Steel sheet correction mechanism and method

A technology of steel plate and steel wheel, which is applied in the field of steel plate correction mechanism and steel plate correction, and can solve the problems of low work efficiency of steel plate correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

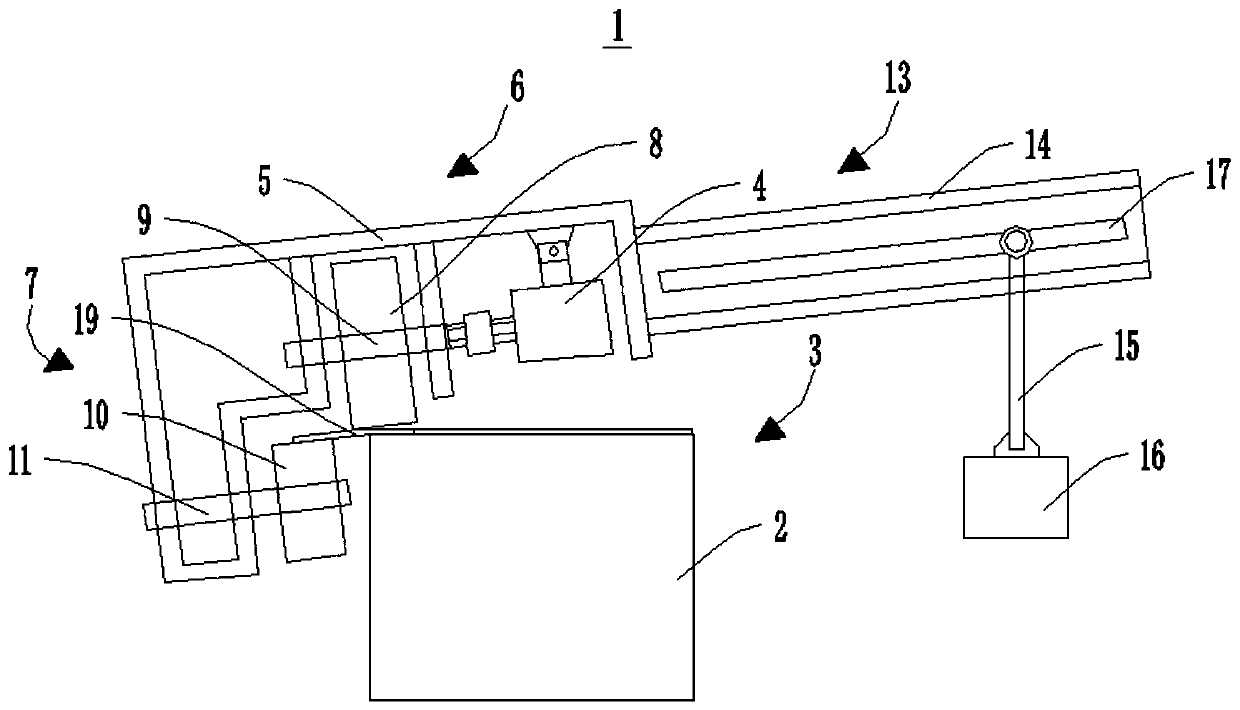

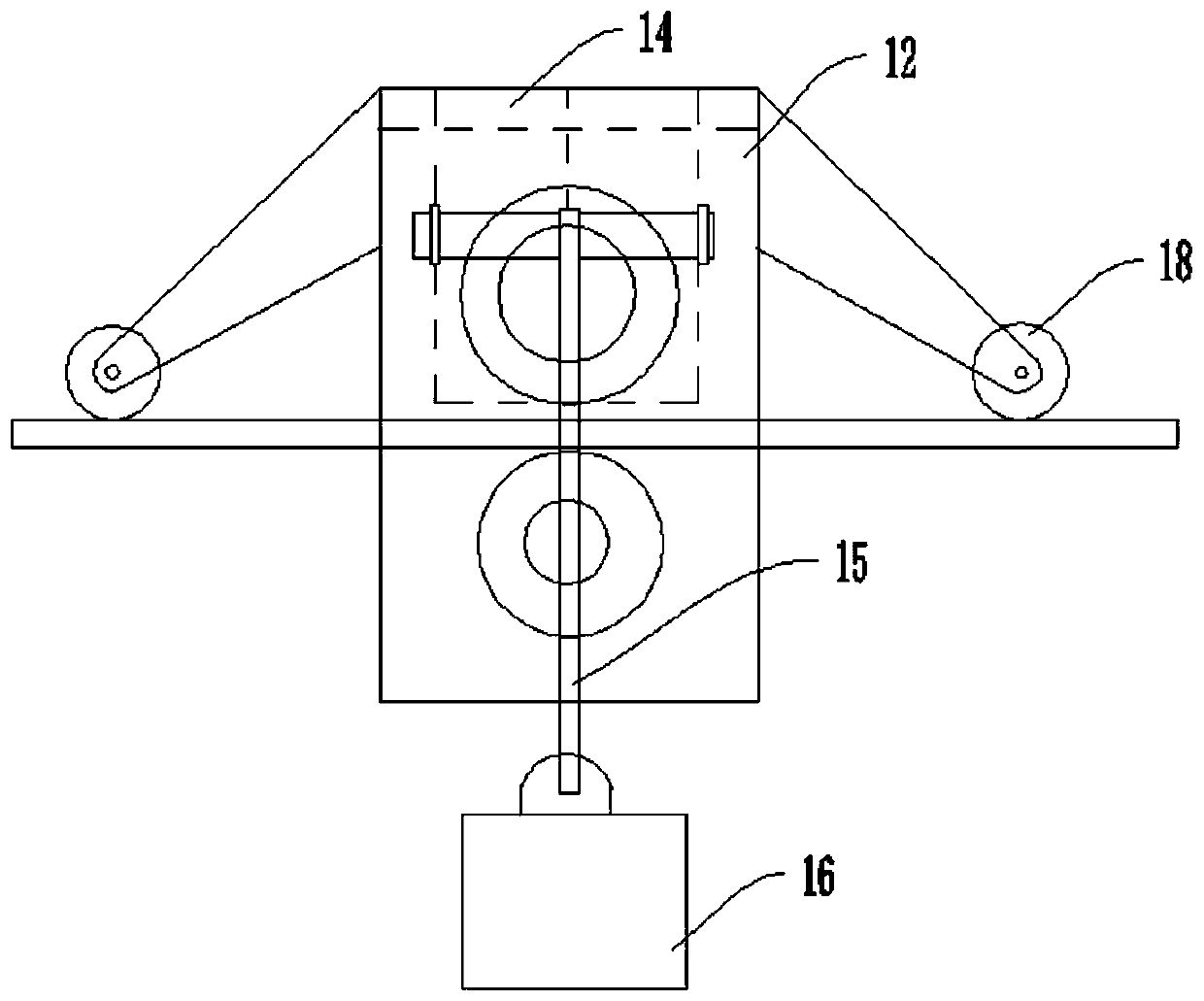

[0049] Please refer to figure 1 , with reference to figure 2 , the present application provides a steel plate correction mechanism 1 for correcting deformed steel plates 19, which includes a support structure 2, a correction assembly 3 and a drive structure 4, wherein the correction assembly 3 is obliquely arranged on the support structure 2, and can be used Rolling on the deformed steel plate 19 ; the driving structure 4 is in transmission connection with the straightening component 3 , and is used to drive the straightening component 3 to roll on the deformed steel plate 19 .

[0050] It should be noted that, in this embodiment, the support structure 2 adopts a steel box girder structure; in other embodiments, the support structure 2 may also adopt other structures according to actual usage conditions.

[0051] It should be noted that, in this embodiment, the drive structure 4 includes a geared motor, which is in transmission connection with the straightening assembly 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com