Separate layer water injection system of small cased well

A technology of layered water injection and cased well, which is applied in the wellbore/well valve device, wellbore/well components, production fluid, etc., which can solve the problem that one-way pressure wave communication cannot obtain real-time flow and formation pressure on the ground.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

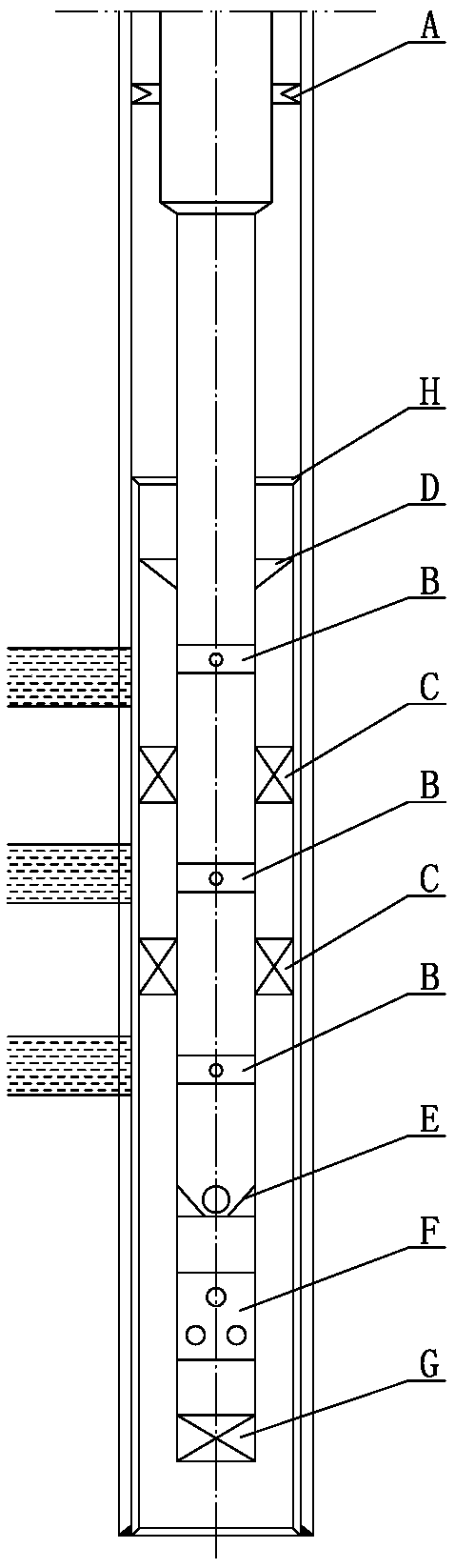

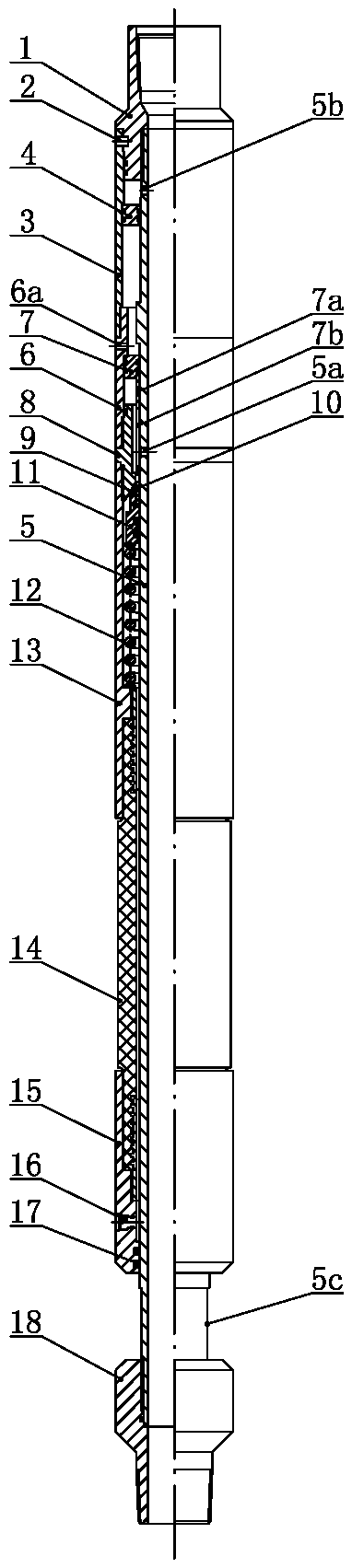

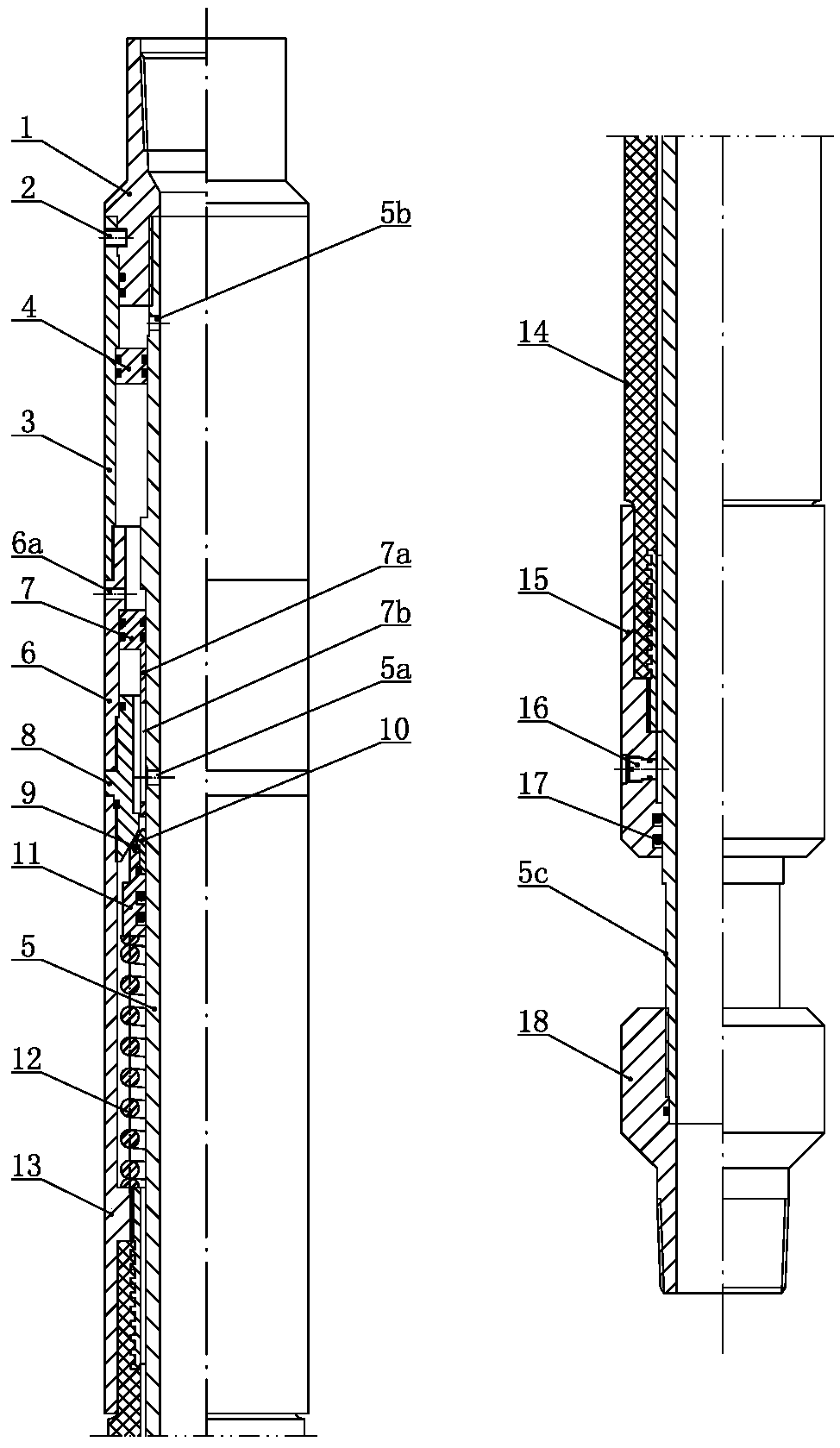

[0029] Such as figure 1 As shown, in the layered water injection system of the small cased well of the present invention, the upper end of the small casing is suspended on the inner wall of the large casing through the casing hanger H, and the inner cavity of the small casing is inserted with a water injection string, and the water injection string The upper end protrudes above the small casing and is connected to the large-diameter section of the pipe string through a variable-diameter joint. The large-diameter section of the pipe string is fixed in the inner cavity of the large casing through a hydraulic anchor A. The corresponding positions on the water injection pipe string and the oil layer are respectively Intelligent water distributors B are installed, and each intelligent water distributor B is controlled by the ground control system. Packers C are installed between adjacent intelligent water distributors, and centralizers D are installed above the top intelligent water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com