Automatic glue spraying and paving integrated machine for waterproof roll

A waterproofing membrane, integrated machine technology, applied in building insulation materials, tools for roof engineering, roofing and other directions, can solve the problems of complex structure of the whole machine, potential safety hazards, not environmental protection, etc., to achieve firm bonding and simple structure Reliable and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below by taking the laying of JSJ waterproof coiled material as an example.

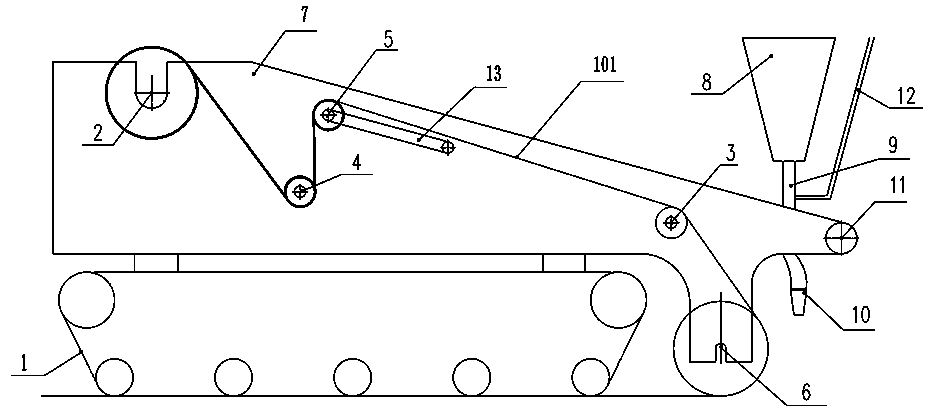

[0017] Such as figure 1 As shown, the waterproof coiled material automatic glue spraying and laying integrated machine of the present invention includes a vehicle frame with a walking mechanism and a coiled material laying mechanism placed on the vehicle frame:

[0018] In order to make the machine adapt to the laying of various complex planes when it is working, and to run smoothly, and at the same time ensure that the coiled material is laid flat and compacted, the walking mechanism of the present invention adopts a crawler structure. In actual manufacturing, the crawler 1 can use rubber crawlers Or non-climbing crawler to avoid damage to the membrane and ensure the waterproof effect of the membrane;

[0019] The coil laying mechanism of the present invention comprises a coil support roller 2 horizontally arranged at the rear of the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com