Mussel bionic adhesive-calcium phosphate high-strength bone repair material, high-strength composite cap scaffold and preparation method thereof

A bionic adhesive and high-strength technology, applied in the field of medical biomaterials, can solve problems such as insufficient mechanical properties, insufficient printability and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

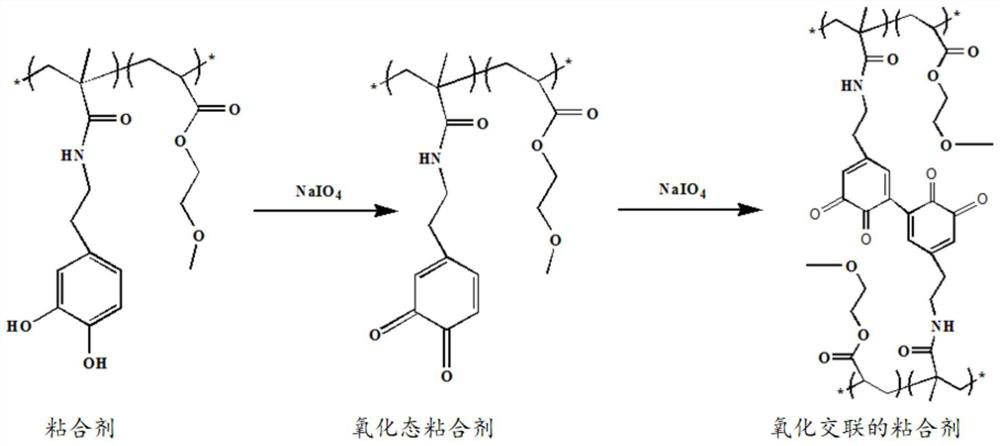

Method used

Image

Examples

Embodiment 1

[0039] A mussel bionic adhesive-calcium phosphate high-strength bone repair material comprises 15 parts by weight of the bionic adhesive, 90 parts of calcium phosphate salt and 100 parts of deionized water.

[0040] Preferably, the biomimetic adhesive is prepared by dissolving 3 parts by weight of 3.4-dihydroxyphenylmethacrylamide methoxyethyl acrylate copolymer in 10 parts by weight of a mixed solvent, and the mixed solvent is anhydrous ethanol and Ethylene glycol is prepared by mixing 1:3 by volume.

[0041] Preferably, the calcium phosphate salt is made by mixing α-tricalcium phosphate, hydroxyapatite, dibasic calcium phosphate dihydrate and calcium carbonate in a weight ratio of 1:1:1:1.

[0042] A method for preparing a mussel bionic adhesive-calcium phosphate high-strength bone repair material includes the following steps:

[0043] (1) Mix the biomimetic binder, calcium phosphate salt and deionized water in proportion and stir evenly (stirring time is 20 min, rotating speed is 1...

Embodiment 2

[0053] A mussel bionic adhesive-calcium phosphate high-strength bone repair material is characterized in that it comprises 35 parts of bionic adhesive, 85 parts of calcium phosphate salt and 105 parts of deionized water in parts by weight.

[0054] Preferably, the biomimetic adhesive is prepared by dissolving 3 parts by weight of 3.4-dihydroxyphenylmethacrylamide methoxyethyl acrylate copolymer in 10 parts by weight of a mixed solvent, and the mixed solvent is anhydrous ethanol and Ethylene glycol is prepared by mixing 1.1:3.2 by volume.

[0055] Preferably, the calcium phosphate salt is made by mixing α-tricalcium phosphate, hydroxyapatite, dibasic calcium phosphate dihydrate and calcium carbonate in a weight ratio of 1:0.5:0.75:1.

[0056] A method for preparing a mussel bionic adhesive-calcium phosphate high-strength bone repair material includes the following steps:

[0057] (1) Mix the biomimetic binder, calcium phosphate salt and deionized water in proportions and stir evenly (s...

Embodiment 3

[0067] A mussel bionic adhesive-calcium phosphate high-strength bone repair material is characterized in that it comprises 12 parts of bionic adhesive, 95 parts of calcium phosphate salt and 100 parts of deionized water in parts by weight.

[0068] Preferably, the bionic adhesive is prepared by dissolving 2 parts by weight of 3.4-dihydroxyphenyl methacrylamide methoxyethyl acrylate copolymer in 10 parts by weight of a mixed solvent, and the mixed solvent is anhydrous ethanol and Ethylene glycol is prepared by mixing 0.8:2.5 by volume.

[0069] Preferably, the calcium phosphate salt is made by mixing α-tricalcium phosphate, hydroxyapatite, dibasic calcium phosphate dihydrate and calcium carbonate in a weight ratio of 1.2:0.75:0.75:1.

[0070] A method for preparing a mussel bionic adhesive-calcium phosphate high-strength bone repair material includes the following steps:

[0071] (1) Mix the biomimetic binder, calcium phosphate salt and deionized water in proportion and stir evenly (st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com