Battery barley paper pasting device

A technology of highland barley paper and batteries, which is applied in battery assembly machines, secondary battery manufacturing, sustainable manufacturing/processing, etc. It can solve problems such as limitations, easy to generate severe vibration, and battery stability defects, and achieve good limit protection. , Protect cleanliness, improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

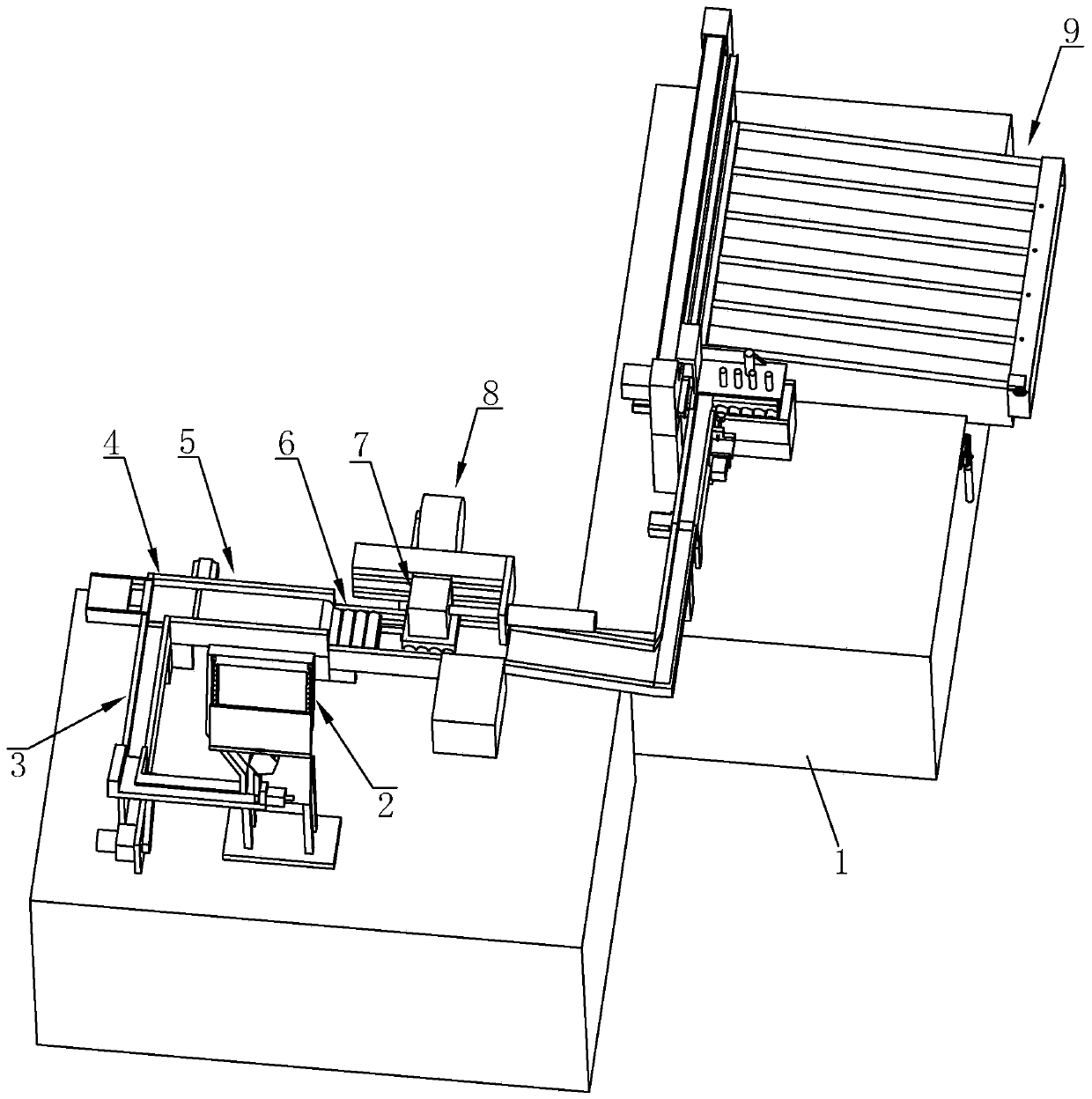

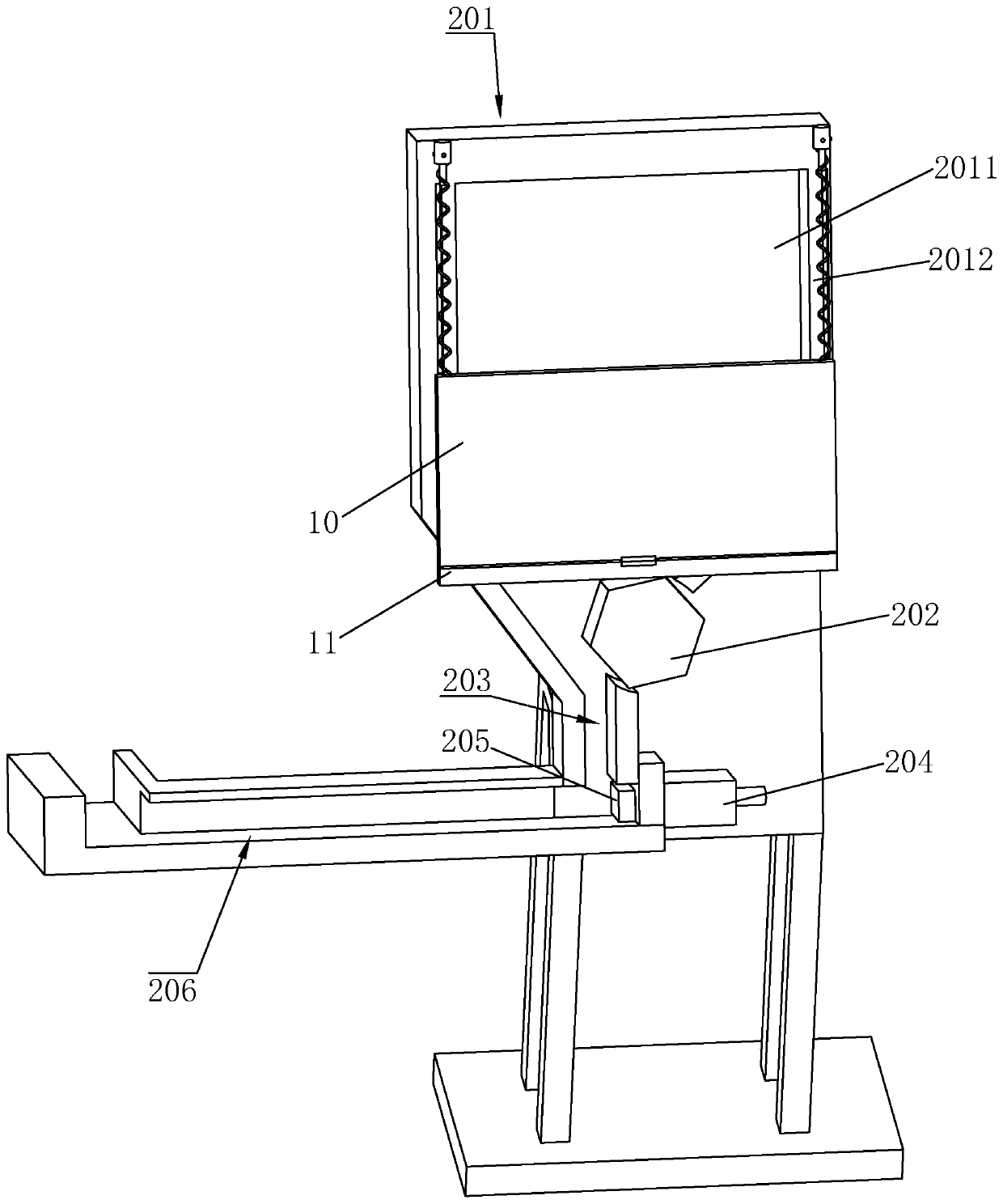

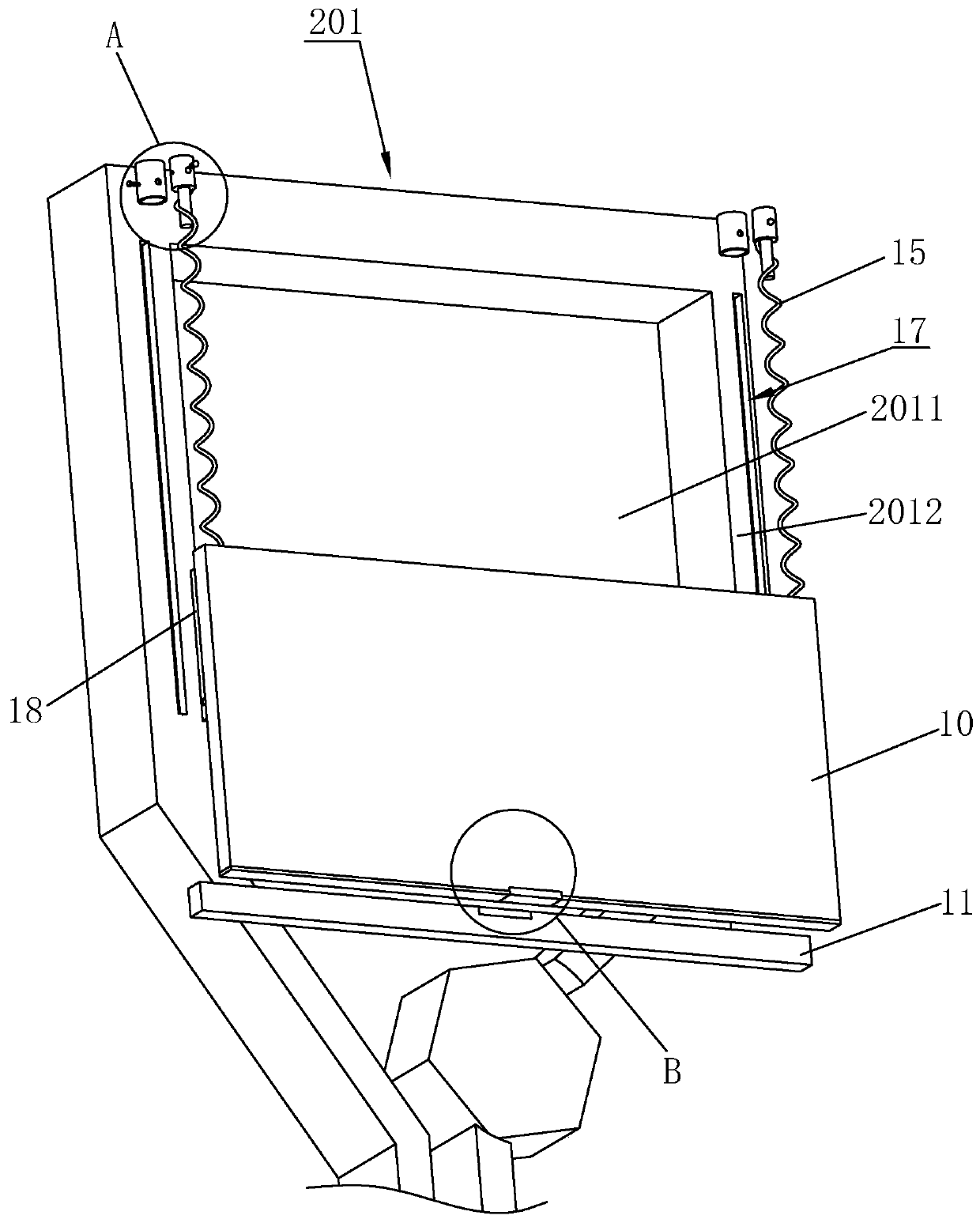

[0042] A battery paste barley paper device, refer to figure 1 , including the frame (not marked in the figure) and the installation platform 1 installed on the frame, the material storage mechanism 2 arranged on the installation platform 1, the first material delivery mechanism 3, the testing mechanism 4, and the second material delivery mechanism 5 , a material shifting mechanism 6, a material handling mechanism 7, a barley paper sticking mechanism 8 and a finished product sorting and recycling mechanism 9, the storage mechanism 2 is provided with a battery flow path 206, and the battery flow path 206 is connected to the feed end of the first material conveying mechanism 3 Connection, the test mechanism 4 is connected between the discharge end of the first material delivery mechanism 3 and the feed end of the second material delivery mechanism 5; the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com