Real-time residual life prediction method of gear based on multi-degradation monitoring

A technology for life prediction and degradation, which is used in measurement devices, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as large gaps and inability to guarantee global convergence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Embodiment of the present invention will be further described below in conjunction with accompanying drawing:

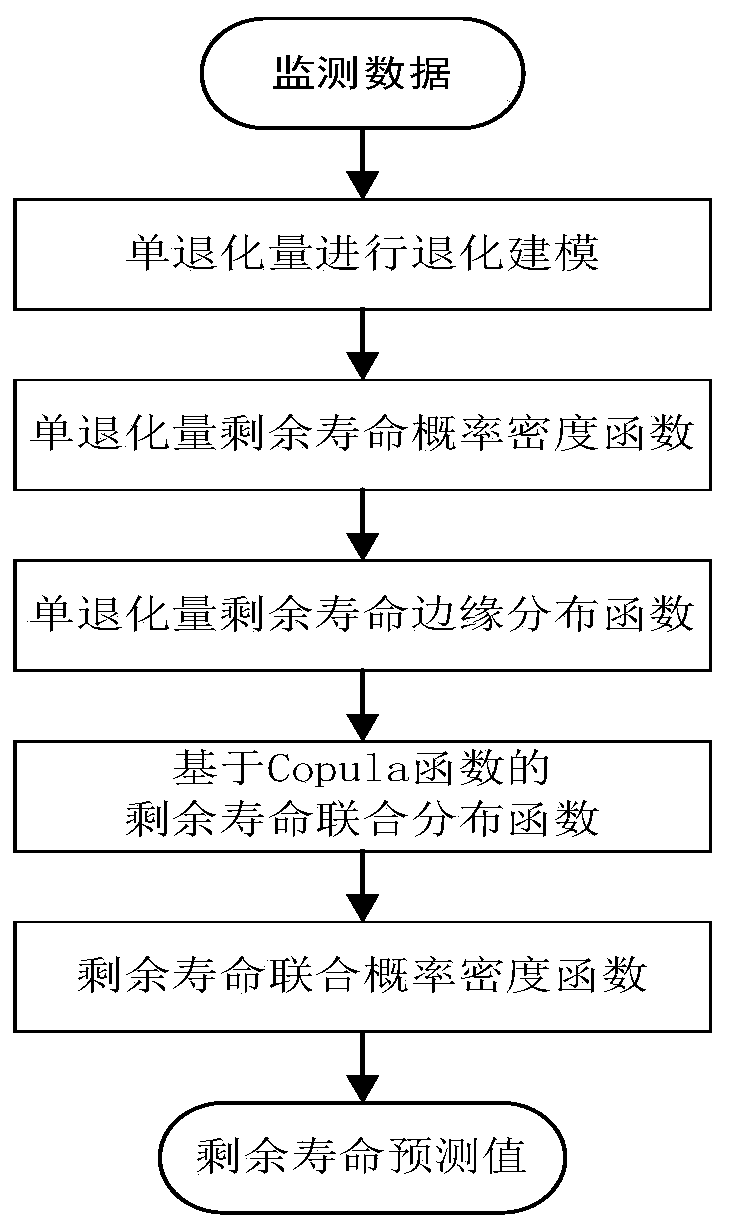

[0083] In the embodiment of the present invention, the real-time residual life prediction method of gears based on multi-degradation monitoring, the method flow chart is as follows figure 1 shown, including the following steps:

[0084] Step 1. Obtain real-time monitoring data representing the state of the internal gear of the main test gearbox 1 through the test bench:

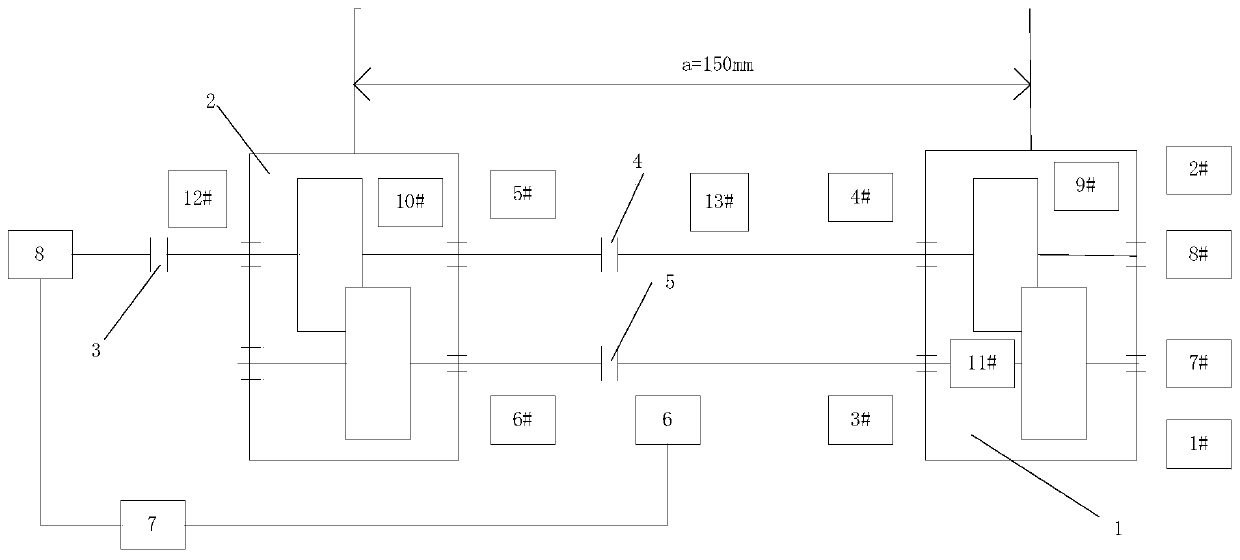

[0085] use as figure 2 For the test bench shown, the center distance of the test bench is a=150mm; the test is loaded by a mechanical lever 6; the main and accompanying gearboxes 1 and 2 are a pair of gears that are overlapped in positive and negative directions, and the gears are in the state of broken teeth Equivalent to the failure of the gear;

[0086] A total of 13 sensors are arranged in the test, such as figure 2 As shown, 1#~8# are acceleration sensors, 9# and 10# are noise senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com