Synchronous jacking system for prefabricated box girder template

A technology of synchronous jacking and control system, applied in lifting devices, manufacturing tools, ceramic molding workshops, etc., can solve the problem of low pre-camber work efficiency, and achieve the effect of shortening construction period, reducing occupation, and saving land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

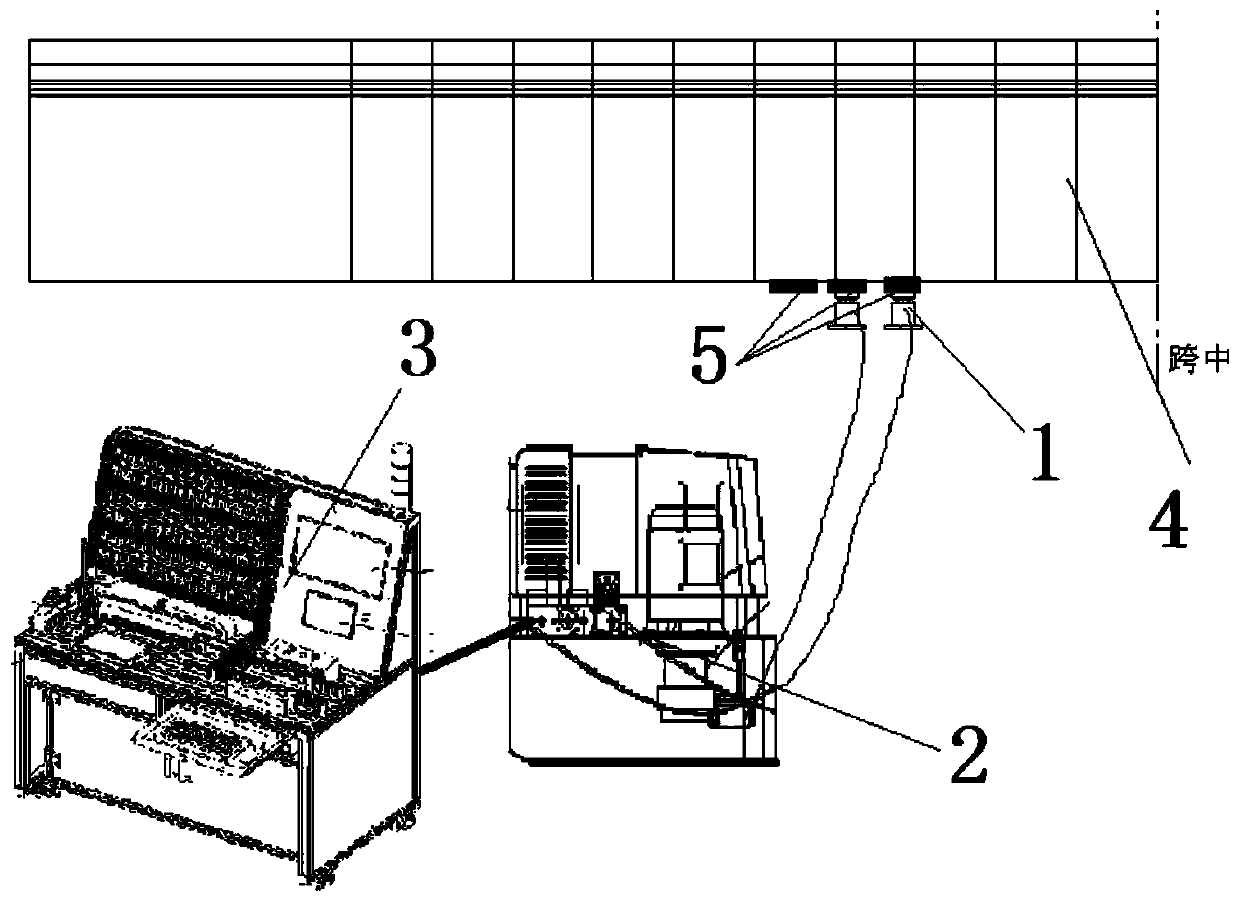

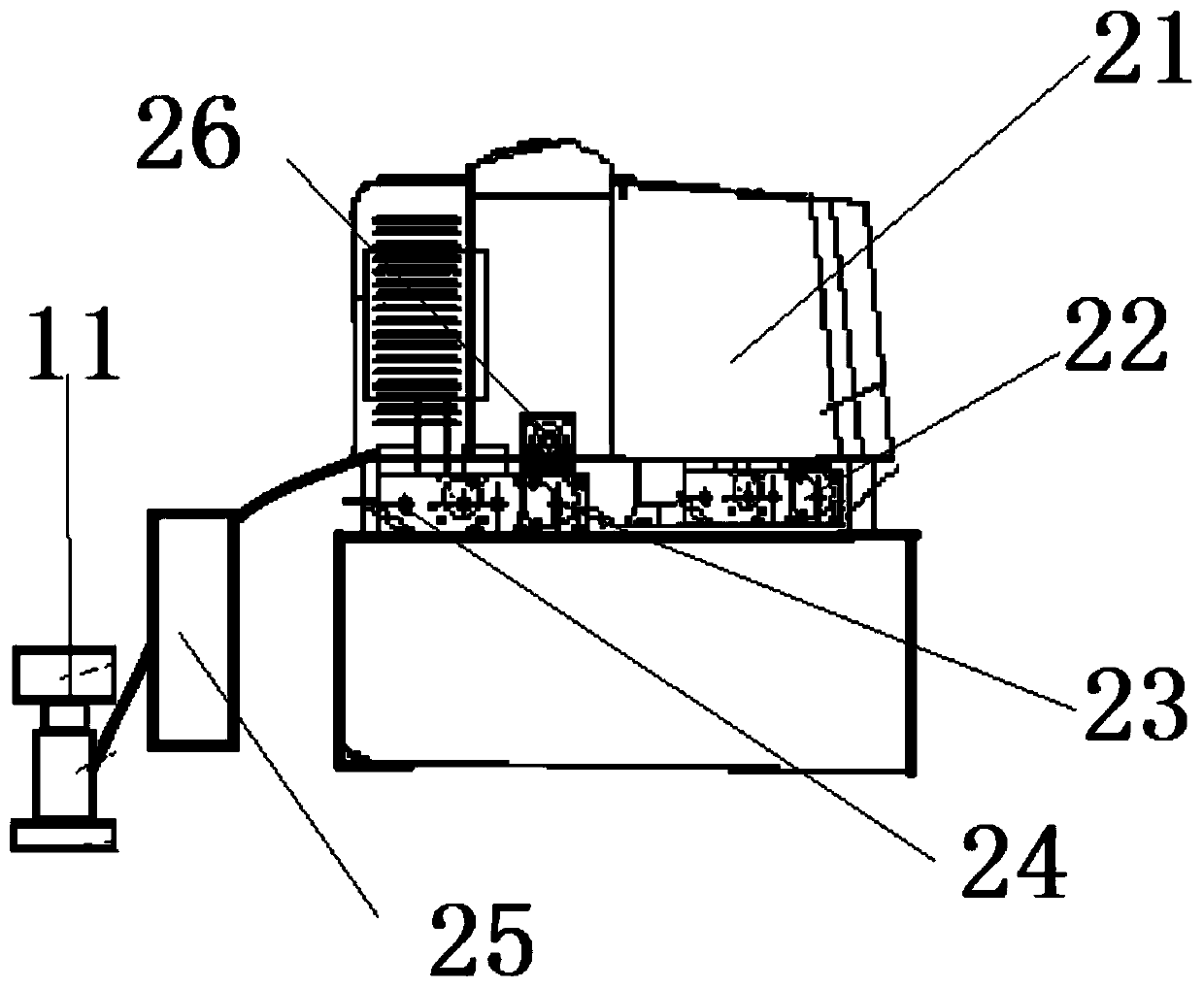

[0053] like figure 1 As shown, a synchronous jacking system for box girder formwork includes a jacking system 1, a power system 2, a control system 3, a prefabricated box girder formwork body 4 and a sensor 5, and the jacking system 1 is uniformly and longitudinally arranged on the prefabricated box girder formwork body 4. At the lower end, the power system 2 is connected to the jacking system 1 to provide power for the jacking system 1. The control system 3 is connected to the power system 2 to control the power system 2 to provide power for the jacking system 1. The sensor 5 is set in the prefabricated box The beam formwork body 4 is also connected to the control system 3 for transmitting the situation of the prefabricated box girder formwork body 4 to the control system 3. The jacking system 1 includes at least one pair of jacks 11, and the jacks 11 located in the same longitudinal row pass through the power system 2 in parallel.

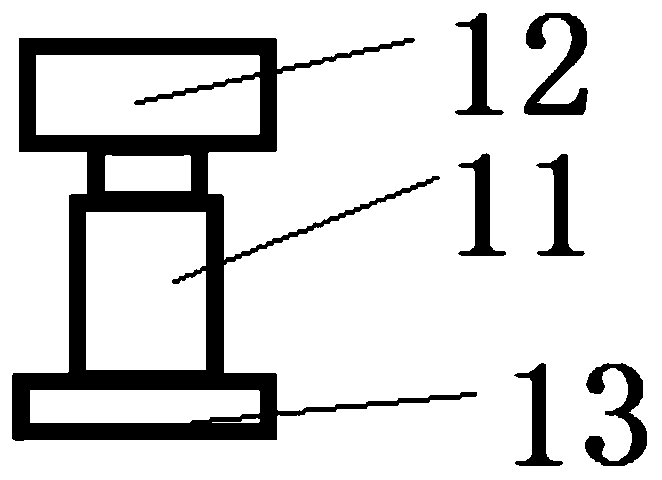

[0054] like figure 2 As shown, the jack...

Embodiment 2

[0071] like figure 1 As shown, it includes jacking system 1, power system 2, control system 3, prefabricated box girder formwork body 4 and sensor 5. 1 is connected to provide power for the jacking system 1, the control system 3 is connected to the power system 2 to control the power system 2 to provide power for the jacking system 1, and the sensor 5 is set on the prefabricated box girder formwork body 4 and connected to the control system 3 It is used to transmit the situation of the prefabricated box girder formwork body 4 to the control system 3 .

[0072] like figure 2 As shown, the jacking system 1 includes five jacks 11 uniformly arranged in each row, beams 12 and steel plates 13 , and the jacks 11 located in the same vertical row are connected in parallel through the power system 2 . The crossbeam 12 is evenly and horizontally arranged at the lower end of the box girder formwork body 4 , the jack 11 is evenly and horizontally arranged at the lower end of the crossbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com