Detection method and detection system for belt tearing state of belt conveyor

A state detection and conveyor technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problem that the belt is difficult to find, impossible to monitor the real-time running state of the belt in real time and accurately, and human contact equipment. Low detection accuracy and other problems, to reduce economic losses and avoid major production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

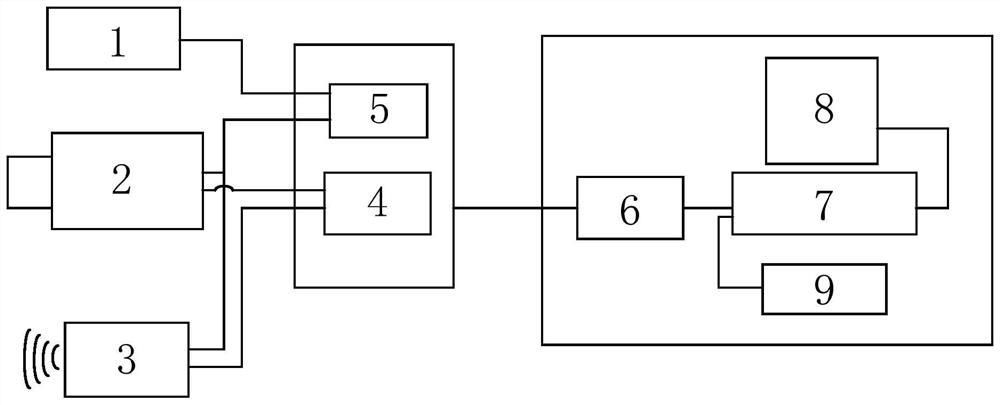

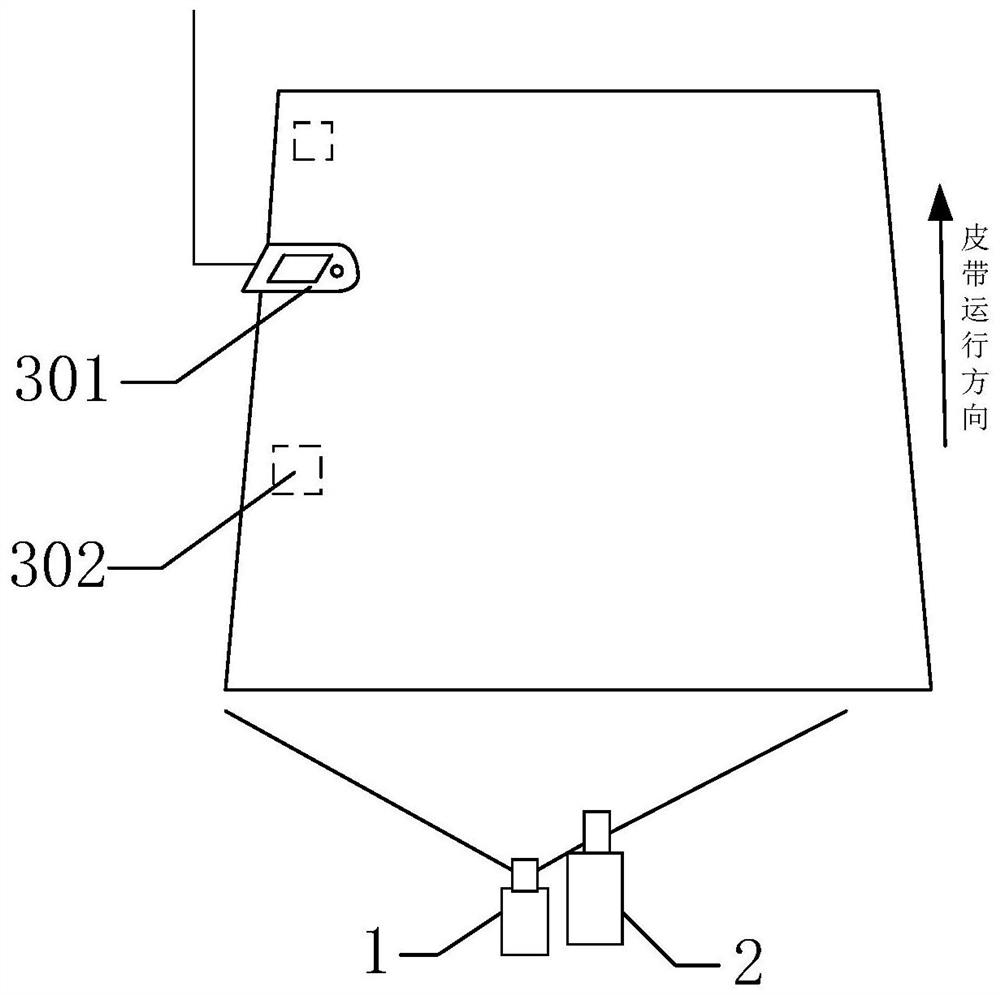

[0039] Such as figure 1 and figure 2As shown, the belt conveyor belt tear state detection system includes an image acquisition unit, a defect location unit, a transmission unit and a data processing unit; wherein,

[0040] The imaging unit includes an image acquisition device 2 arranged on one side of the belt and a laser light source 1 arranged on the adjacent side of the image acquisition device; specifically,

[0041] The image acquisition device 2 is a camera arranged in a protective cover and a zoom lens matched with the camera. The installation height of the image acquisition device 2 is lower than the installation height of the belt, and the camera lens faces the non-working surface of the belt (ie, the back of the belt) Set so that the width of the captured image exceeds the width of the belt;

[0042] In this embodiment, since the installation height of the belt is 450mm, the installation height of the image acquisition equipment is 300mm, which is lower than the i...

Embodiment 2

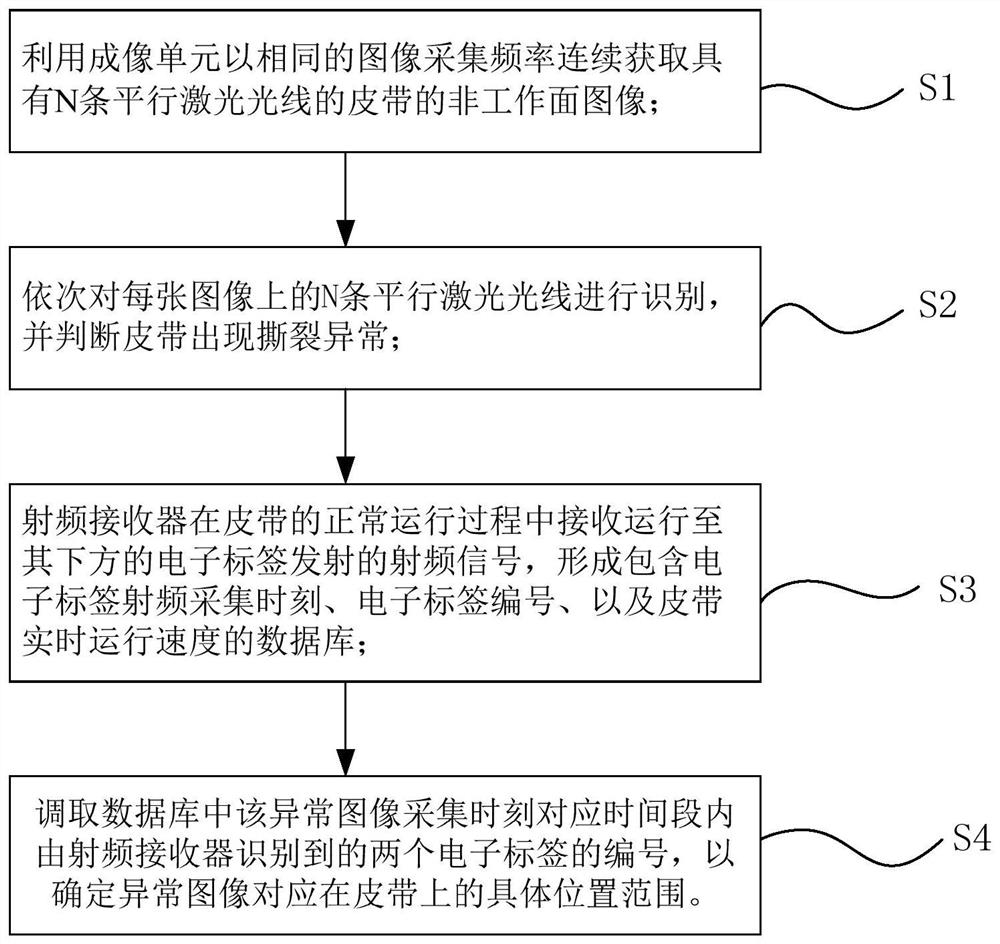

[0056] Such as image 3 As shown, a detection method implemented by a belt conveyor belt tear state detection system, the specific steps are as follows:

[0057] S1. Use the imaging unit to continuously acquire images of the non-working surface of the belt with 11 parallel laser rays at the same image acquisition frequency; wherein, the distance between two adjacent laser rays is 20 mm;

[0058] Among them, since the position of the laser light relative to the camera is fixed, the position of the laser light in the image is also fixed after the installation is completed, so the camera's setting position is adjusted to each laser light on the image collected during the debugging stage Keep the same length, brightness and clarity, and each laser line has no breakpoints, such as Figure 4 As shown; if the image acquisition range is large, the target image can also be intercepted in the image collected by the camera by setting the coordinate position of the target image to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com