A kind of preparation device and preparation method of spherical solid phosphoric acid

A technology of solid phosphoric acid and granular solids, which is applied in the direction of phosphoric acid, condensed phosphoric acid, phosphorus oxyacids, etc., and can solve the problems of adhering liquid and poor granularity of solid phosphoric acid particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

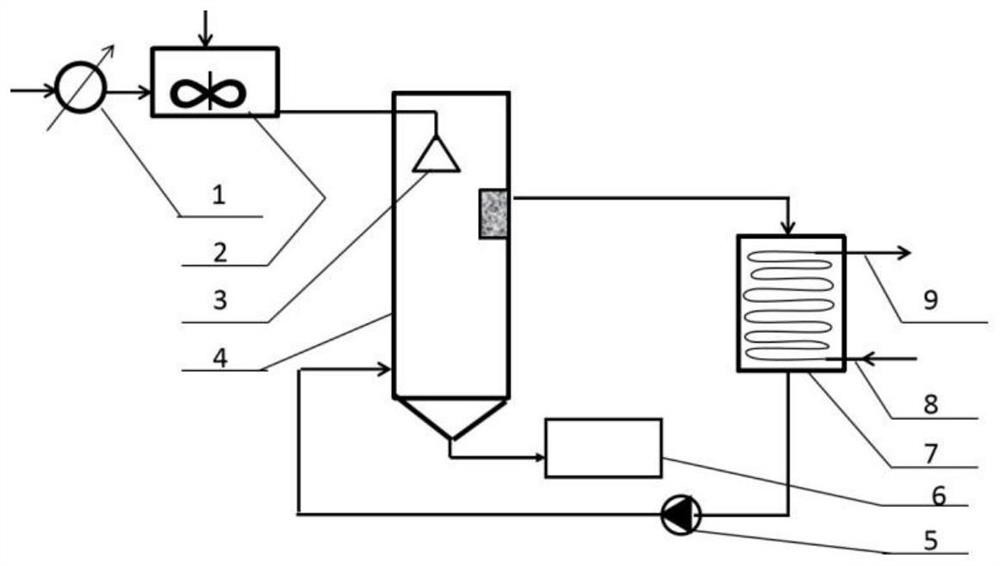

[0037] The present invention provides a preparation device for spherical solid phosphoric acid, comprising a cooling and solidification tower 4, the bottom of the cooling and solidification tower 4 is provided with a discharge port, and the discharge port is connected with a solid-liquid separation device 6 through a conveying pipeline, as In a preferred manner, the solid-liquid separation device 6 includes a filter centrifuge and a drying device connected in sequence, and the drying device is preferably a purging device or a vacuuming device. The bottom of the cooling and solidification tower 4 is provided with the first cooling medium inlet, and the top in the cooling and solidification tower 4 is provided with the first cooling medium outlet and the drip tray 3, and the height position of the drip tray 3 is located at the first Above the height of the cooling medium outlet.

[0038] In order to realize the functions of controlling the temperature of liquid phosphoric acid a...

Embodiment 1

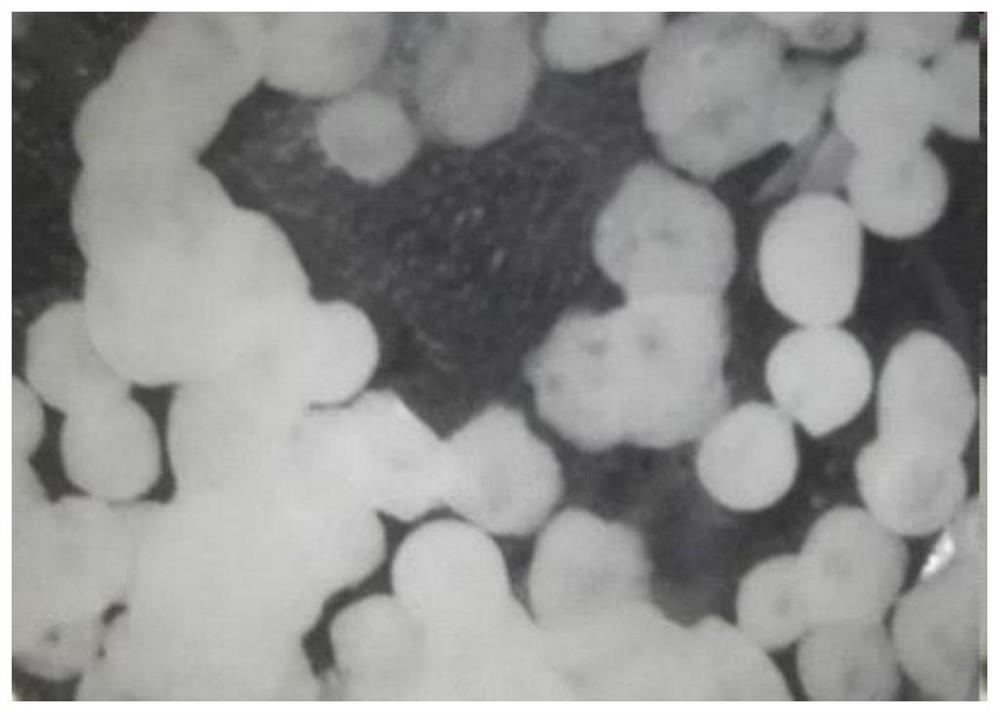

[0049] Mass fraction is that the phosphoric acid liquid of 91.5wt% is adjusted to 29 ℃ through the phosphoric acid temperature regulating heat exchanger 1 and then sent into the crystal slurry tank 2, and in the crystal slurry tank 2, add phosphoric acid liquid quality 10wt% phosphoric acid hemihydrate crystal (small particle solid Phosphoric acid), stirred at 1000rpm in the magma tank for 20 minutes to obtain phosphoric acid magma. Phosphoric acid crystal slurry forms crystal slurry droplets with a diameter of about 5 mm through the drip tray 3 and drops them into petroleum ether with a boiling range of 60-90° C. as a cooling medium in the cooling solidification tower. Petroleum ether as a cooling medium overflows from the upper part of the cooling and solidification tower 4 and flows into the heat exchanger 7 to be cooled to -20°C, pressurized by the pump 6, and sent from the lower part to the 5m-high tower at a superficial liquid velocity of 0.15m / s. Cooling solidification ...

Embodiment 2

[0051] Mass fraction is that the phosphoric acid liquid of 100wt% is adjusted to 42 ℃ through phosphoric acid thermoregulating heat exchanger 1 and then sent into the crystal slurry tank 2, in the crystal slurry tank 2, add phosphoric acid liquid quality 0.1wt% anhydrous phosphoric acid crystals (i.e. small particles Solid phosphoric acid), stirred at 2000rpm in the magma tank for 10 minutes to obtain phosphoric acid magma. Phosphoric acid magma forms magma liquid droplets with a diameter of about 2mm through the drip tray 3 and drops into the normal hexane as the cooling medium in the cooling and solidification tower. As the cooling medium, n-pentane overflows from the upper part of the cooling and solidification tower 4, is cooled to 35°C in the heat exchanger 7, and then pressurized by the pump 6, and is sent from the lower part to the 5m-high cooling tower at a superficial liquid velocity of 0.3m / s. Solidification tower 4. The descending magma liquid droplets contact with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com