Assembly process for controlling bearing clearance

A technology of assembly process and bearing clearance, applied in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as complex movements and many processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with accompanying drawing.

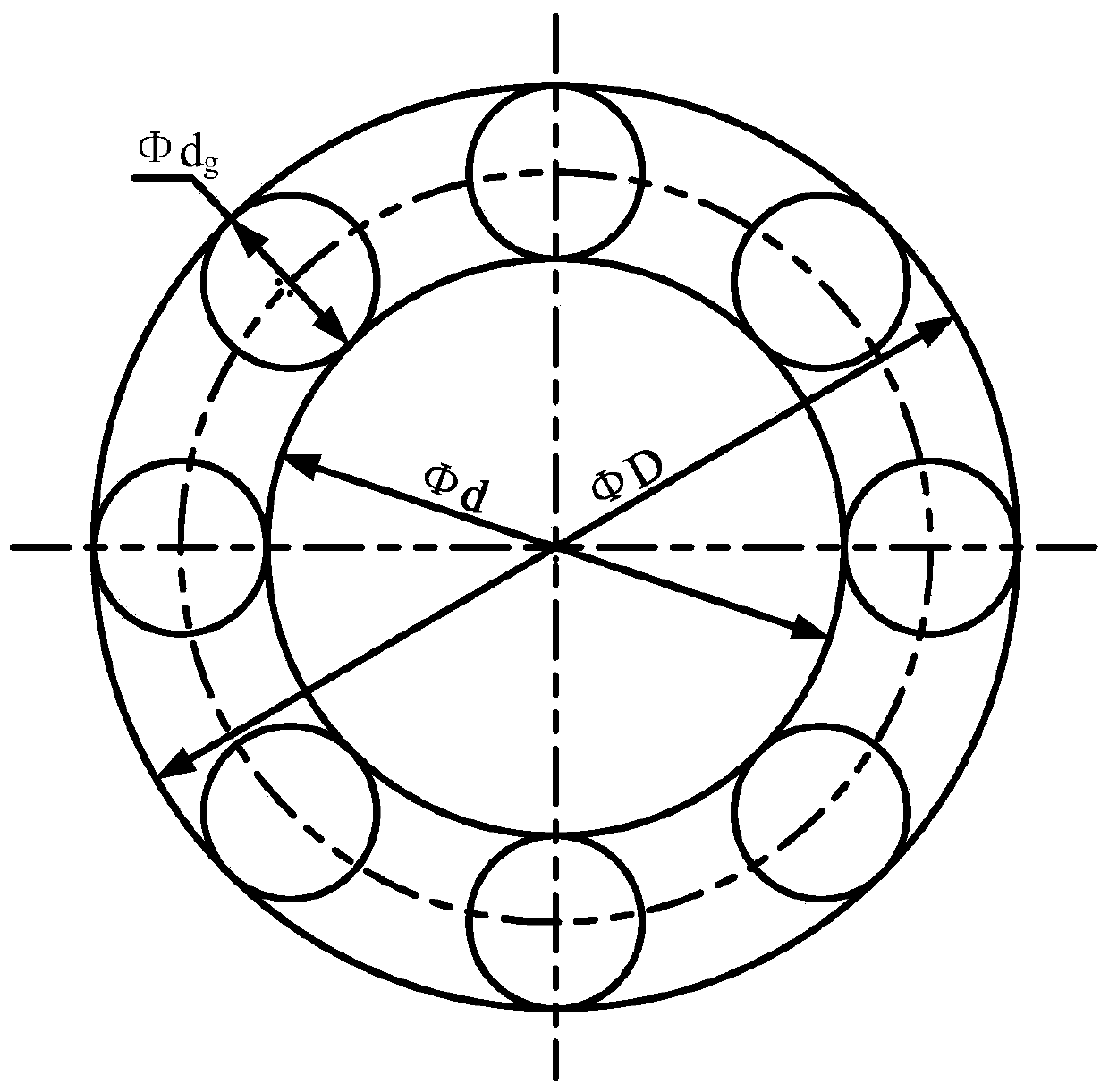

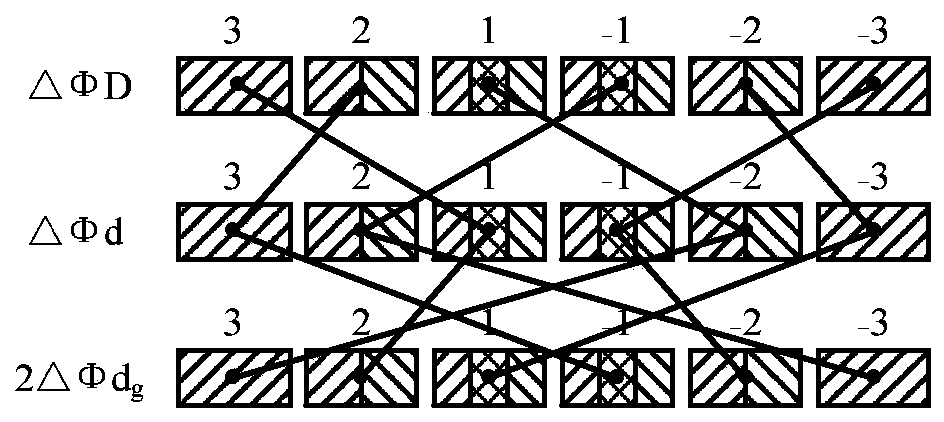

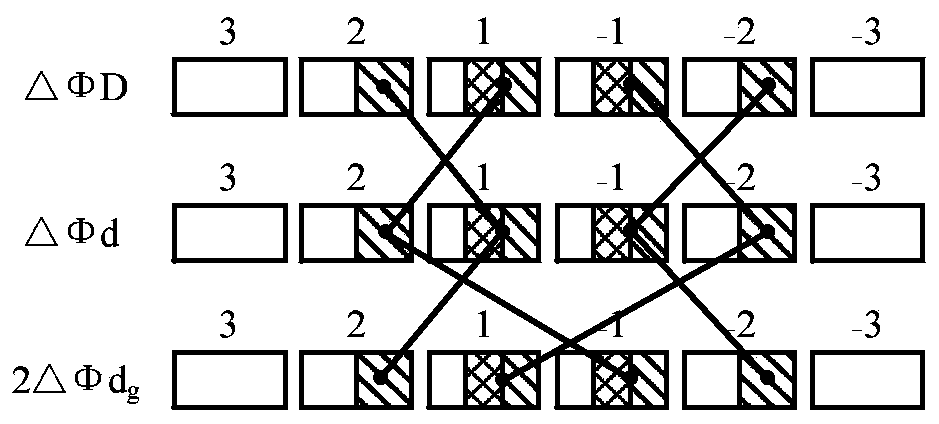

[0076] Such as figure 1 As shown, define the diameter of the outer circle of the inner ring as Φd, the diameter of the inner hole of the outer ring as ΦD, the diameter of the ball as Φdg, the tolerance of the diameter of the outer circle of the inner ring as △d, and the tolerance of the diameter of the inner hole of the outer ring as △D, The diameter tolerance of the ball is △dg, then, the assembly clearance μ 0 =ΔD-Δd-2Δdg. Therefore, selecting the outer ring, inner ring, and balls of △D=△d=2△dg for assembly can achieve the highest assembly accuracy at the same cost.

[0077] After measurement, the applicant found that the distribution of the specific errors of the inner ring, outer ring, and balls within the dimensional tolerance range is close to a normal distribution, that is, the number of large tolerances is small, and the number of small tolerances is large; speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com