A press for manufacturing precision bearings

A technology of precision bearings and presses, which is applied in the field of bearing manufacturing, can solve the problems of uneven distribution, reduction of flow area, and rise in oil temperature of intelligent press-fitting machines, so as to increase the removal effect, avoid asphalt accumulation, and increase the oil return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

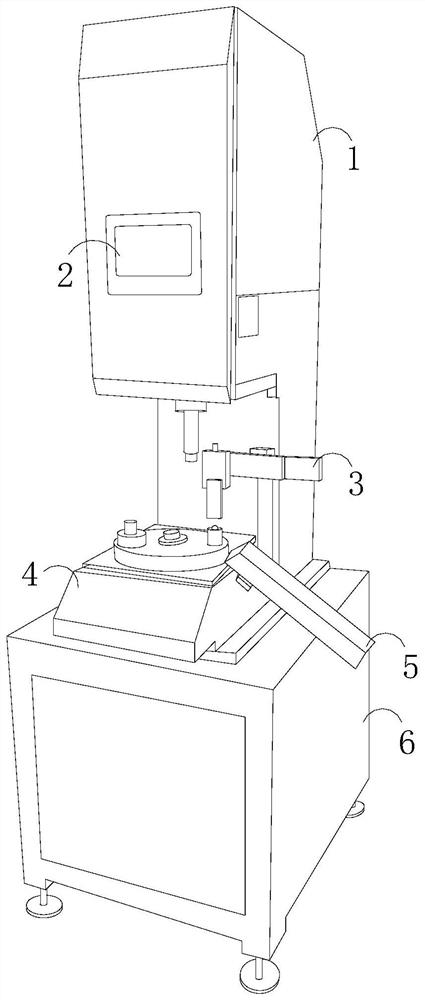

[0023] see Figure 1-Figure 5 , the present invention provides a precision bearing manufacturing press, the structure of which includes a hydraulic tank 1, a display screen 2, a detection head 3, a wheel set clamping mechanism 4, a support 5, a bed 6, and a throttle pipe 7. A hydraulic cylinder 1 is installed vertically on one side of the top surface of the bed 6, a display screen 2 is installed on the hydraulic tank 1, a wheel pair clamping mechanism 4 is installed on the top surface of the bed 6, and the wheel pair clamping mechanism 4 Facing the hydraulic tank 1, the side of the wheel pair clamping mechanism 4 is equipped with a detection head 3 through the support 5. The hydraulic tank 1 mainly includes a main hydraulic cylinder, an auxiliary hydraulic cylinder and an oil return system. The throttling Pipeline 7 is one of the components of the oil return system;

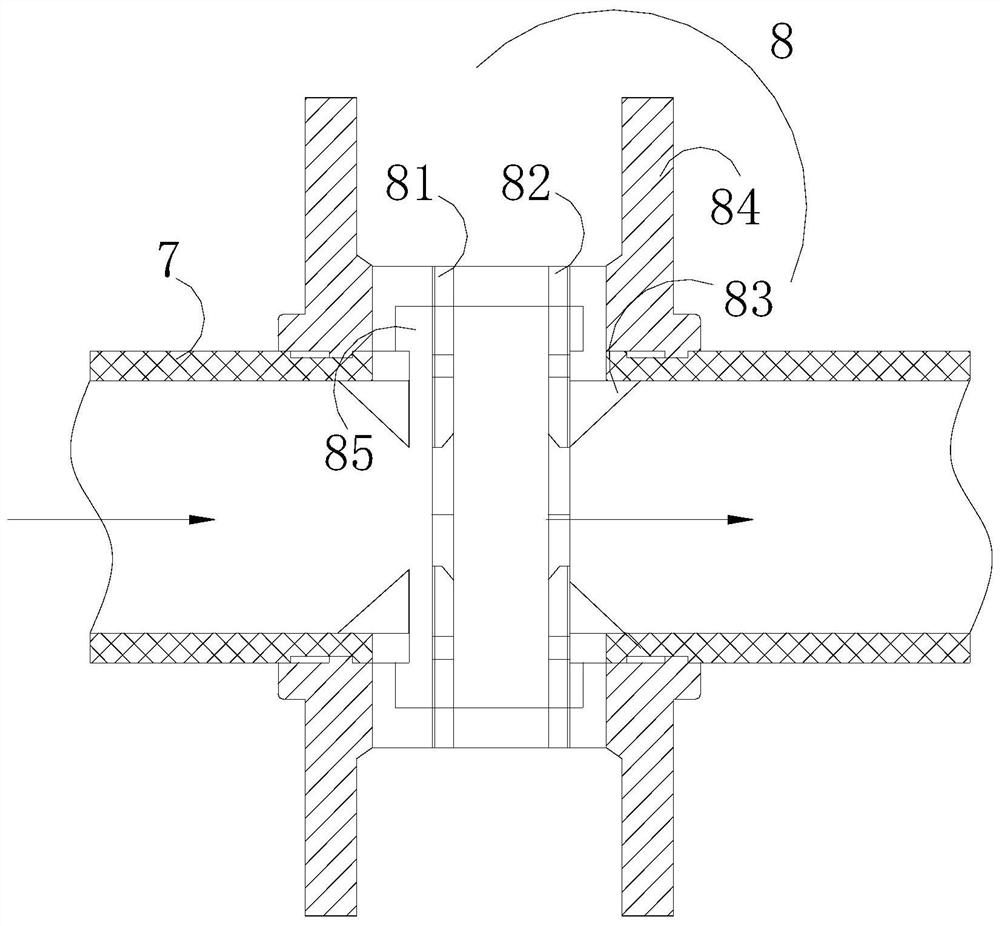

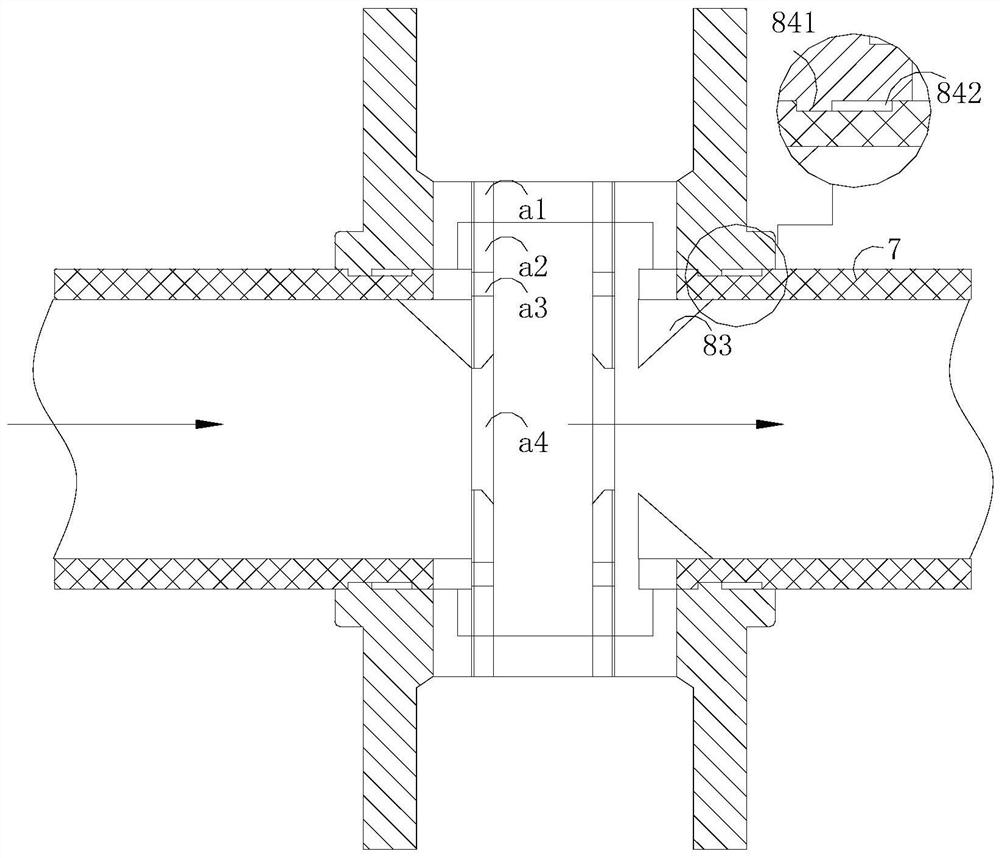

[0024] The throttling pipe 7 is provided with a throttling structure 8, and the throttling structure 8 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com