Stirrer

The technology of agitator and agitator shaft is applied in the directions of mixer accessories, mixers with rotating mixing devices, chemical instruments and methods, etc. Experience, good cooling effect and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

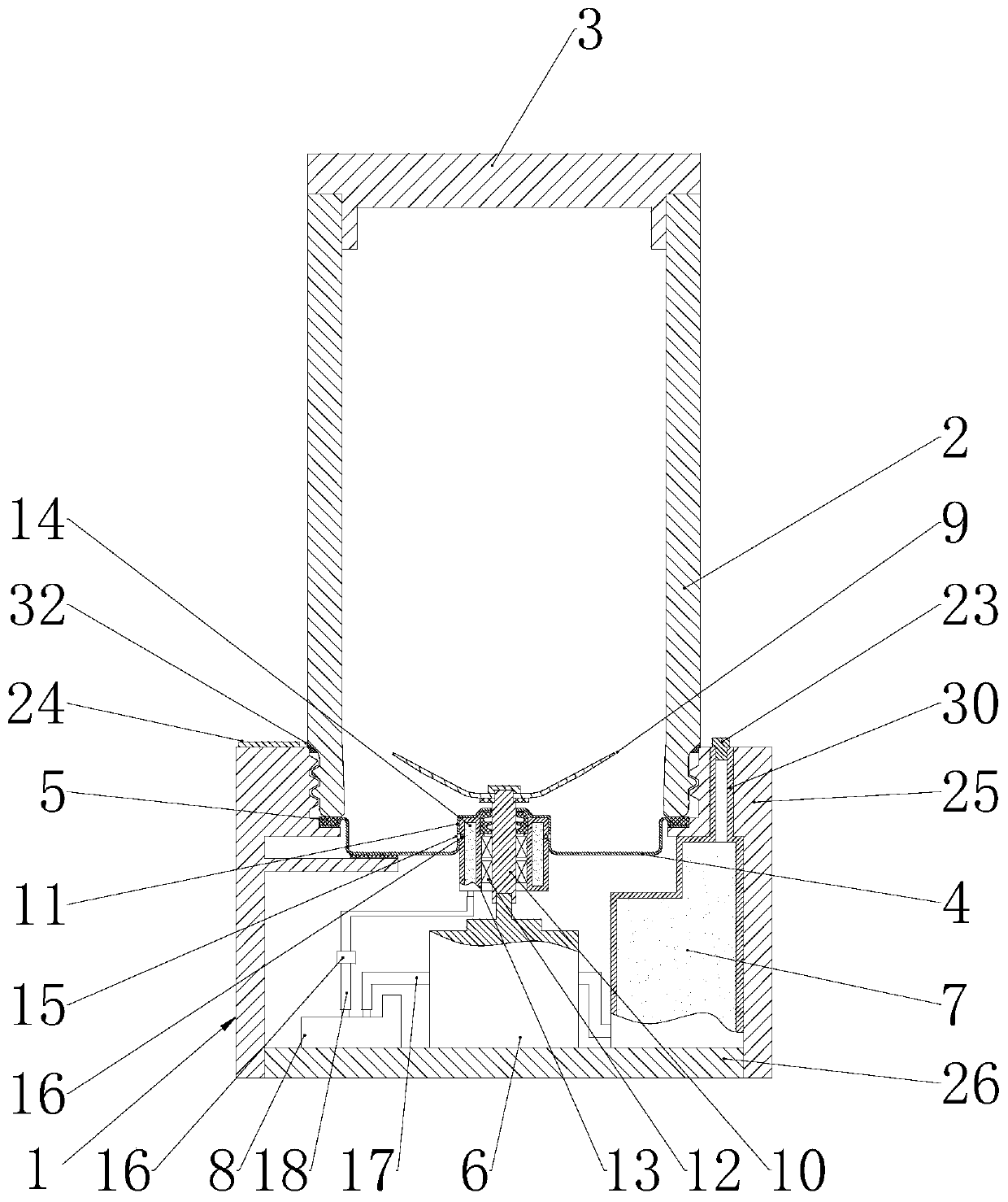

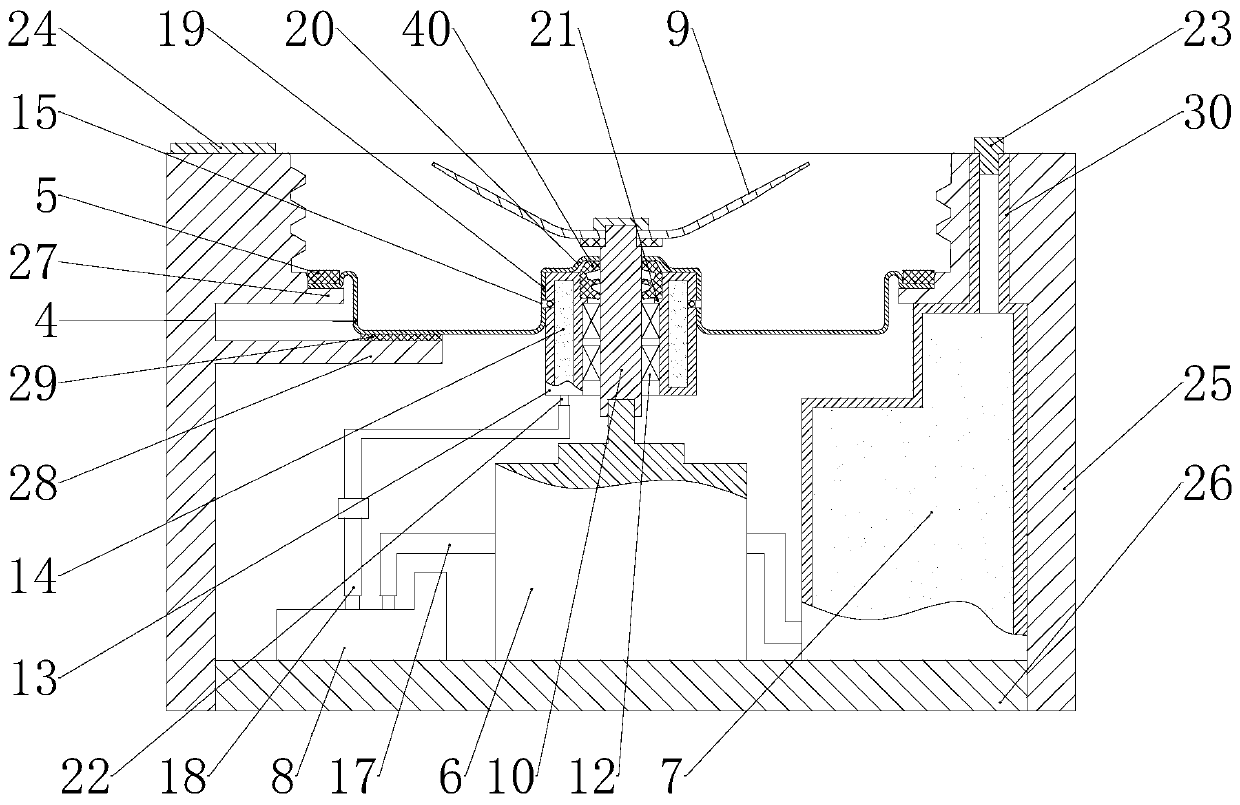

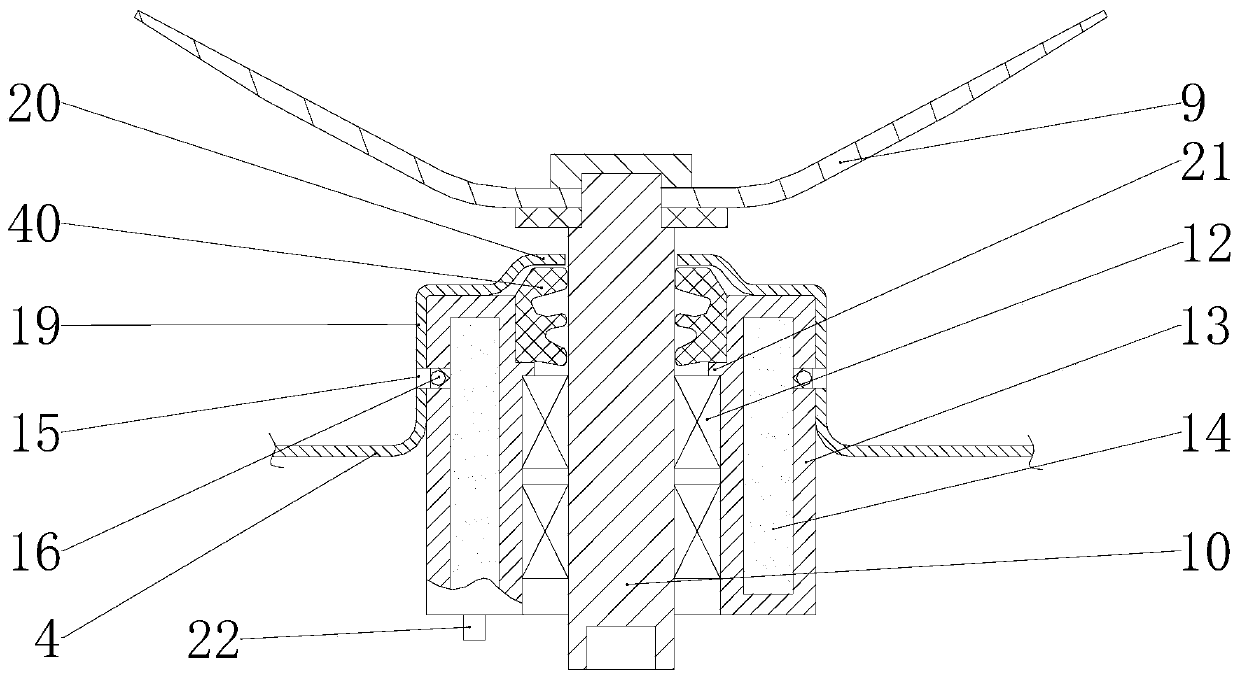

[0022] Embodiment 1: The structure of a stirrer of this embodiment is as follows Figure 1 to Figure 3 Shown includes a container base 1 and a container 2, the container 2 is screwed on the container base 1, the container 2 is a glass container, the container 2 has an upper opening and a lower opening, the upper opening is provided with a container cover 3, and the lower opening is threaded with the container base 1 Connection, the lower opening is provided with a container bottom 4, a sealing gasket 5 is provided between the lower opening and the container bottom 4, and the sealing gasket 5 is squeezed on the container bottom 4 when the lower opening is screwed on the container base 4, and the container base 1 is provided with The motor 6, the water tank 7 and the water pump 8, the top of the container bottom 4 is provided with a stirring knife 9, the stirring knife 9 is a sharp-edged knife, the stirring knife 9 is connected with a stirring shaft 10, the container bottom 4 is ...

Embodiment 2

[0025] Example 2: as Figure 4 As shown, the water tank 7 can also be detachably arranged in the container base 1, and the container base 1 is provided with a water tank cavity 31 for accommodating the water tank 7, and the water tank 7 is provided in the water tank cavity 31 in a drawable manner, so that the water injection plug 23 is not required. , the structure is simpler.

[0026] In the mixer of the present invention, a water tank and a water pump are arranged in the container base. The water pump is connected with a water suction pipe and a water inlet pipe. There is a water inlet hole connected with the annular cavity, and a one-way valve is arranged between the water inlet hole and the annular cavity, so that by controlling the opening of the water pump, even in the process of the agitator working, water can be automatically added to the container, intelligent Good, and there is a one-way valve on the water inlet pipe, and the bearing of the stirring shaft is set clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com