Pull-type drilling rig derrick base structure

A trailer-type and derrick technology, which is applied to drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of limited use area, many transportation trips, and high transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

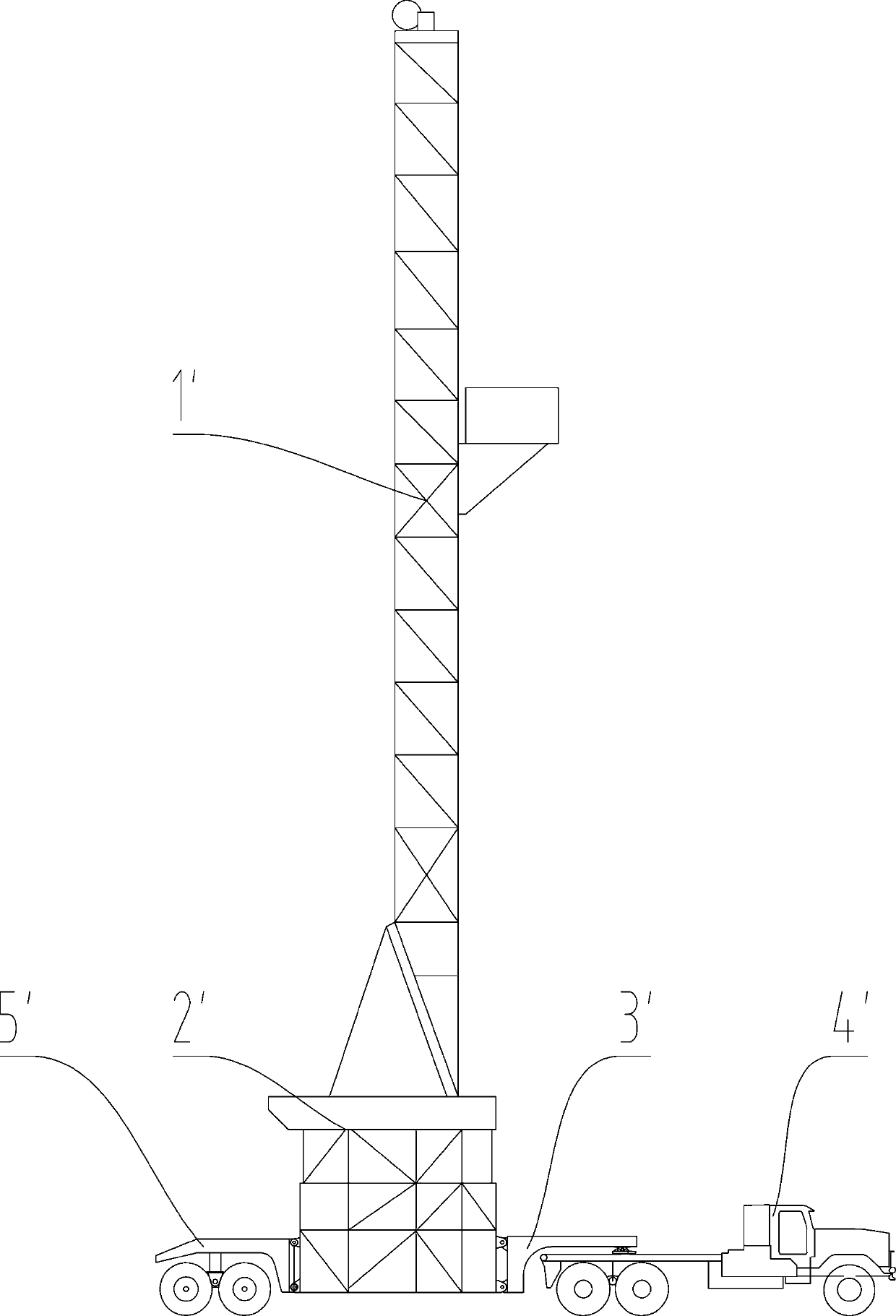

[0115] Such as Figure 8 As shown, the base structure of the trailer-type drilling rig derrick includes a base assembly 2 connected to the foundation, a derrick assembly 1 movably connected with the base assembly 2, and a trailer frame assembly movably connected with the base assembly 2 and the derrick assembly 1 respectively. 3, also includes connecting fasteners 4 that are movably connected with the base assembly 2, the derrick assembly 1 and the trailer frame assembly 3, and the jacking cylinder that is fixedly connected with the trailer frame assembly 3 or the base assembly 2 5. The strut 6 that is movably connected with the connecting fastener 4, and the top of the trailer frame assembly 3 are fixedly equipped with a winch A, a hydraulic station B, a rope reversing machine C and a BOP control device.

[0116] In this embodiment, the number of jacking cylinders 5 is six, of which four jacking cylinders 5 are evenly and symmetrically distributed on both sides of the trailer...

Embodiment 2

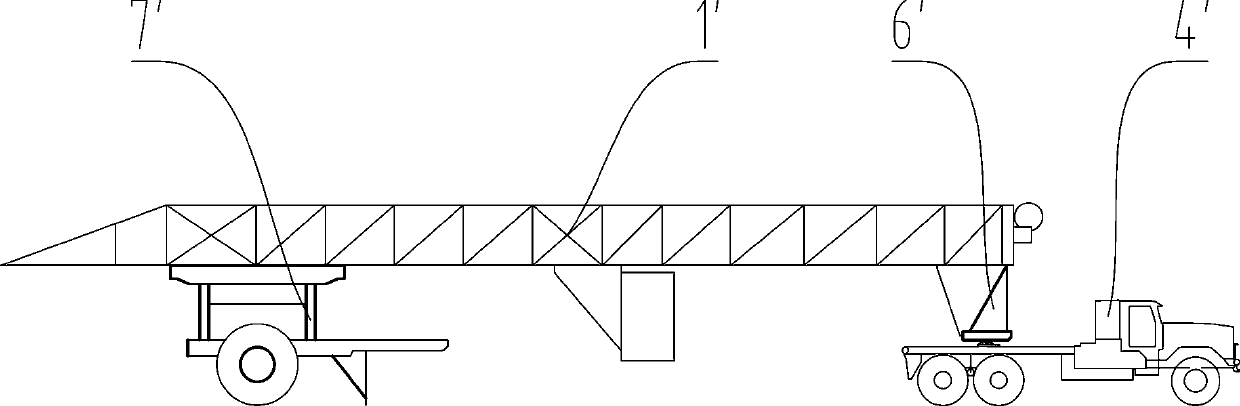

[0123] Such as Figure 9 As shown, the base structure of the trailer-type drilling rig derrick includes a base assembly 2 connected to the foundation, a derrick assembly 1 movably connected with the base assembly 2, and a trailer frame assembly movably connected with the base assembly 2 and the derrick assembly 1 respectively. 3, also includes connecting fasteners 4 that are movably connected with the base assembly 2, the derrick assembly 1 and the trailer frame assembly 3, and the jacking cylinder that is fixedly connected with the trailer frame assembly 3 or the base assembly 2 5. The strut 6 that is movably connected with the connecting fastener 4, the tractor 7 that is movably connected with the front end of the trailer frame assembly 3, the trailer frame assembly 3, and the top is fixedly equipped with a winch A, a hydraulic station B, a rope reversing machine C and BOP control device.

[0124] In this embodiment, the number of jacking cylinders 5 is six, of which four j...

Embodiment 3

[0131] Such as Figure 10 As shown, the base structure of the trailer-type drilling rig derrick includes a base assembly 2 connected to the foundation, a derrick assembly 1 movably connected with the base assembly 2, and a trailer frame assembly movably connected with the base assembly 2 and the derrick assembly 1 respectively. 3, also includes connecting fasteners 4 that are movably connected with the base assembly 2, the derrick assembly 1 and the trailer frame assembly 3, and the jacking cylinder that is fixedly connected with the trailer frame assembly 3 or the base assembly 2 5. The strut 6 that is movably connected with the connecting fastener 4, the traction rod 9 that is movably connected with the front end of the trailer frame assembly 3, the tractor 7 that is movably connected with the traction rod 9, and the front end that is movably connected with the tail end of the derrick base 2. Field towing 8, the top of the trailer frame 3 is fixedly equipped with a winch A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com