A kind of extraction method and application of medlar glycoprotein

A technology of green scale fish and glycoprotein, applied in the field of biochemistry, to achieve the effect of stable structure, high product extraction rate and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for extracting medlar glycoprotein, comprising the following steps:

[0036] ①Pretreatment: Clean the scales of the fresh medlar, drain the water, cut the fish meat into pieces, and grind them in a meat grinder to obtain the medlar puree, which is weighed;

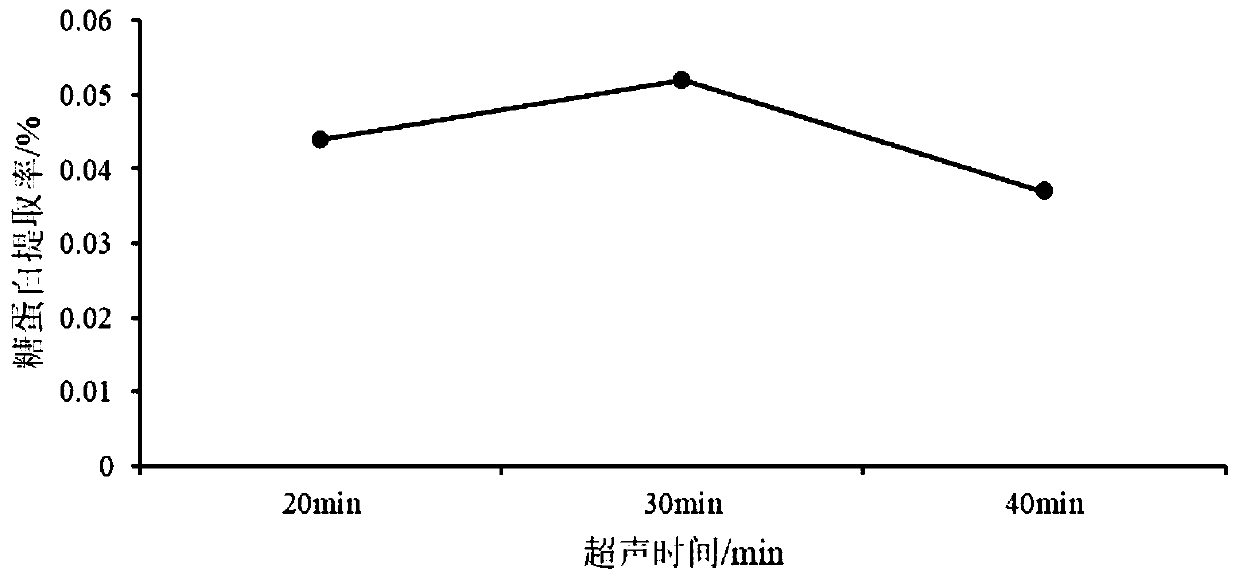

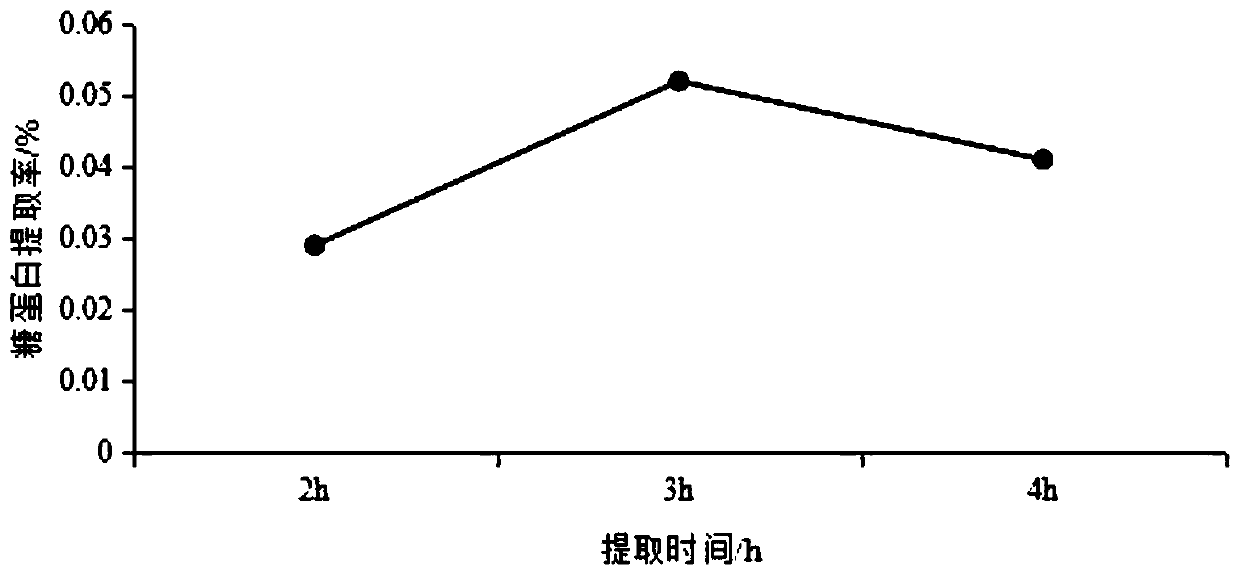

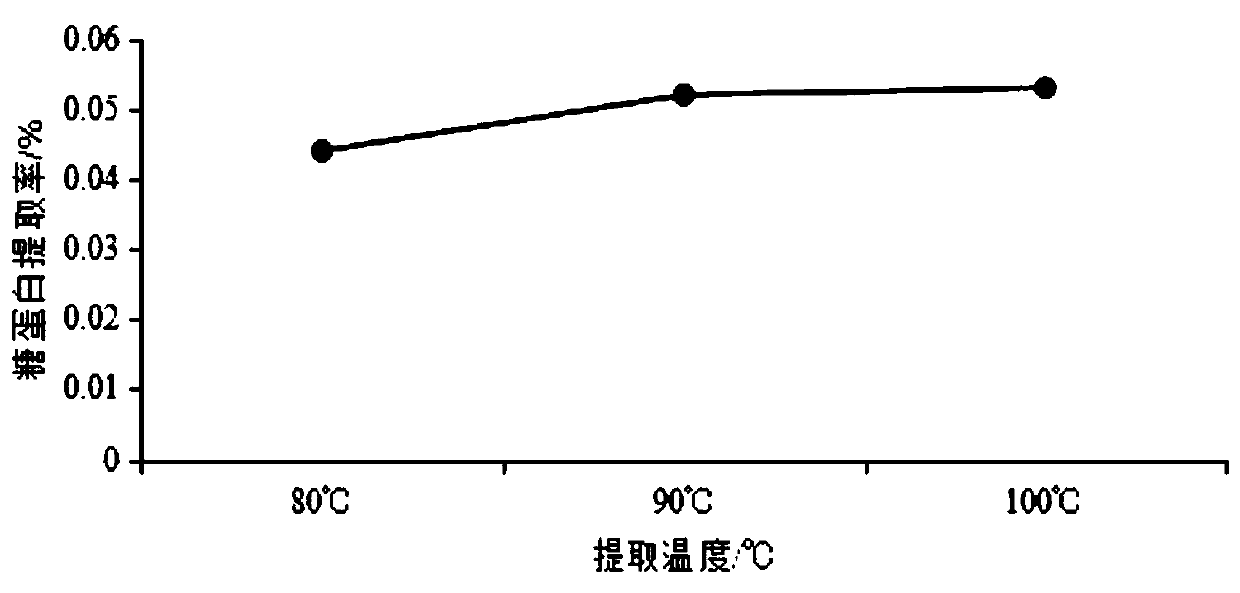

[0037] ②Ultrasonic treatment + hot water leaching: Mix the medlar meat paste obtained in step ① with distilled water at a material-to-liquid ratio of 1:20 (g / mL), and perform ultrasonic treatment for 30 minutes to obtain the medlar mixture and put it in a water bath. Extract in hot water at 100°C for 3 hours, filter, and use the obtained filtrate for later use. Mix the obtained filter residue with distilled water at a solid-liquid ratio of 1:20 (g / mL) and ultrasonically treat it for 30 minutes, then extract in hot water at 100°C for 1 hour, and filter , combining the filtrates twice to obtain the medlar glycoprotein mixed solution;

[0038] ③ Concentrated alcohol precipitation: Add the mixed solution obtai...

Embodiment 2

[0044] The operation steps of embodiment 2 and embodiment 1 are basically the same, and its difference is:

[0045] In the step ② ultrasonic treatment + hot water leaching: mix the medlar meat paste obtained in step ① with distilled water at a material-to-liquid ratio of 1:30 (g / mL), and ultrasonically treat it at 25°C for 40 minutes to obtain the medlar The mixture was placed in a water bath, leached with hot water at 90°C for 2 hours, filtered, and the obtained filtrate was used for later use. The obtained filter residue was mixed with distilled water at a material-liquid ratio of 1:30 (g / mL), then ultrasonically treated for 40 minutes, and then heated at 90°C Water leaching for 1 hour, filtering, and combining the two filtrates to obtain a medlar glycoprotein mixed solution;

[0046] Step ③ concentrated alcohol precipitation: put the mixed solution obtained in step ② into a rotary evaporator, evaporate and concentrate at 60°C to 1 / 5 of the original volume, add 3 times the v...

Embodiment 3

[0049] The operation steps of embodiment 3 and embodiment 1 are basically the same, and its difference is:

[0050] In the step ② ultrasonic treatment + hot water leaching: mix the medlar meat paste obtained in step ① with distilled water at a material-to-liquid ratio of 1:40 (g / mL), and ultrasonically treat it for 20 minutes at 30°C to obtain the medaka The fish mixture was placed in a water bath, leached in hot water at 80°C for 4 hours, filtered, and the obtained filtrate was used for later use. The obtained filter residue was mixed with distilled water at a solid-liquid ratio of 1:40 (g / mL), then ultrasonically treated for 20 minutes, and then heated at 80°C Hot water leaching for 1 hour, filtering, and combining the two filtrates to obtain a mixed solution of medlar glycoprotein;

[0051] Step ③ concentrated alcohol precipitation: put the mixed solution obtained in step ② into a rotary evaporator, evaporate and concentrate at 70°C to 1 / 5 of the original volume, add 3 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com