Stator for rotating electrical machine

A technology for rotating motors and stators, which is applied in the manufacture of stator/rotor bodies, electric components, electromechanical devices, etc. It can solve the problems of reduced efficiency of rotating motors and coil reduction, so as to ensure the space factor, prevent sagging, and achieve high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

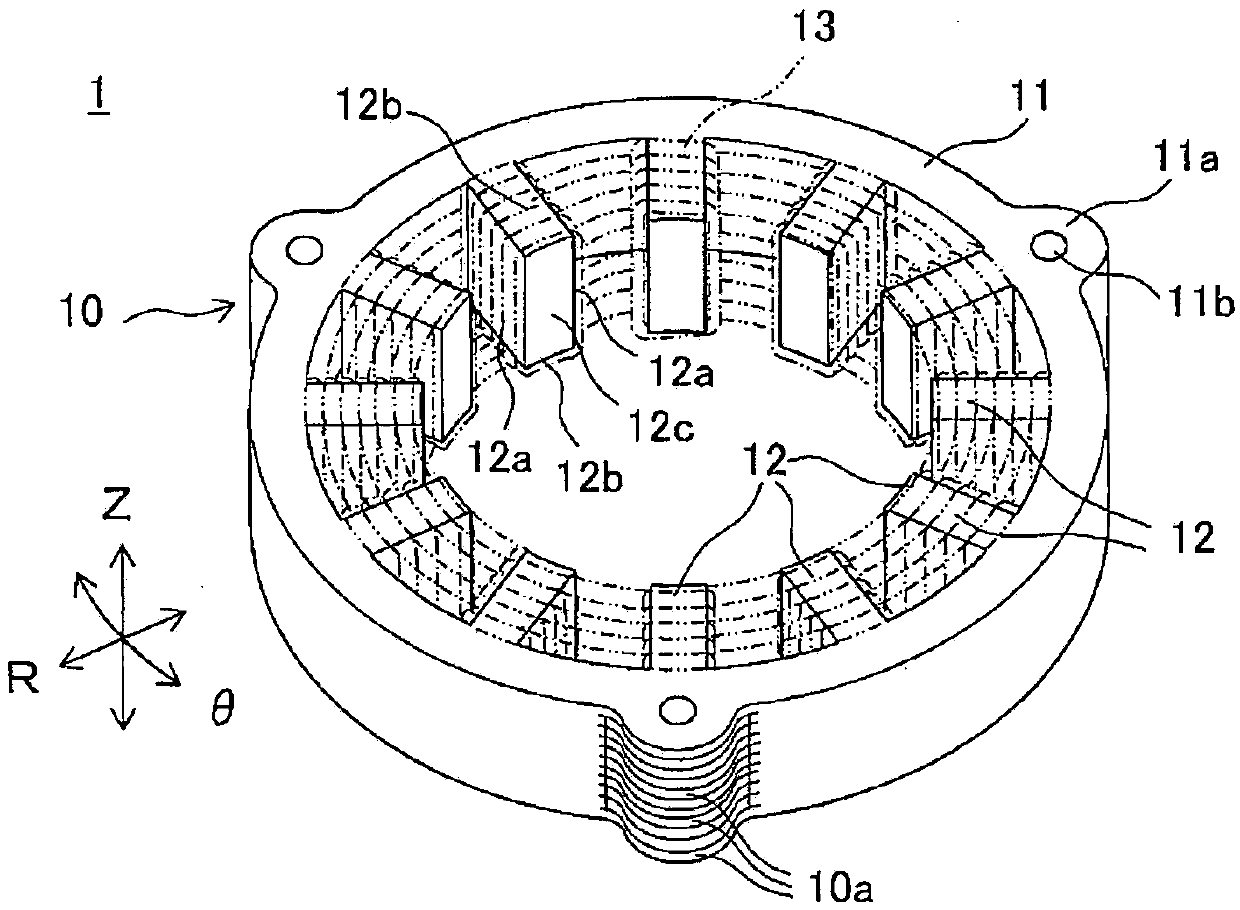

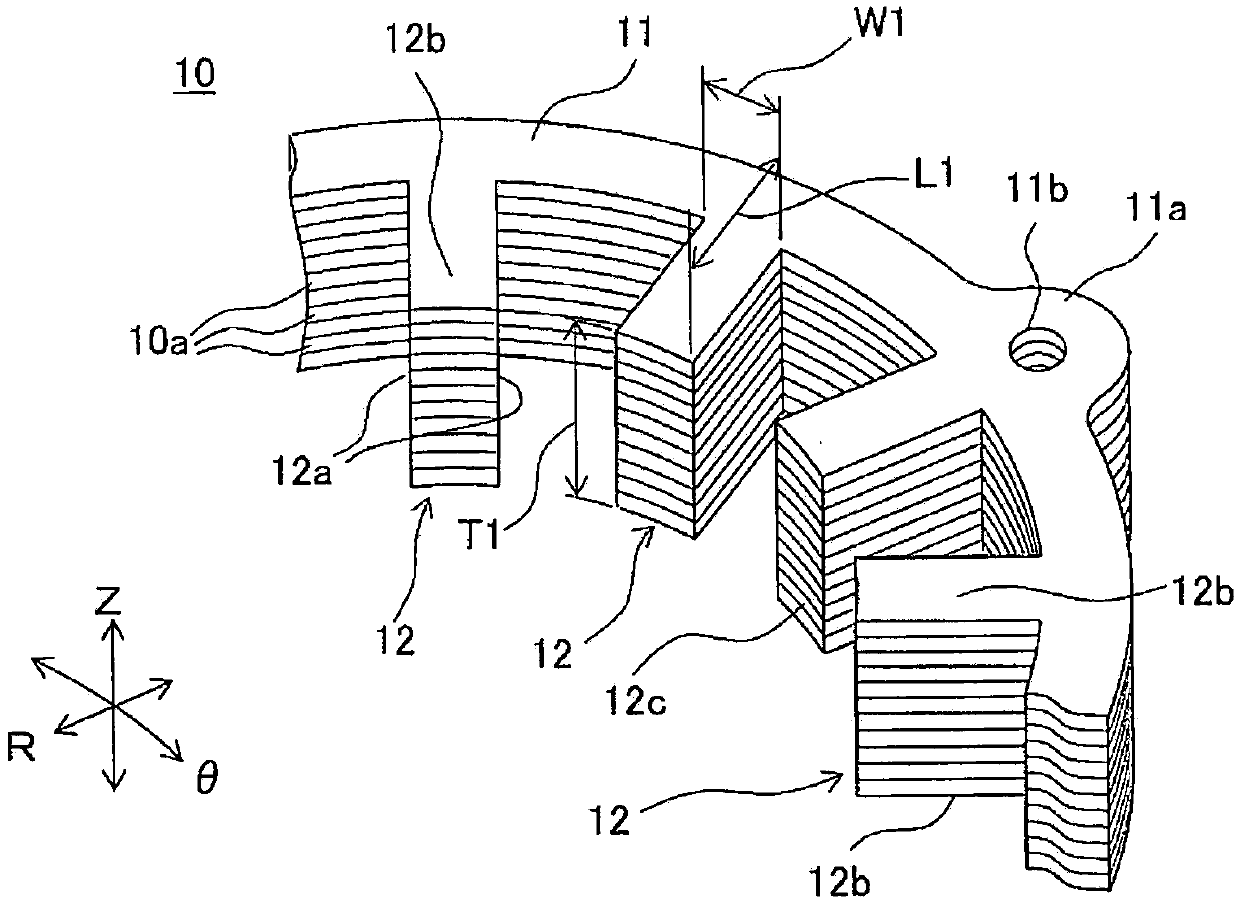

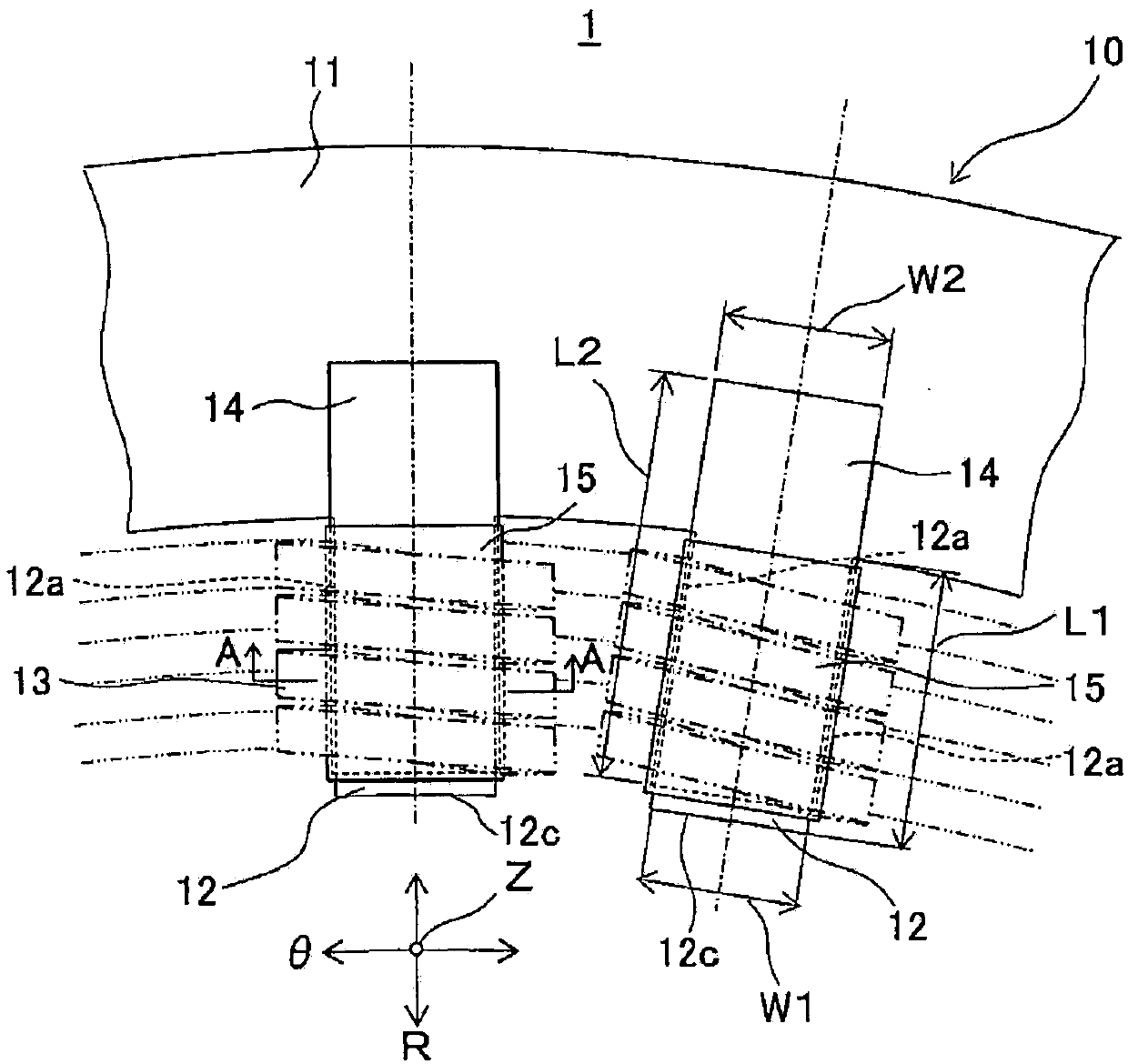

[0063] make out figure 1 A stator for a rotating electric machine is shown. Specifically, 800 foils made of a soft magnetic material (such as an Fe-based alloy with an Fe content of 80% or more produced by a liquid quenching method) with a thickness of 0.025 mm are laminated to form a laminate. A pair of reinforcing members made of an insulating material (unsaturated polyester resin) sandwich each tooth portion of the stator core as a laminated body with respect to the laminated body. In this state, a fixing member made of a tubular insulating material (polyvinyl chloride) fixes a pair of reinforcing members to each tooth portion so as to surround each tooth portion together with a pair of reinforcing members. Next, the conductive wire on which the insulating coating was formed was wound around the stator core in a distributed winding (wave winding) manner to form a coil, thereby producing a stator for a rotating electric machine.

Embodiment 2

[0071] When a model corresponding to the stator of Example 1 was produced and mounted on a motor, analysis software (JMAG-Designer) was used to analyze the loss of the motor when the rotational speed of the motor was 9000 rpm. exist Figure 11 The results are shown in . exist Figure 11 In , the loss of the motor of Example 2 is set to 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap