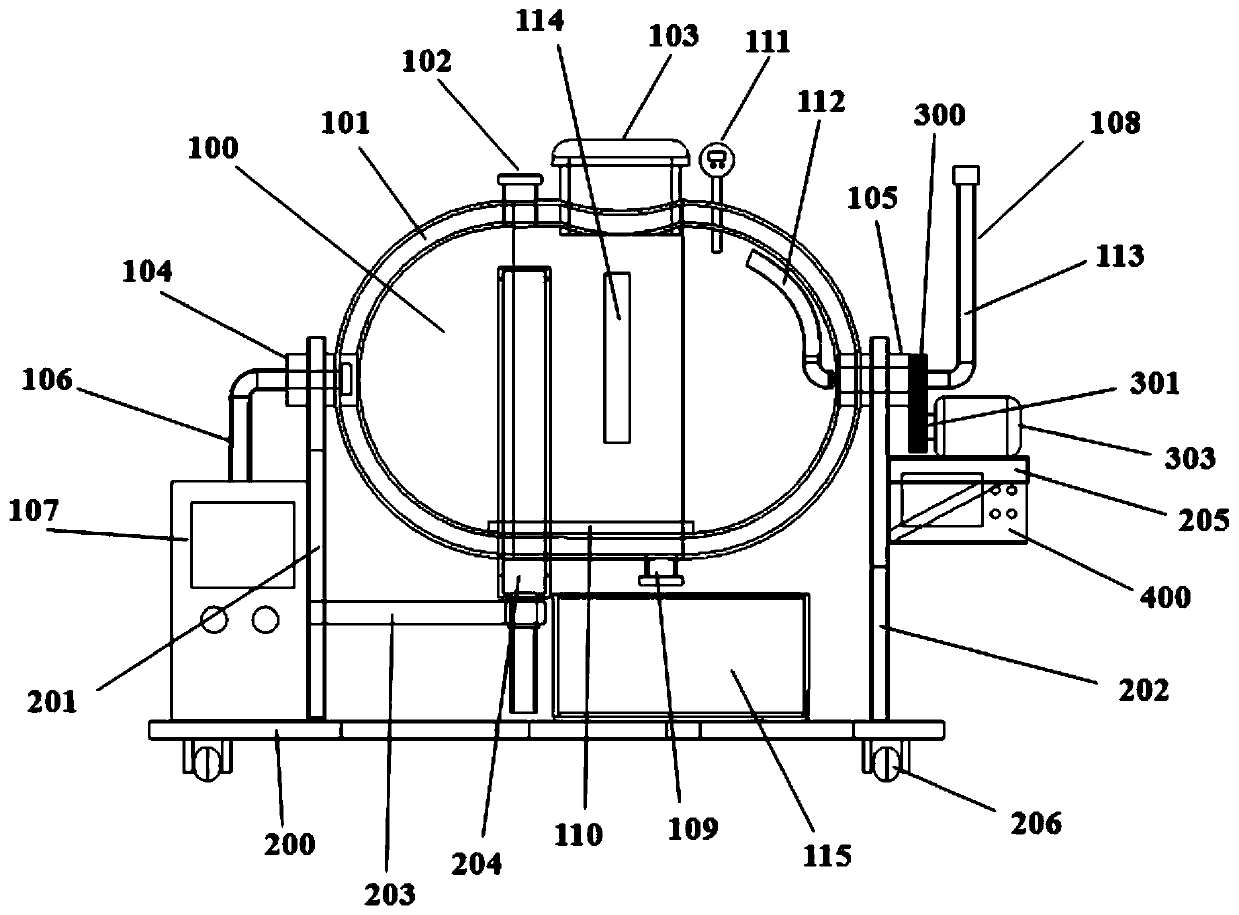

Sauced product halogenated processing equipment and method thereof

A processing equipment and product technology, applied in the direction of food science, etc., can solve the problems of brine temperature, inaccurate and controllable time, industrialization, low degree of automation, uneven heating of brine pots, etc., to achieve automatic and efficient production and avoid harmful substances High content, the effect of preventing excessive cooking of stewed soup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] Step 1. Pre-cooking: Cut the raw beef into pieces and wash them. Each piece weighs 400g. Put it into the marinating tank through the feeding port, and pour clean water through the water supply and drainage port of the marinating tank to submerge the raw beef. Heat the marinating tank and rotate it. For the tank body, start precooking. When the temperature in the tank reaches 80°C, froth appears. Stop the rotation. Tilt the stewed tank so that the liquid level in the stewed tank is equal to the water supply and drainage port of the stewed tank. Froth, continue to heat until boiling and keep for 3 minutes, turn over the marinated tank to drain the pre-boiled water from the water supply and drain outlet, and drain the water;

[0057] Step 2. Prepare the marinade: crush the stewed ingredients into 20-mesh fine materials and mix well, crush the onion and ginger into powder and reserve the juice, mix the two and add soy sauce and cooking wine and mix well to obtain the marinad...

example 2

[0062] Step 1. Precooking: Cut the raw beef into pieces and wash them, each weighing 500g, put them into the marinated tank through the feeding port, and pour clean water through the water supply and drainage port of the marinated tank to submerge the raw beef, heat the marinated tank and rotate For the tank body, start precooking. When the temperature in the tank reaches 80°C, froth appears. Stop the rotation. Tilt the stewed tank so that the liquid level in the stewed tank is equal to the water supply and drainage port of the stewed tank. Froth, continue to heat until boiling and keep for 3 minutes, turn over the marinated tank to drain the pre-boiled water from the water supply and drain outlet, and drain the water;

[0063] Step 2. Prepare the marinade: crush the stewed ingredients into 30-mesh fine materials and mix well, crush the onion and ginger into fine powder and reserve the juice, mix the two and add soy sauce and cooking wine and mix well to obtain the marinade. Th...

example 3

[0068] Step 1. Pre-cooking: Cut the raw rib meat into pieces and wash, each weighing 450g, put it into the marinated tank through the feeding port, and pour clean water through the water supply and drainage port of the marinated tank to cover the raw rib rib meat, and heat Stew the tank and rotate the tank to start precooking. When the temperature in the tank reaches 80°C, froth appears, stop the rotation, and tilt the stewed tank so that the liquid level in the stewed tank is equal to the water supply and drainage port of the stewed tank. Cover the tank, skim the froth, continue to heat until boiling for 3 minutes, turn over the marinated tank to drain the pre-boiled water from the water supply and drain outlet, and drain the water;

[0069] Step 2. Prepare the marinade: crush the stewed ingredients into 30-mesh fine materials and mix well, crush the onion and ginger into fine powder and reserve the juice, mix the two and add soy sauce and cooking wine and mix well to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com