Fracturing method for transforming hot dry rock reservoir through nanometer emulsion

A nanoemulsion, dry hot rock technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of reducing the complexity of artificial fractures, short-circuiting water injection wells and production wells, and enhancing plastic mechanical characteristics and other problems, to achieve the effect of improving heat recovery efficiency, increasing net pressure, and promoting the formation of branch fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The fracturing method of a nanoemulsion reformed hot dry rock reservoir in this embodiment comprises the following steps in sequence:

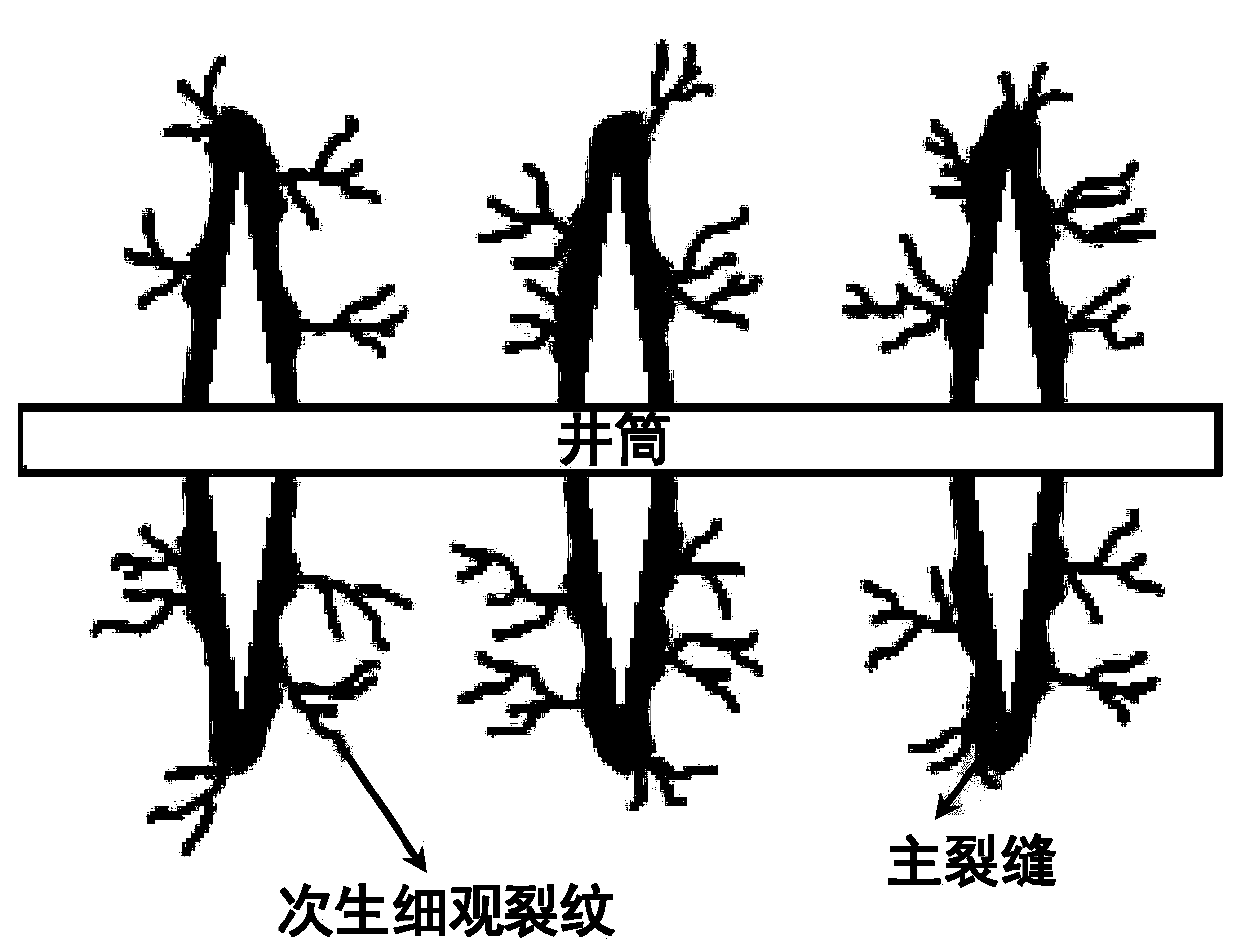

[0041] (1) choose hot dry rock development area, inject 100 cubic meters of slippery water fracturing fluid into described hot dry rock formation with a displacement of 0.5 cubic meters per minute in this area, to form main fractures;

[0042] (2) Injecting 100 cubic meters of nanoemulsions with a particle size of 50-200nm into the hot dry rock formation at a displacement of 0.5 cubic meters per minute, forming a plurality of microscopic fractures on the basis of the main fractures ; The nanoemulsion is formed by mixing and stirring the raw materials of the following parts by weight: 0.04 parts by weight of n-dodecane, 4 parts by weight of cetyltrimethylammonium chloride, 14 parts by weight of n-butanol and 40 parts by weight of water , the stirring rate is 300rpm, and the stirring time is 30min;

[0043] (3) Inject 30 cubic meters of ...

Embodiment 2

[0049] The fracturing method of a nanoemulsion reformed hot dry rock reservoir in this embodiment comprises the following steps in sequence:

[0050] (1) select the hot dry rock development area, inject 200 cubic meters of slick water fracturing fluid into the described hot dry rock formation with a displacement of 1.25 cubic meters per minute in this area, to form main fractures;

[0051] (2) Injecting 200 cubic meters of nanoemulsions with a particle size of 50-200nm into the hot dry rock formation at a displacement of 1.25 cubic meters per minute, forming a plurality of microscopic fractures on the basis of the main fractures ; The nanoemulsion is formed by mixing and stirring the raw materials of the following parts by weight: 0.06 parts by weight of n-dodecane, 5 parts by weight of cetyltrimethylammonium chloride, 16 parts by weight of n-butanol and 45 parts by weight of water , the stirring rate is 300rpm, and the stirring time is 35min;

[0052] (3) Inject 450 cubic me...

Embodiment 3

[0058] The fracturing method of a nanoemulsion reformed hot dry rock reservoir in this embodiment comprises the following steps in sequence:

[0059] (1) choose hot dry rock development area, inject 300 cubic meters of slippery water fracturing fluid into described hot dry rock formation with a displacement of 2.0 cubic meters per minute in this area, to form main fractures;

[0060] (2) injecting 300 cubic meters of nanoemulsions with a particle size of 50-200nm into the hot dry rock formation at a displacement of 2.0 cubic meters per minute, forming a plurality of microscopic fractures on the basis of the main fractures ; The nanoemulsion is formed by mixing and stirring the raw materials of the following parts by weight: 0.08 parts by weight of n-dodecane, 6 parts by weight of cetyltrimethylammonium chloride, 18 parts by weight of n-butanol and 50 parts by weight of water , the stirring rate is 300rpm, and the stirring time is 34min;

[0061] (3) Inject 60 cubic meters of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com