Detection device for gearbox production

A detection device and gearbox technology, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of not being able to seal tightly, moving downward, and not being able to obtain accurate Data and other issues, to achieve the effect of improving accuracy, convenient operation, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

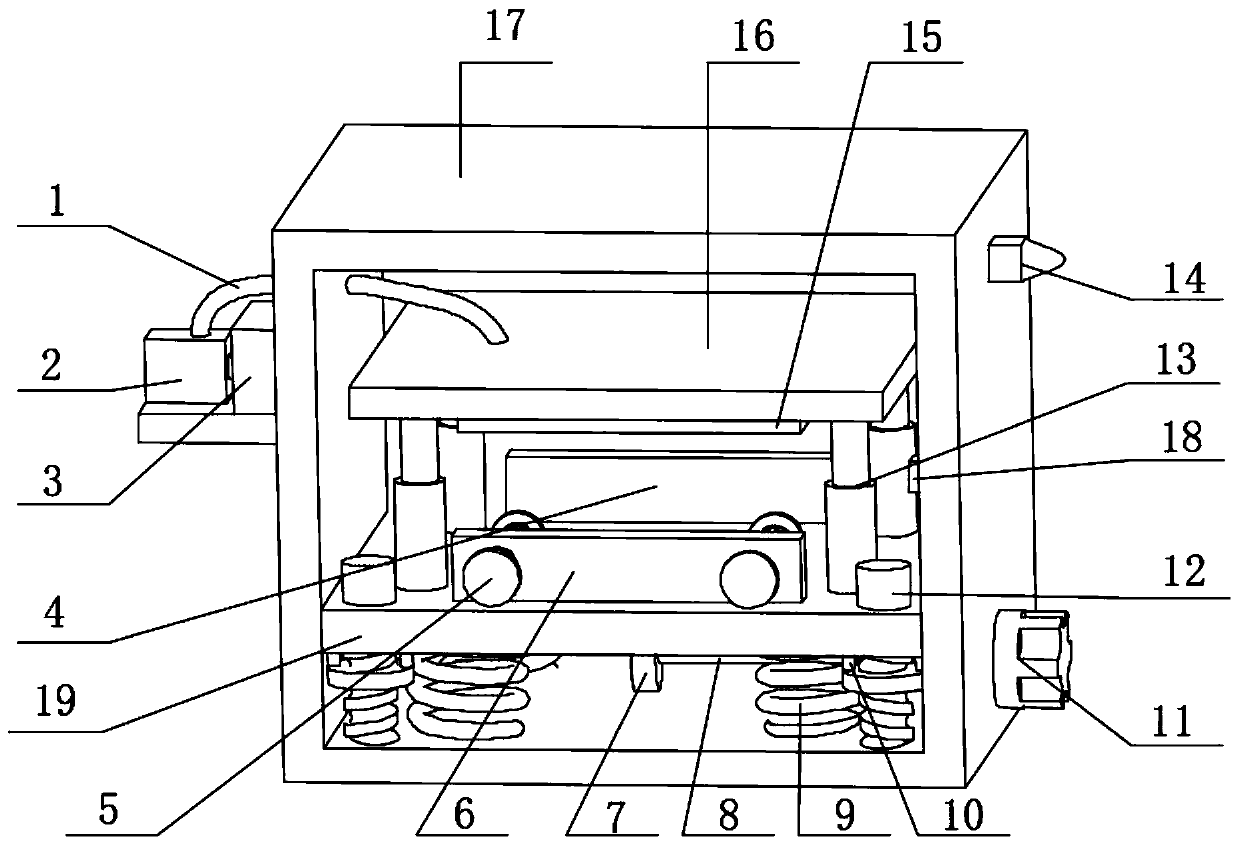

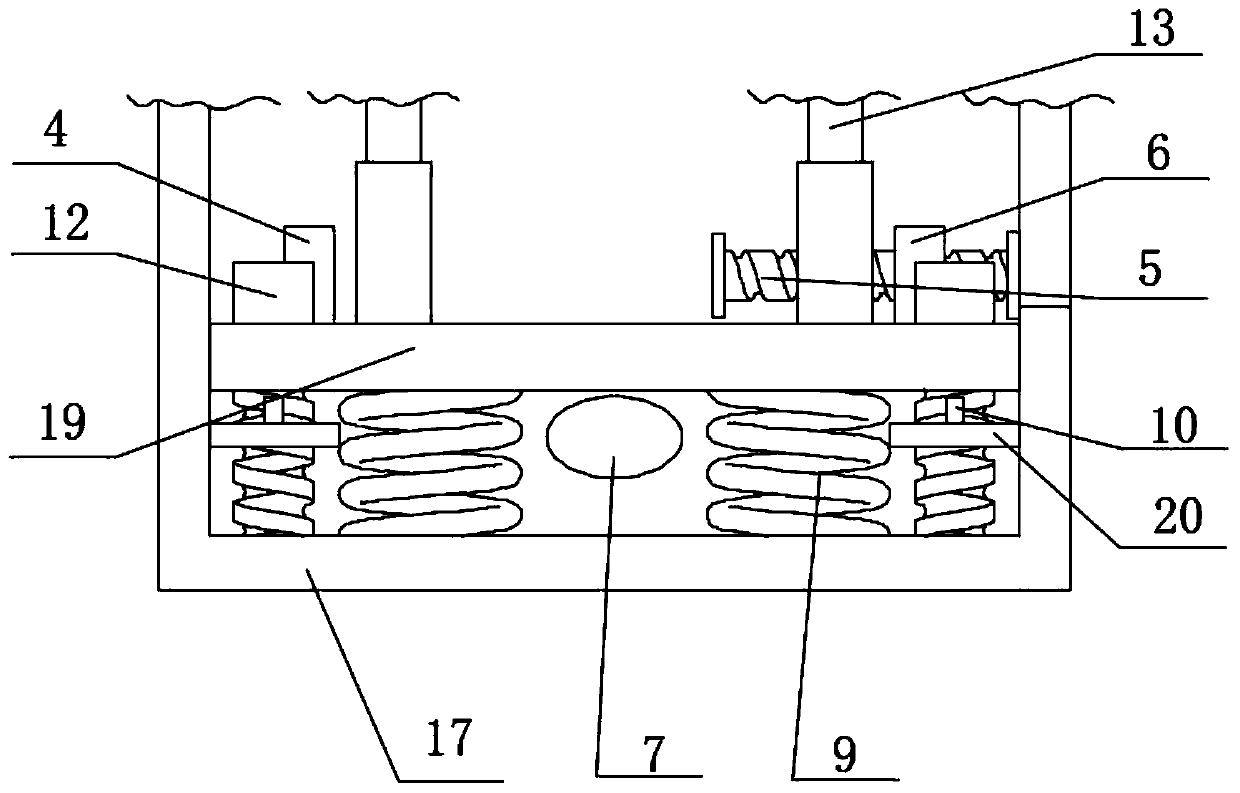

[0024] refer to Figure 1-2 , a detection device for gearbox production, comprising a fixed housing 17, the inner wall of the bottom of the fixed housing 17 is equipped with telescopic springs 9 equidistantly distributed, and the inner wall of the fixed housing 17 is slidably connected with a mounting plate 19, and the outer wall of the bottom of the mounting plate 19 It is fixedly connected with the outer wall of the top of the telescopic spring 9, and the inner walls of the four corners of the bottom of the fixed housing 17 are all equipped with limit rods 12, and the limit rod 12 extends to the top outer wall of the mounting plate 19, and the bottom of the outer wall of the limit rod 12 is provided with threads, and the limit Rod 12 is connected with circular block 20 by thread rotation, and top column 10 is all installed on the outer walls of both sides of the top of circular block 20 .

[0025] In the present invention, hydraulic cylinders 13 are installed on both sides o...

Embodiment 2

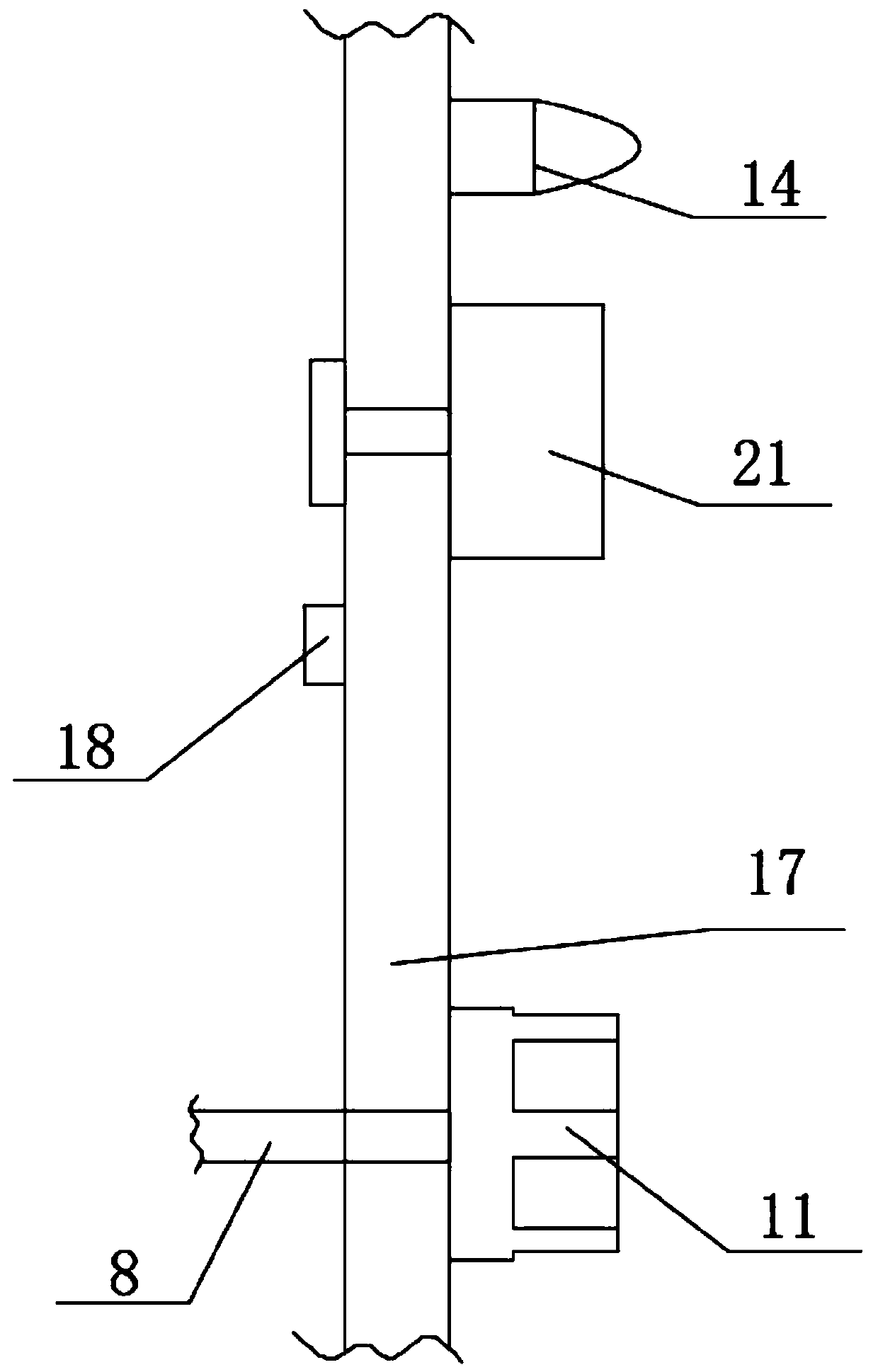

[0027] refer to Figure 1-3 , a detection device for gearbox production, which also includes an air pump 21 installed on the outer wall of one side of the fixed housing 17, and the air outlet end of the air pump 21 is connected with an air injection pipe, and the other end of the air injection pipe is connected with an air outlet bucket. After the detection is completed, open the door panel , if the detection seal is unqualified, the air pump 21 is turned on to blow off the internal argon gas, so as to avoid affecting the next detection, improve the accuracy of the detection results, and be convenient for staff to use.

[0028] Working principle: In the spare part of the device, connect all the above-mentioned driving parts, which refer to the power components, electrical devices and the adapted power supply, through wires. The specific connection means should refer to the following working principle, each electrical device The electrical connections are completed sequentially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com