Water-saving industrial silt screening equipment

A screening equipment, water-saving technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of unfavorable economic development mode, polluted soil or water source, slow screening speed, etc., to achieve high utilization rate of mechanical kinetic energy, automation The effect of high degree and fast screening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

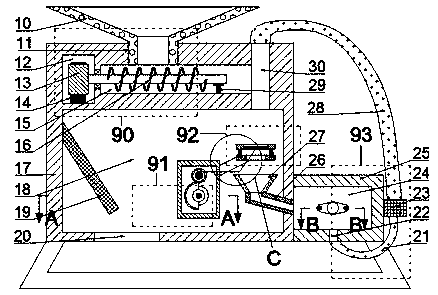

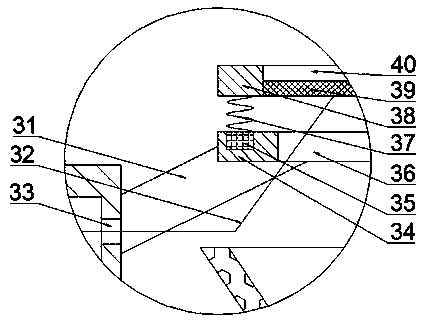

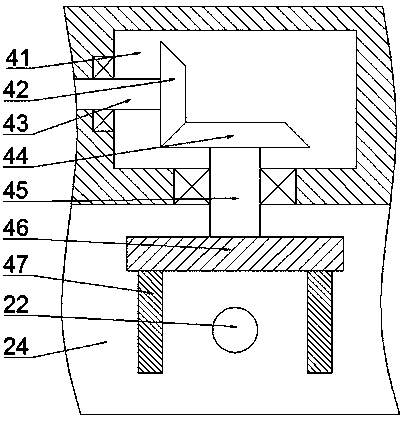

[0025] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0026] combined with Figure 1-5 The water-saving industrial sediment screening equipment mainly includes a material transport mechanism 90, a slag rejection mechanism 91, a vibration screening mechanism 92, a stirring water injection mechanism 93, a left transmission assembly 94, and a right transmission assembly 95;

[0027] The vibration screening mechanism 92 utilizes water flow to scour and vibrate to screen steel slag. The slag rejection mechanism 91 can throw out the steel slag. The above-mentioned right transmission assembly 95 drives the above-mentioned stirring and water injection mechanism 93 to recycle the water source. The above-mentioned left transmission assembly 94 dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com