Coil member, motor and manufacturing method for coil member

A technology for coil components and motors, which is applied in coil manufacturing, coil manufacturing, and motor generator manufacturing, etc., can solve problems such as interference with the barrel 207 and damage to the winding pressure of the coil components, so as to prevent wire breakage and damage, improve Design freedom and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

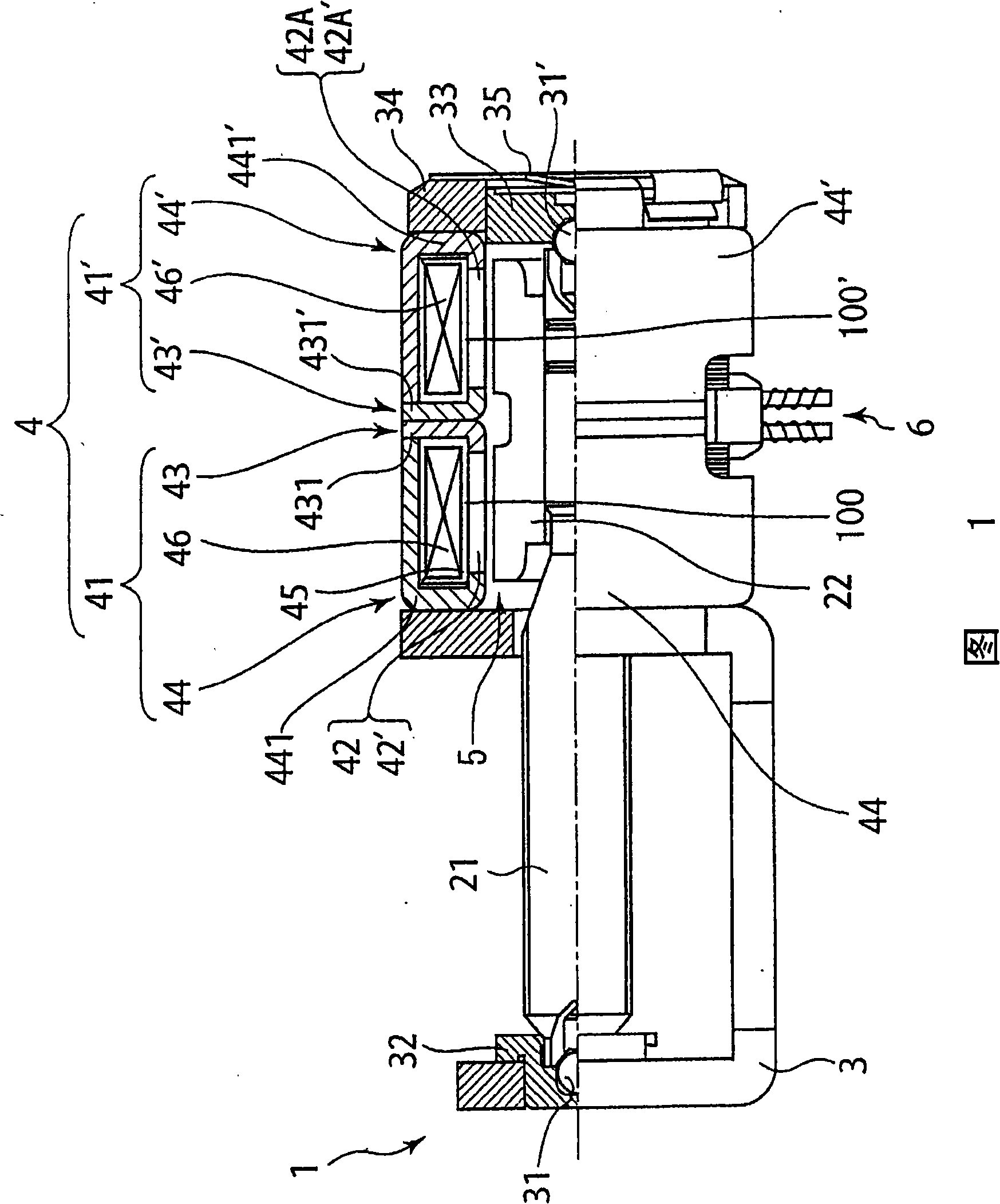

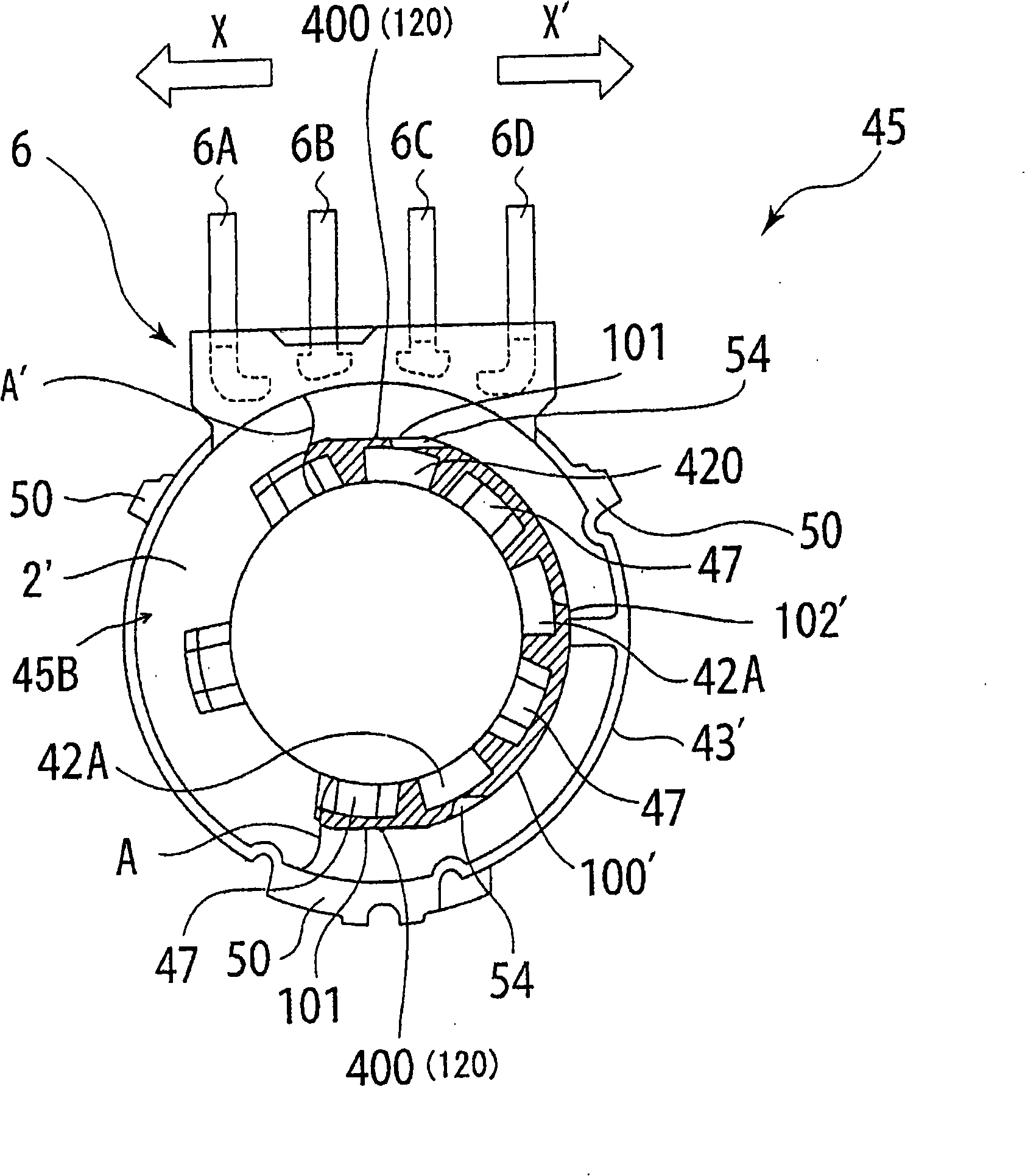

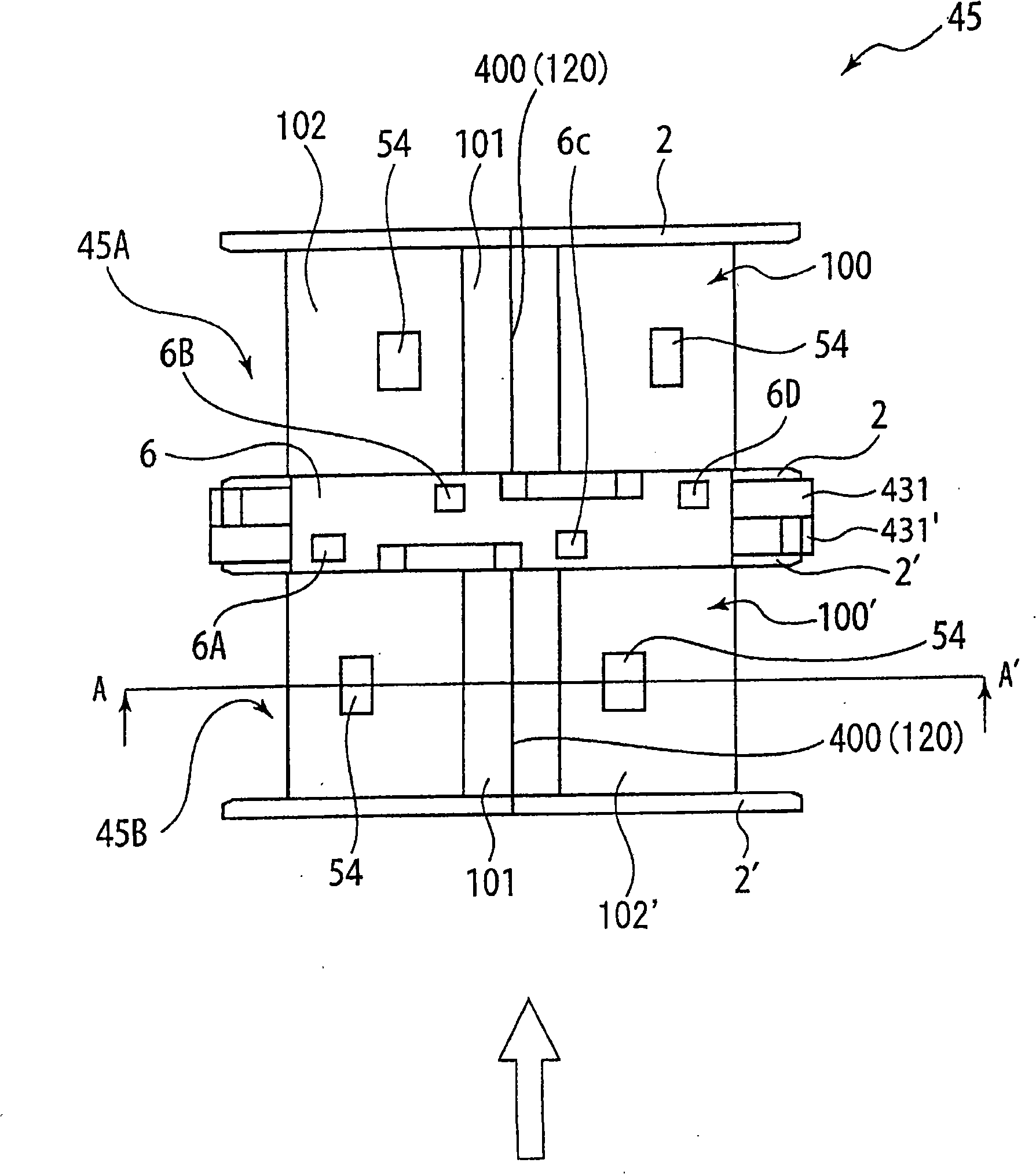

[0062] Hereinafter, a motor according to an embodiment of the present invention will be described with reference to the drawings.

[0063] FIG. 1 is a half cross-sectional view showing an example of a motor according to an embodiment of the present invention, and an overall motor. figure 2 is to indicate that the coil part is in image 3 Partial cross-sectional view seen from the direction of the arrow with a part cut between A-A' shown. image 3 is a side view of a coil component of the motor shown in FIG. 1 . Figure 4 It is a cross-sectional view schematically showing the cylindrical portion of the coil component in a state where the slide mold is closed. Figure 5 is a cross-sectional view schematically showing a state where the inner yoke is held by the slide die and the upper die is opened. Image 6 It is a top view schematically showing the state in which the slide mold is opened. Figure 7 is enlarged Figure 4 An enlarged view of a portion around the parallel pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com