Intermittent film cutting printing equipment and intermittent film cutting method thereof

A printing equipment and technology for printing paper, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of printing paper damage and inconvenience in fixing printing paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

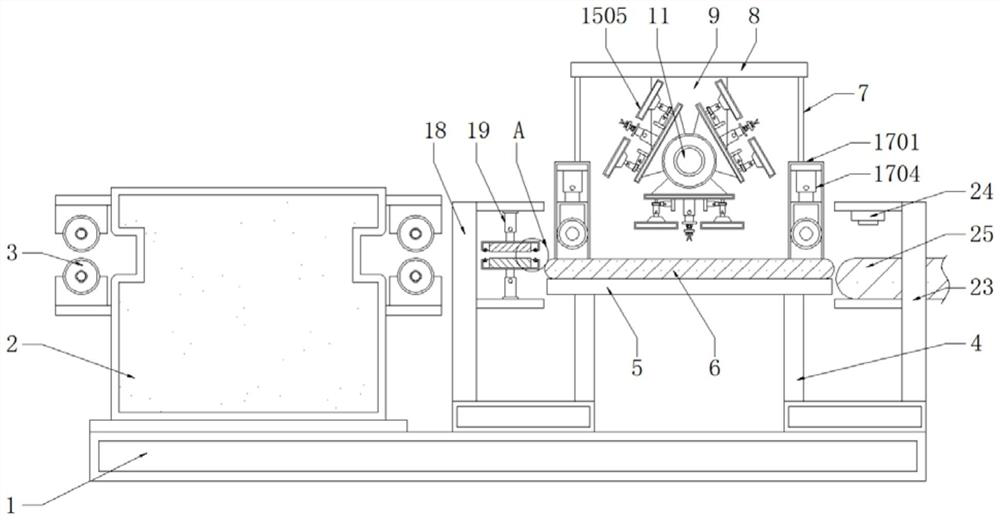

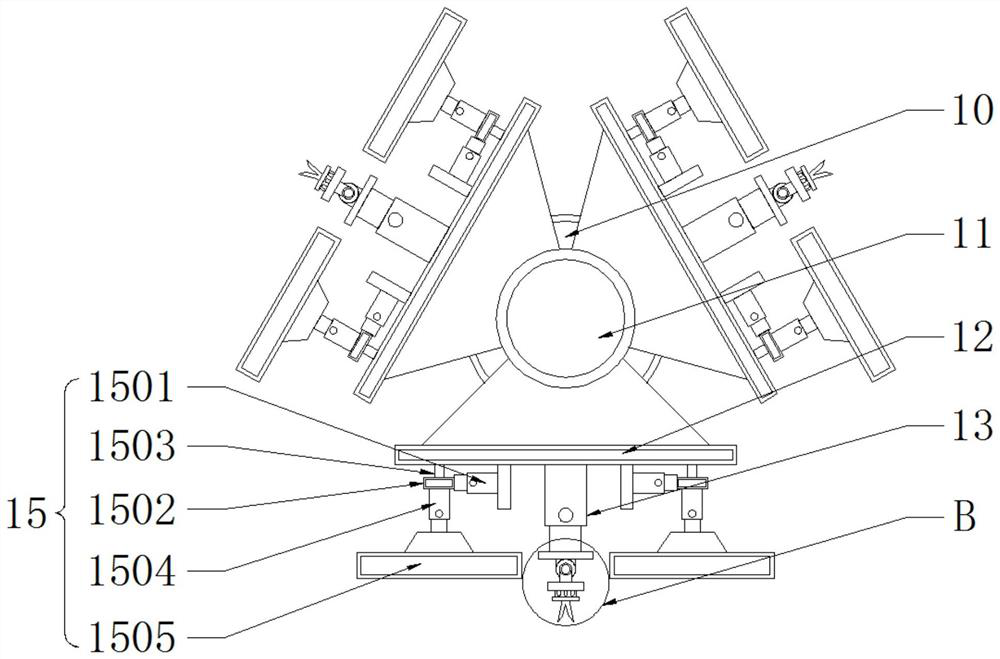

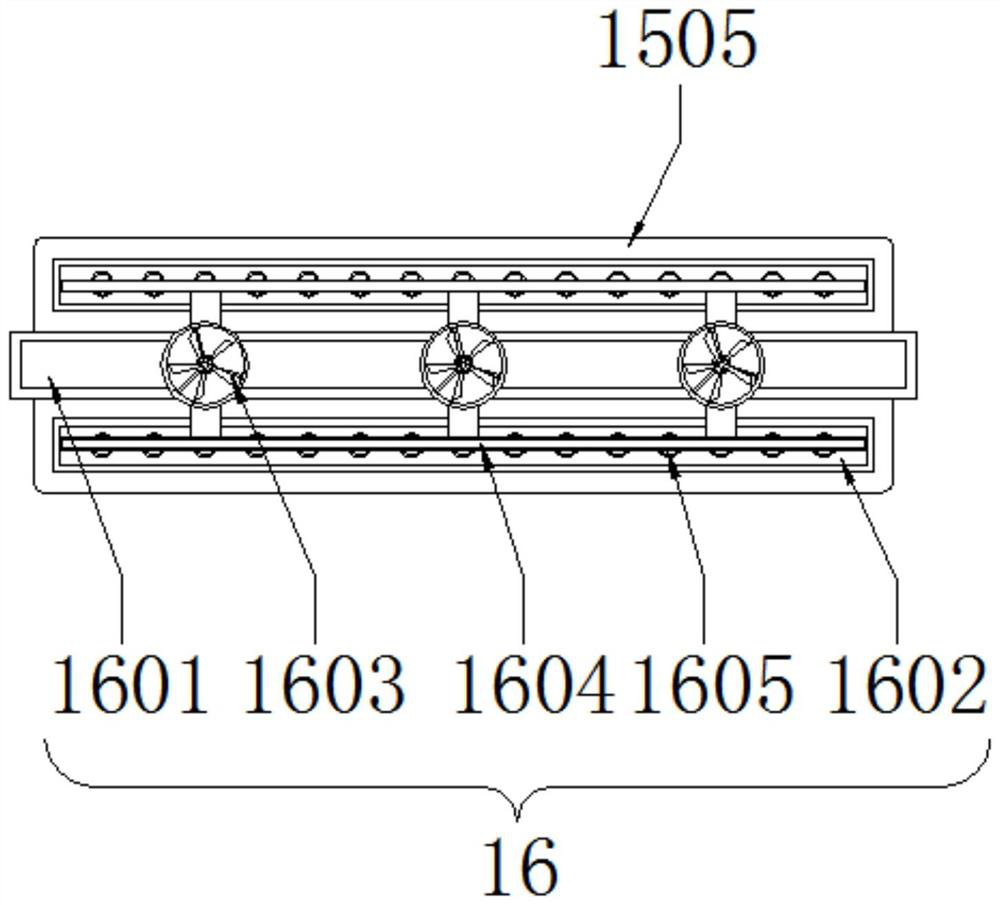

[0035] see Figure 1 to Figure 7 , the present invention provides a technical solution: an intermittent film cutting and printing equipment, including a rotating shaft 11, a die-knife assembly 14 and an adsorption and fixing assembly 16, a fixed outer plate 12 is fixed on the outside of the rotating shaft 11, and the middle of the outer plate 12 is fixed outside. The electric telescopic rod 13 is installed, the die-knife assembly 14 is installed on one end of the electric telescopic rod 13, the outer two sides of the fixed outer plate 12 are installed with an adjustment assembly 15, and the adjustment assembly 15 includes a first push rod 1501, a connecting block 1502, The sliding block 1503, the second push rod 1504 and the adsorption outer frame 1505, the top end of the first push rod 1501 is fixed with a connecting block 1502, and the upper side of the connecting block 1502 is provided with a sliding block 1503, and the lower side of the connecting block 1502 is installed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com