A control method of waste heat recovery system

A waste heat recovery system and control method technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems that the recovered heat is not stable enough, uncontrollable, and unable to perform stable output, etc., to prevent Effects of heat exchange, improved recovery, and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

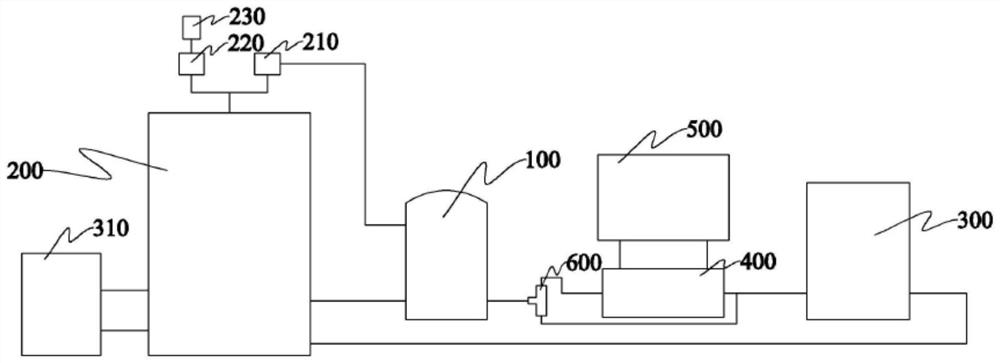

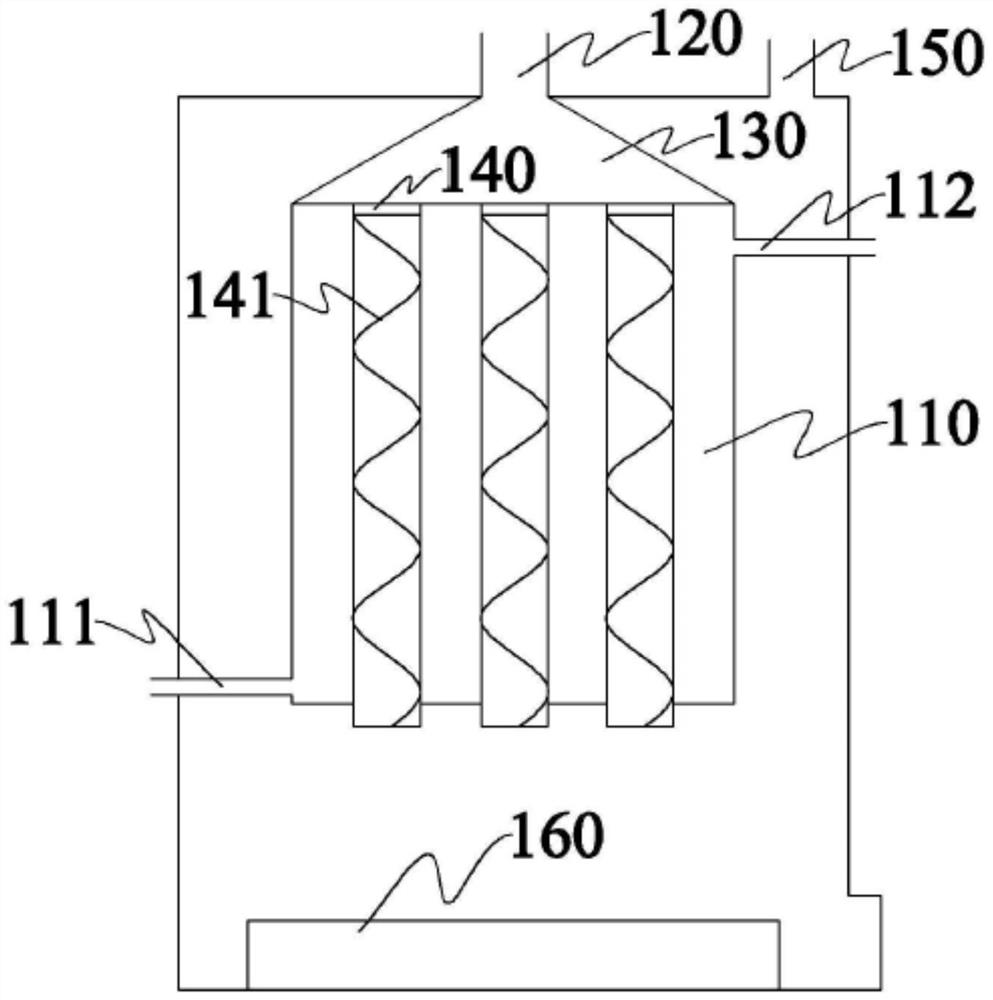

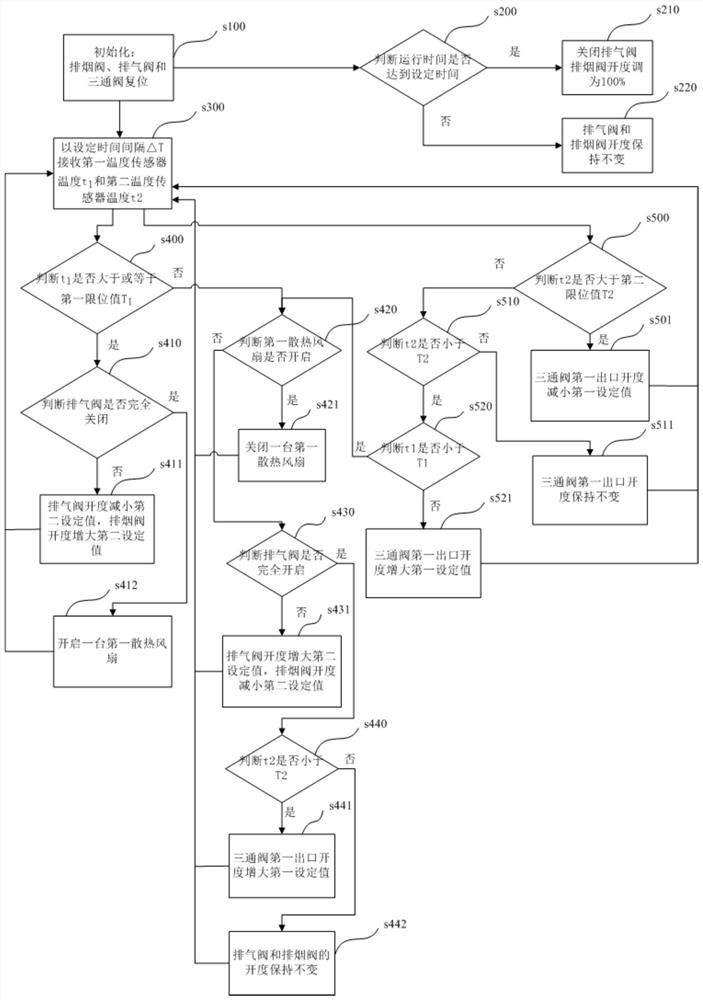

[0035] Please refer to figure 1 , the present embodiment provides a waste heat recovery system, including a generator set 200 and a PLC module; the inside of the generator set 200 is provided with a high-temperature cooling pipeline, and the high-temperature cooling pipeline is connected to an external high-temperature water circulation device; the outlet of the high-temperature cooling pipeline A first temperature sensor is provided; a parallel exhaust valve 210 and a smoke exhaust valve 220 are provided at the exhaust port of the generator set 200, and the exhaust valve 210 is connected to the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com