Temperature detecting and self-cleaning cooling device for arc fuse wire additive manufacturing

A technology of additive manufacturing and cooling devices, which is applied in the direction of measuring devices, manufacturing tools, additive processing, etc., can solve the problems of reduced printing efficiency, sputtered metal pollution damage, and no dust removal device, etc., to improve the forming dimensional accuracy and quality , Guarantee measurement accuracy or stability, accurate detection and control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the drawings and embodiments.

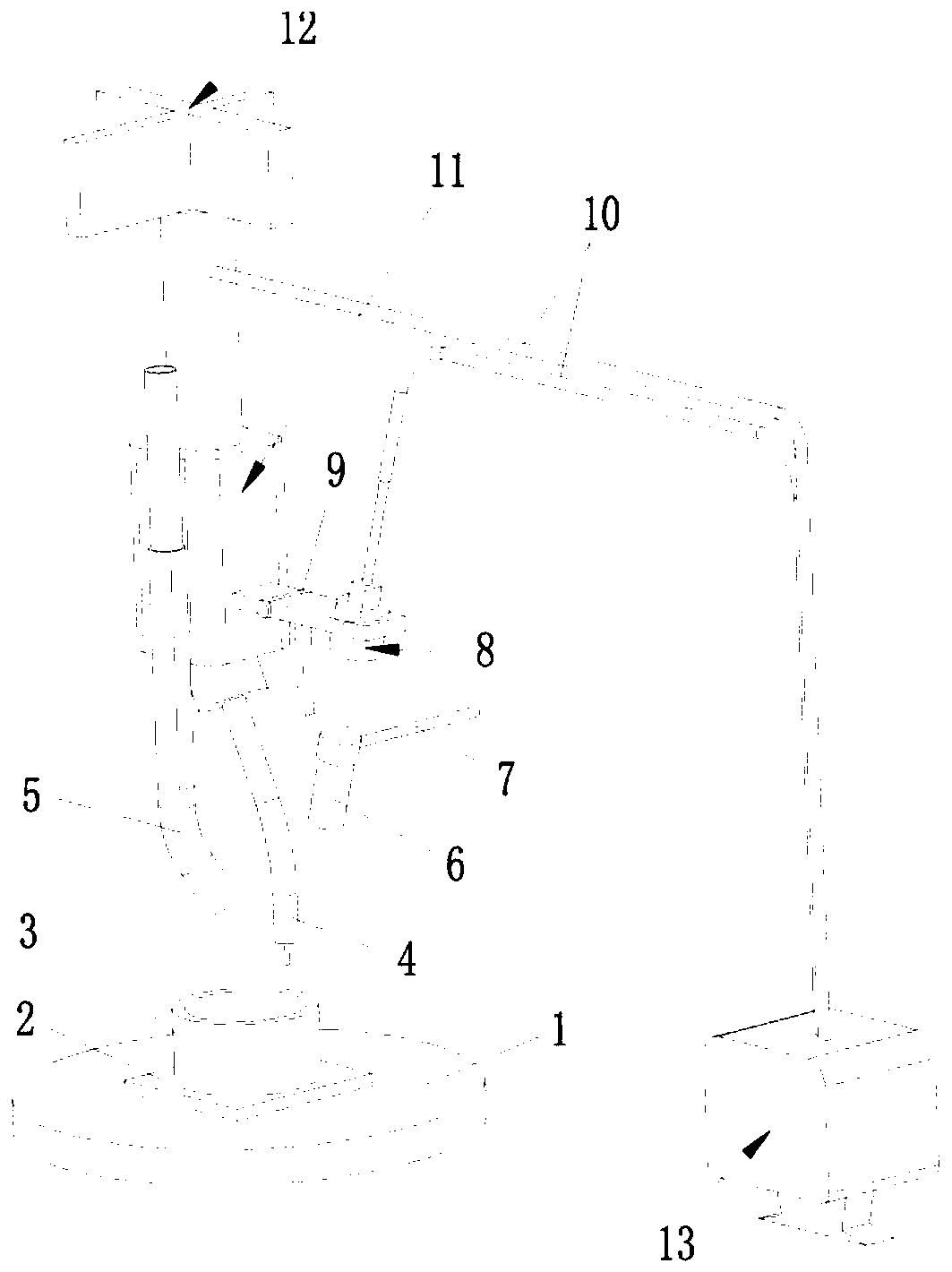

[0022] Such as figure 1 As shown, a temperature detection and self-cleaning cooling device for arc fuse additive manufacturing includes a printing device, the printing device includes a printing substrate 1, the upper end of the printing substrate 1 is provided with a printing base plate 2, and the upper end of the printing base plate 2 is provided There is a printing body 3 corresponding to the welding gun head 4, a printing welding system 11 is arranged above the printing device, a machine tool moving system is arranged at the upper end of the printing welding system 11, and the printing welding system 11 is arranged at the lower end. The welding torch head 4 used in conjunction with the printing device, one side of the printing welding system 11 is connected with a non-contact infrared thermometer 8 through a universal connecting rod 9, and the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com