MBR biological film backwashing decontamination method

A biofilm reactor and biofilm technology, applied in the field of MBR biofilm backwashing and decontamination, can solve the problems of not effectively improving the cell population effect in the biofilm, reducing the anti-toxin ability of free cells, and blocking micropores, etc., to achieve The decontamination effect is remarkable, the decontamination effect is better, and the effect of reducing the content of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

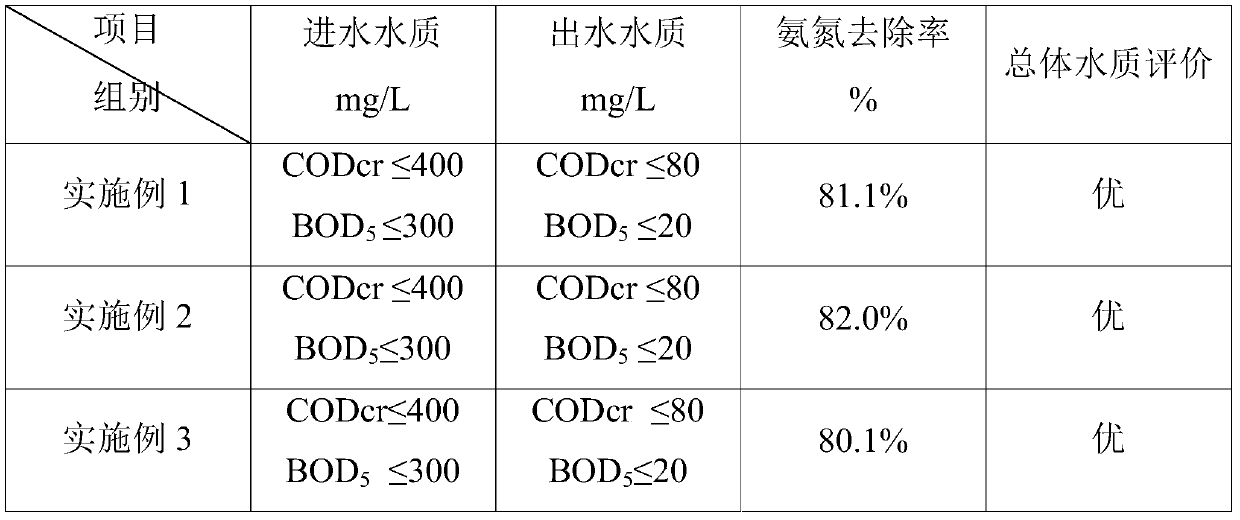

Embodiment 1

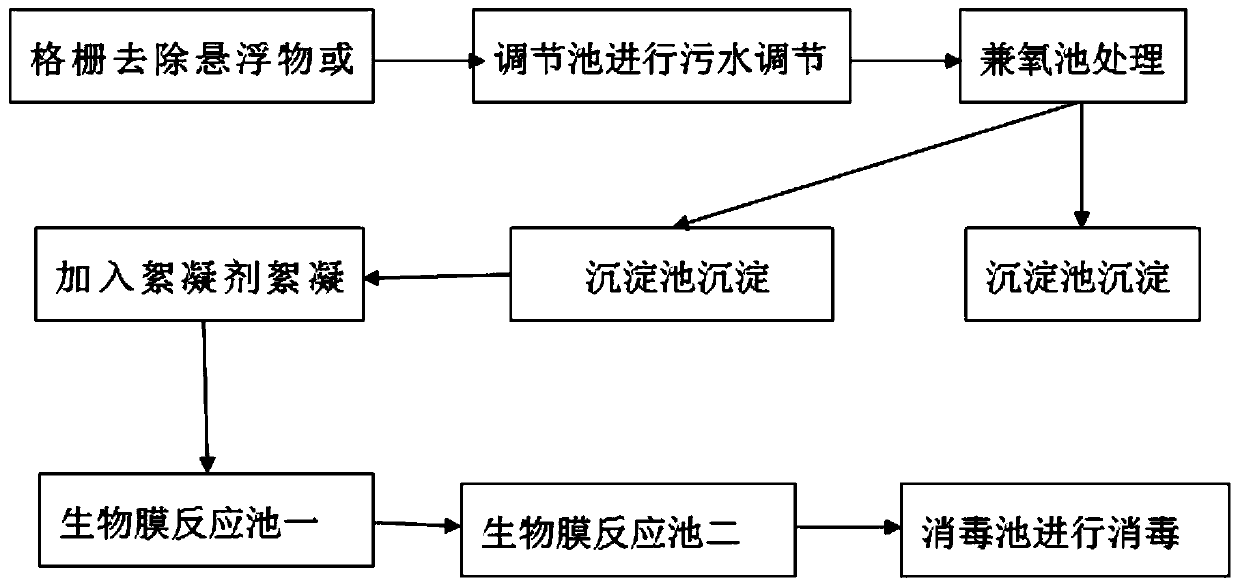

[0041] A method for MBR biofilm backwash decontamination comprises the following steps:

[0042] (1) Removal of large suspended matter or floating matter: the sewage first removes suspended matter or floating matter with a particle size greater than 15mm through a grid. The grid is an artificial grid, and the size of the grid is determined according to the water volume. This embodiment Set the water flow rate to 10m 3 / h, the water depth in front of the grid is 0.8m, and the artificial grid should be cleaned regularly. When the amount of grid slag is 0.2m3 / d, use stainless steel carbon steel mechanical rotary grid, and the grid gap is 15mm;

[0043] (2) Sewage adjustment: the sewage after removing suspended matter or floating matter with a particle size greater than 15mm is sent into the adjustment tank through the pipeline. The adjustment tank adopts an underground reinforced concrete structure to build a square plane shape, and the interior is set according to the water qualit...

Embodiment 2

[0050] A method for MBR biofilm backwash decontamination comprises the following steps:

[0051] (1) Removal of large suspended matter or floating matter: sewage first removes suspended matter or floating matter with a particle size greater than 15mm through a grid. The grid is an artificial or mechanical grid, and the size of the grid is determined according to the water volume. Setting water flow in the embodiment is 12m 3 / h, the water depth in front of the grid is 1.0m, the artificial grid should be cleaned regularly, when the amount of grid slag is 0.2m 3 / d, use stainless steel or anti-corrosion carbon steel mechanical rotary grille, the grille gap is 12mm;

[0052] (2) Sewage adjustment: the sewage after removing the suspended matter or floating matter with a particle size greater than 12mm is sent into the adjustment pool through the pipeline. The adjustment pool adopts an underground reinforced concrete structure to build a square plane shape, and the interior is set...

Embodiment 3

[0060] A method for MBR biofilm backwash decontamination comprises the following steps:

[0061] (1) Removal of large suspended matter or floating matter: sewage first removes suspended matter or floating matter with a particle size greater than 15mm through a grid. The grid is an artificial or mechanical grid, and the size of the grid is determined according to the water volume. Setting water flow in the embodiment is 15m 3 / h, the water depth in front of the grid is 1.0m, the artificial grid should be cleaned regularly, when the amount of grid slag is 0.2m 3 / d, use stainless steel or anti-corrosion carbon steel mechanical rotary grille, the grille gap is 15mm;

[0062] (2) Sewage adjustment: the sewage after removing suspended matter or floating matter with a particle size greater than 15mm is sent into the adjustment tank through the pipeline. The adjustment tank adopts an underground reinforced concrete structure to build a square plane shape, and the interior is set acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com