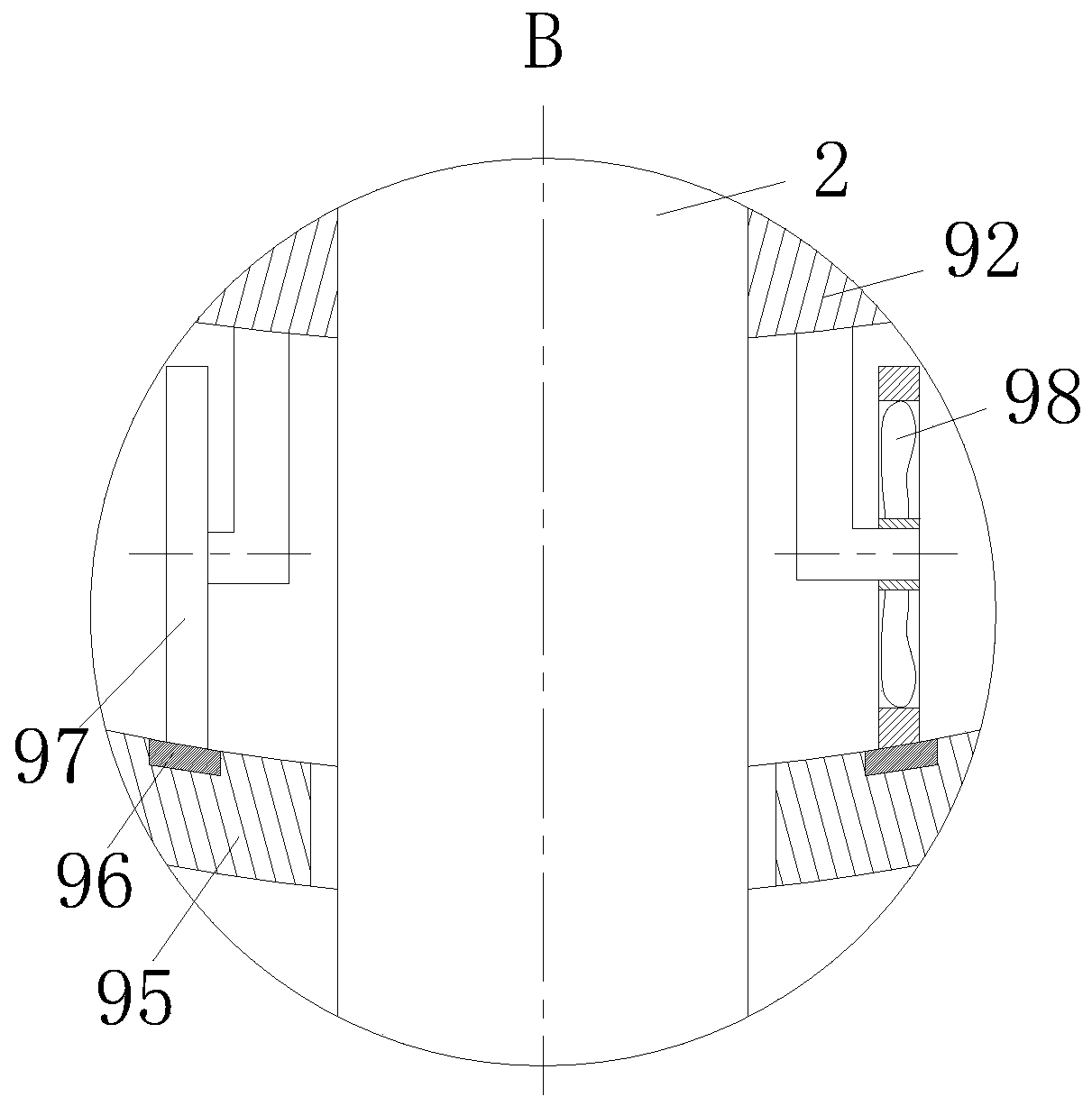

Method used

Image

Examples

Embodiment approach

[0025] As a specific embodiment of the present invention, the protrusions of the No. 1 folding plate 56 close to the housing 1 are semicircular in design, and iron rods 13 are engaged in the protrusions; the iron rods 13 are circular in design, And perpendicular to the No. 1 folding plate 56 is set; the two side walls of the housing 1 are provided with magnet rods 14; the magnet rods 14 are set close to the second chute 55; Both are fixedly connected with a heating frame 15; the heating frame 15 is provided with two heating wires 16; the heating wires 16 are respectively electrically connected to the iron rod 13; the through hole 11 is connected to the heating frame 15; In the process that block 52 drives push plate 54 to move, push plate 54 drives No. 1 folding plate 56 to swing, and the setting of iron rod 13 effectively prevents No. While swinging, the iron rod 13 is moved up and down to cut the magnetic induction line generated by the magnet rod 14, thereby continuously su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com