Humidification cartridges for air conditioning equipment and air conditioning equipment

A technology of air conditioning equipment and wet filtration, which is applied in the field of air conditioning equipment, and can solve the problems of humidification-related technologies that need to be improved, difficulty in increasing the humidification capacity, and slow water absorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

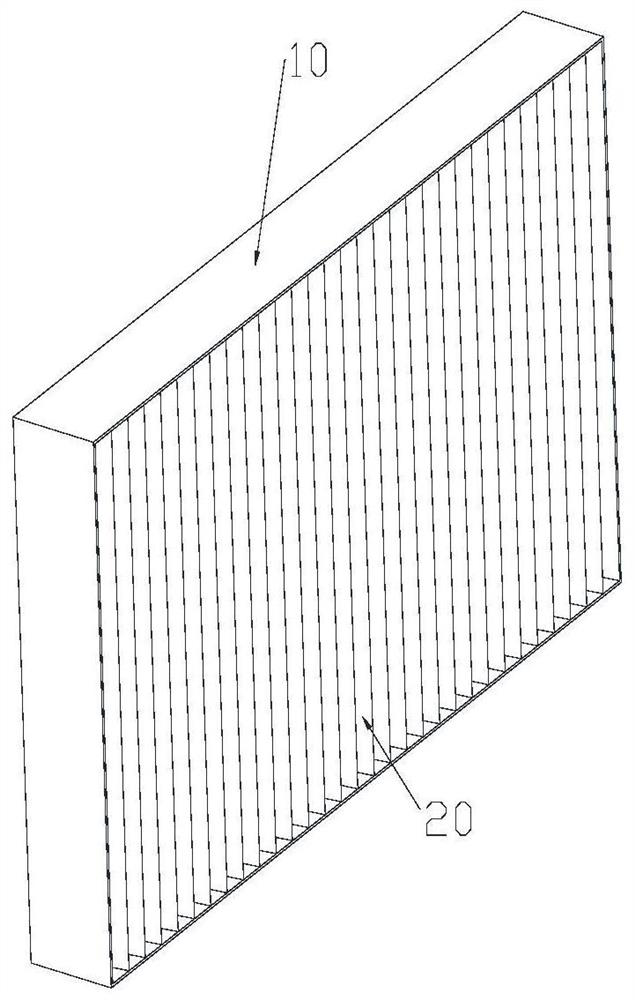

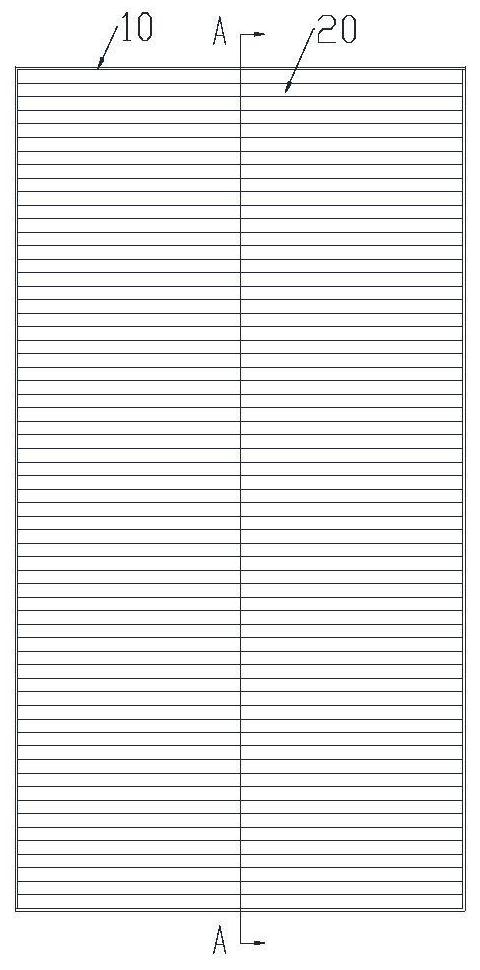

[0050] Such as image 3 As shown, use special-shaped cross-section fiber (cross-sectional shape is +) non-woven fabric as a humidification membrane to make a sawtooth-shaped humidification filter element, the sawtooth height is 10mm, and the number of teeth is 500 teeth / m. The sawtooth-shaped humidification filter element is placed vertically on the on the sink (placed as Figure 12 As shown), the humidifying filter absorbs water from the sink, the air enters from the air inlet, passes through the humidifying filter vertically, and blows the water vapor out from the air outlet. Among them, the linear density of the special-shaped cross-section fiber is 1.0dtex, the fiber length is 30mm, the specific type of fiber is polyester fiber, and the grammage of the nonwoven fabric is 90g / m 2 , the thickness is 0.5mm.

Embodiment 2

[0052] Such as image 3 As shown, use non-woven fabric with special-shaped cross-section fiber (cross-sectional shape is +) as the humidification membrane to make a sawtooth-shaped humidification filter element, the sawtooth height is 30mm, and the number of sawtooth is 300 teeth / m. on the sink (placed as Figure 12 As shown), the humidifying filter absorbs water from the sink, the air enters from the air inlet, passes through the humidifying filter vertically, and blows the water vapor out from the air outlet. Among them, the linear density of the special-shaped cross-section fiber is 1.5dtex, the fiber length is 40mm, the specific type of fiber is polyester fiber, and the grammage of the nonwoven fabric is 100g / m 2 , the thickness is 0.6mm.

Embodiment 3

[0054] Such as image 3 As shown, use special-shaped cross-section fiber (cross-sectional shape is +) non-woven fabric as a humidification membrane to make a sawtooth-shaped humidification filter element, the sawtooth height is 100mm, and the number of teeth is 150 teeth / m. The sawtooth-shaped humidification filter element is placed vertically on the on the sink (placed as Figure 12 As shown), the humidifying filter absorbs water from the sink, the air enters from the air inlet, passes through the humidifying filter vertically, and blows the water vapor out from the air outlet. Among them, the linear density of the special-shaped cross-section fiber is 2.0dtex, the fiber length is 50mm, the specific type of fiber is polyacrylonitrile fiber, and the grammage of the nonwoven fabric is 110g / m 2 , the thickness is 0.6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com