Adhesive for bonding titanium wire with nylon and silica gel and preparation method and application method of adhesive

An application method and adhesive technology, applied in the direction of adhesives, bonding methods, etc., can solve problems such as fixture deformation, and achieve the effect of improving adhesion, increasing curing speed, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

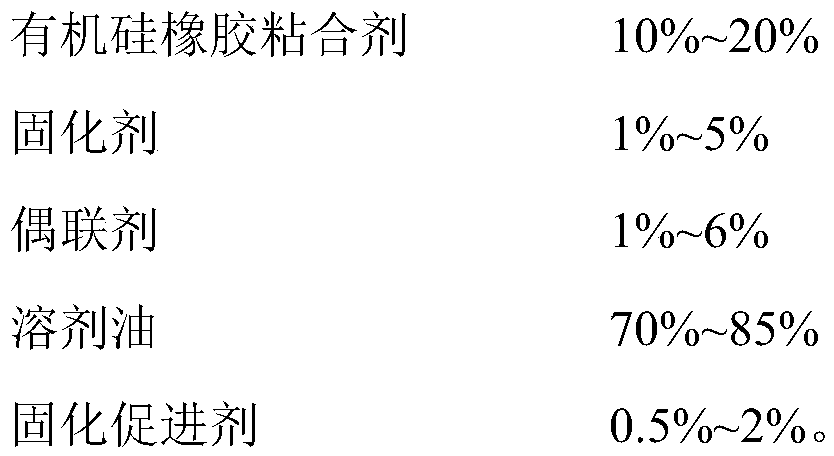

[0034] An adhesive for bonding titanium wire, nylon and silica gel, which is made from the following raw materials:

[0035]

[0036] Among them, the silicone rubber adhesive is a silicone rubber adhesive with a model of TSE3221; the curing agent is a curing agent with a model of Tm-20; the coupling agent is a coupling agent with a model of LY-105B, produced by Shandong Lanyuan Provided by New Material Technology Co., Ltd.; solvent oil is white electric oil; curing accelerator is platinum water with model PL-14.

[0037] The preparation method of the above-mentioned adhesive for bonding titanium wire and nylon and silica gel, it comprises the following steps:

[0038] Step 1. Dispersion and mixing: add silicone rubber adhesive, coupling agent and solvent oil in the container according to the formula, then disperse in a high-speed disperser for 30 minutes, and stir evenly to obtain a semi-finished product of the adhesive; this example In the middle, the speed of the high-sp...

Embodiment 2

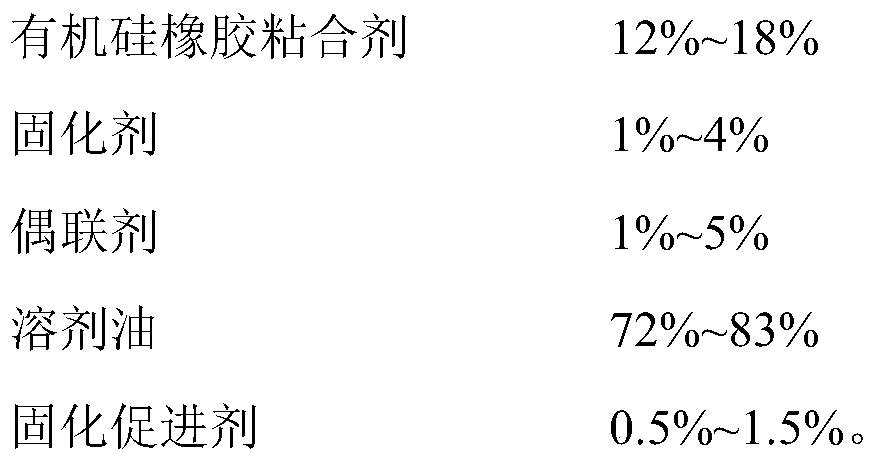

[0045] An adhesive for bonding titanium wire, nylon and silica gel, which is made from the following raw materials:

[0046]

[0047] Among them, the silicone rubber adhesive is a silicone rubber adhesive with a model of TSE3221; the curing agent is a curing agent with a model of Tm-20; the coupling agent is a coupling agent with a model of LY-105B, produced by Shandong Lanyuan Provided by New Material Technology Co., Ltd.; solvent oil is white electric oil; curing accelerator is platinum water with model PL-14.

[0048] The preparation method of the above-mentioned adhesive for bonding titanium wire and nylon and silica gel, it comprises the following steps:

[0049] Step 1. Dispersion and mixing: add silicone rubber adhesive, coupling agent and solvent oil in the container according to the formula, then disperse in a high-speed disperser for 20 minutes, and stir evenly to obtain a semi-finished product of the adhesive; this example In the middle, the speed of the high-sp...

Embodiment 3

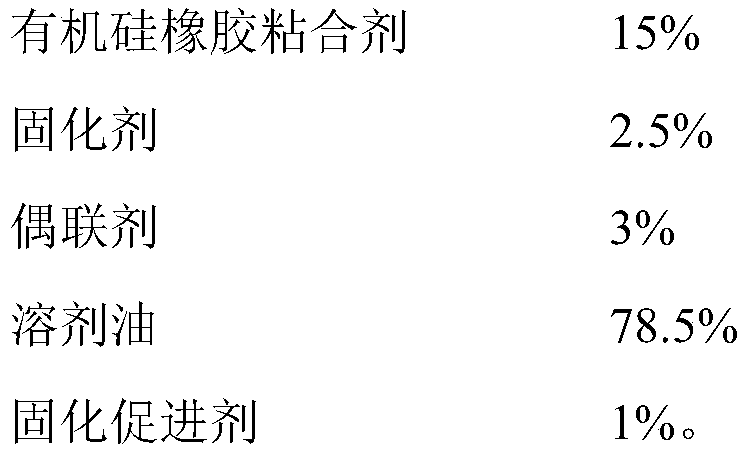

[0056] An adhesive for bonding titanium wire, nylon and silica gel, which is made from the following raw materials:

[0057]

[0058] Among them, the silicone rubber adhesive is a silicone rubber adhesive with a model of TSE3221; the curing agent is a curing agent with a model of Tm-20; the coupling agent is a coupling agent with a model of LY-105B, produced by Shandong Lanyuan Provided by New Material Technology Co., Ltd.; solvent oil is white electric oil; curing accelerator is platinum water with model PL-14.

[0059] The preparation method of the above-mentioned adhesive for bonding titanium wire and nylon and silica gel, it comprises the following steps:

[0060] Step 1. Dispersion and mixing: add silicone rubber adhesive, coupling agent and solvent oil according to the formula in the container, then disperse in a high-speed disperser for 40 minutes, and stir evenly to obtain a semi-finished product of the adhesive; this example In the middle, the speed of the high-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com