Reciprocating material discharging method of lotus seeds

A lotus seed and blanking technology, which is applied in the field of lotus seed processing, can solve the problems of expanding occupied space, insufficient space, and low efficiency, and achieve the effects of reducing installation height and working height, reducing occupied space, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

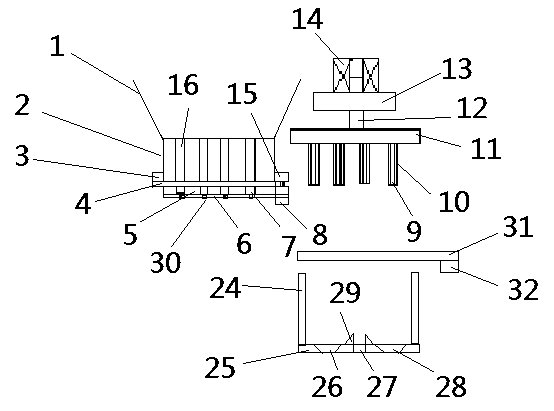

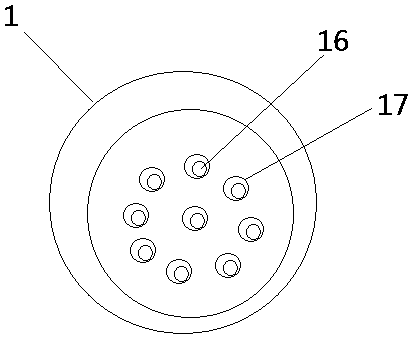

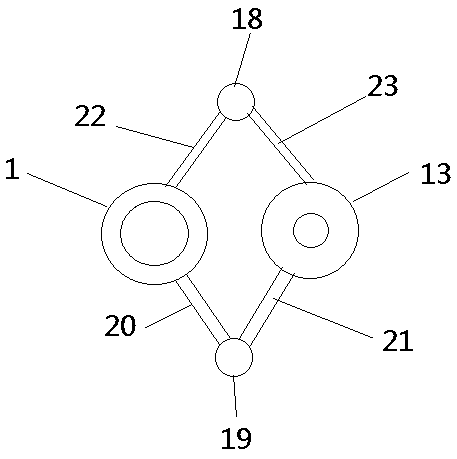

[0041] As shown in the figure: a reciprocating blanking method for lotus seeds, which controls the reciprocating movement of lotus seed processing and blanking equipment to perform blanking. Stop disc, lotus seed hole, lower stop disc motor, lotus core cutting tube, cutting ring blade, dial, drive rod, fixed frame, coil, collecting disc motor, lotus seed channel, flare, column 1, column 2, support rod 1. Support rod 2, support rod 3, support rod 4, retaining cylinder, deflector, shrinkage cavity 1, through hole, shrinkage cavity 2, triangular guide plate, lotus core hole, core picking plate, core picking plate motor;

[0042] As shown in the figure: the reciprocating blanking method includes: a collection method, a transfer method, a core drop method, and a lotus drop method; wherein the hopper is arranged above the fixed cylinder, and there are more than four lotus seed passages inside the fixed cylinder, and each lotus seed The top of the channel is provided with an outwardl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com