Full-automatic-feeding multi-station embroidery machine bottom thread changing system and method

A multi-station, embroidery machine technology, applied to embroidery machines, embroidery machine mechanisms, textiles and papermaking, etc., can solve problems such as high manpower input and reduced bobbin case downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

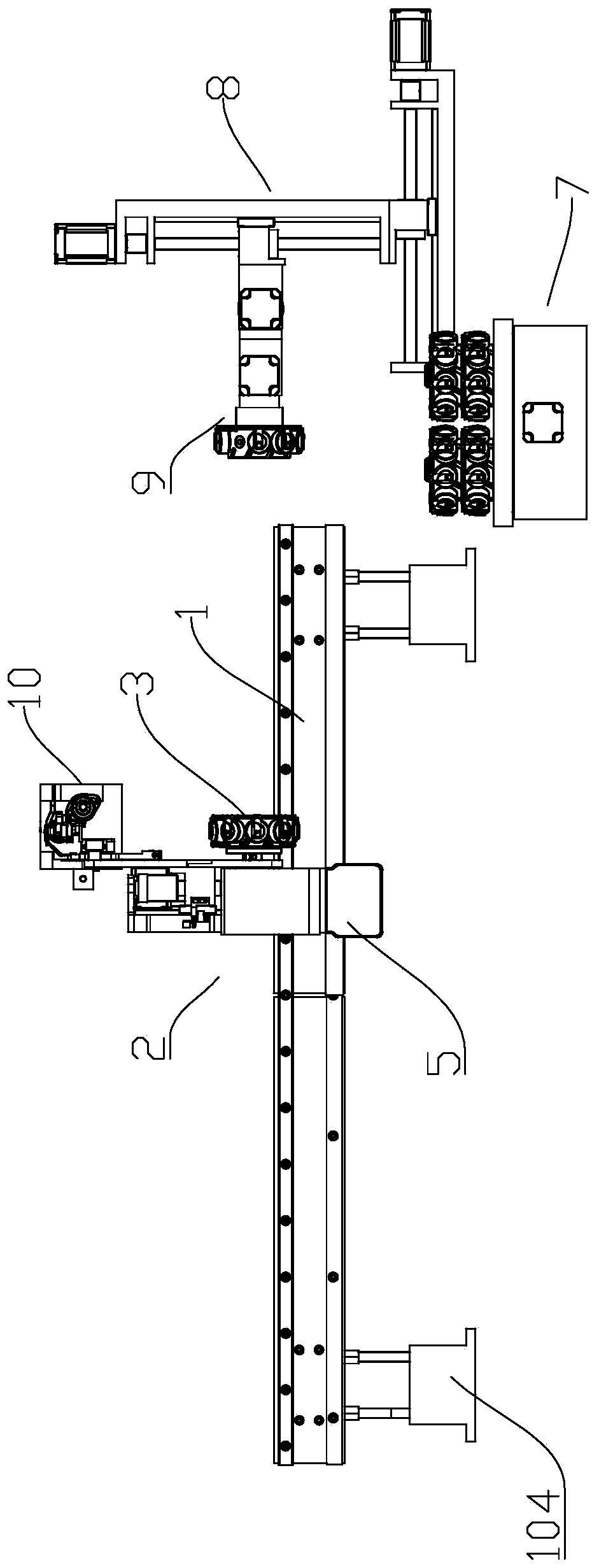

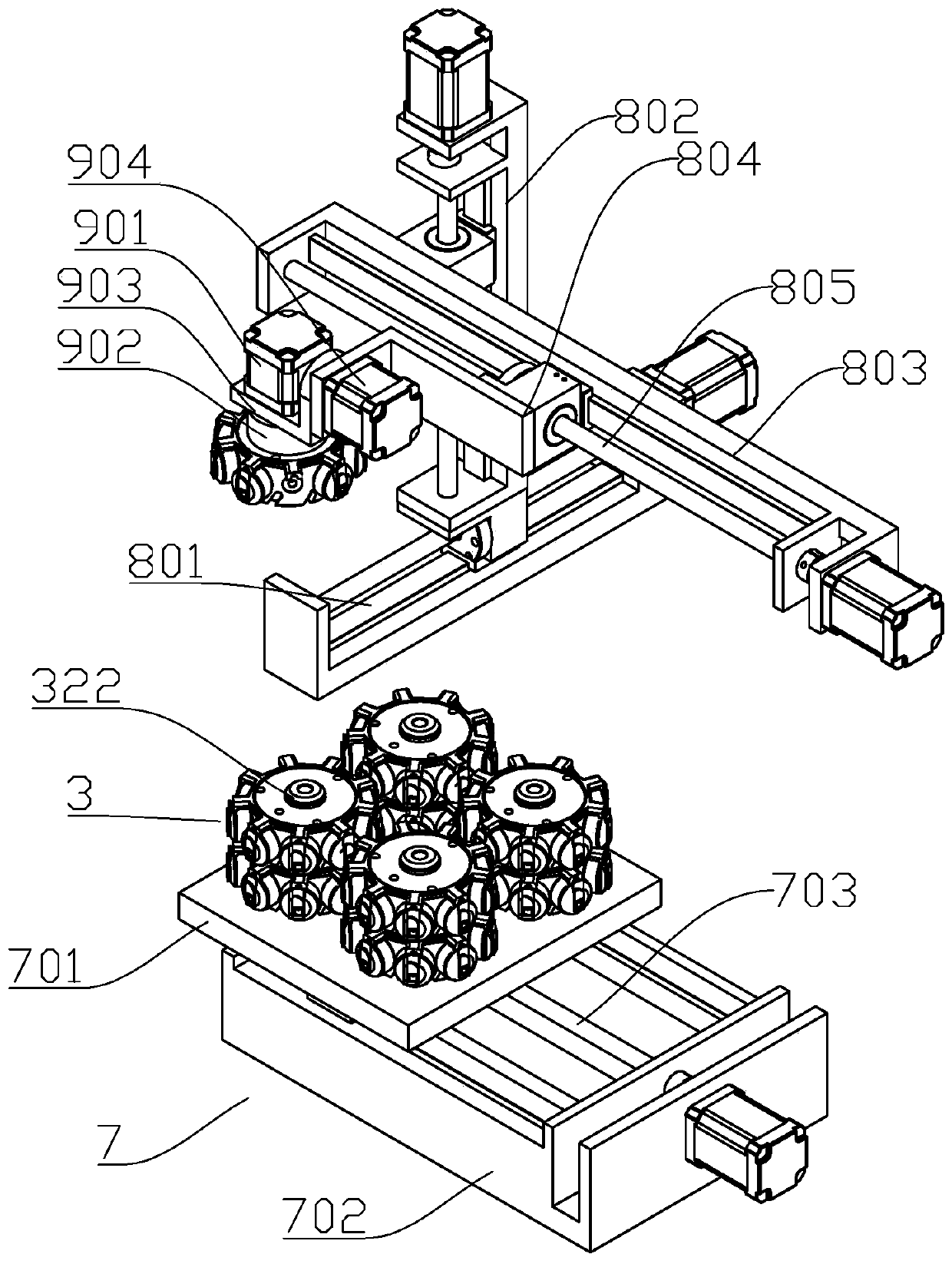

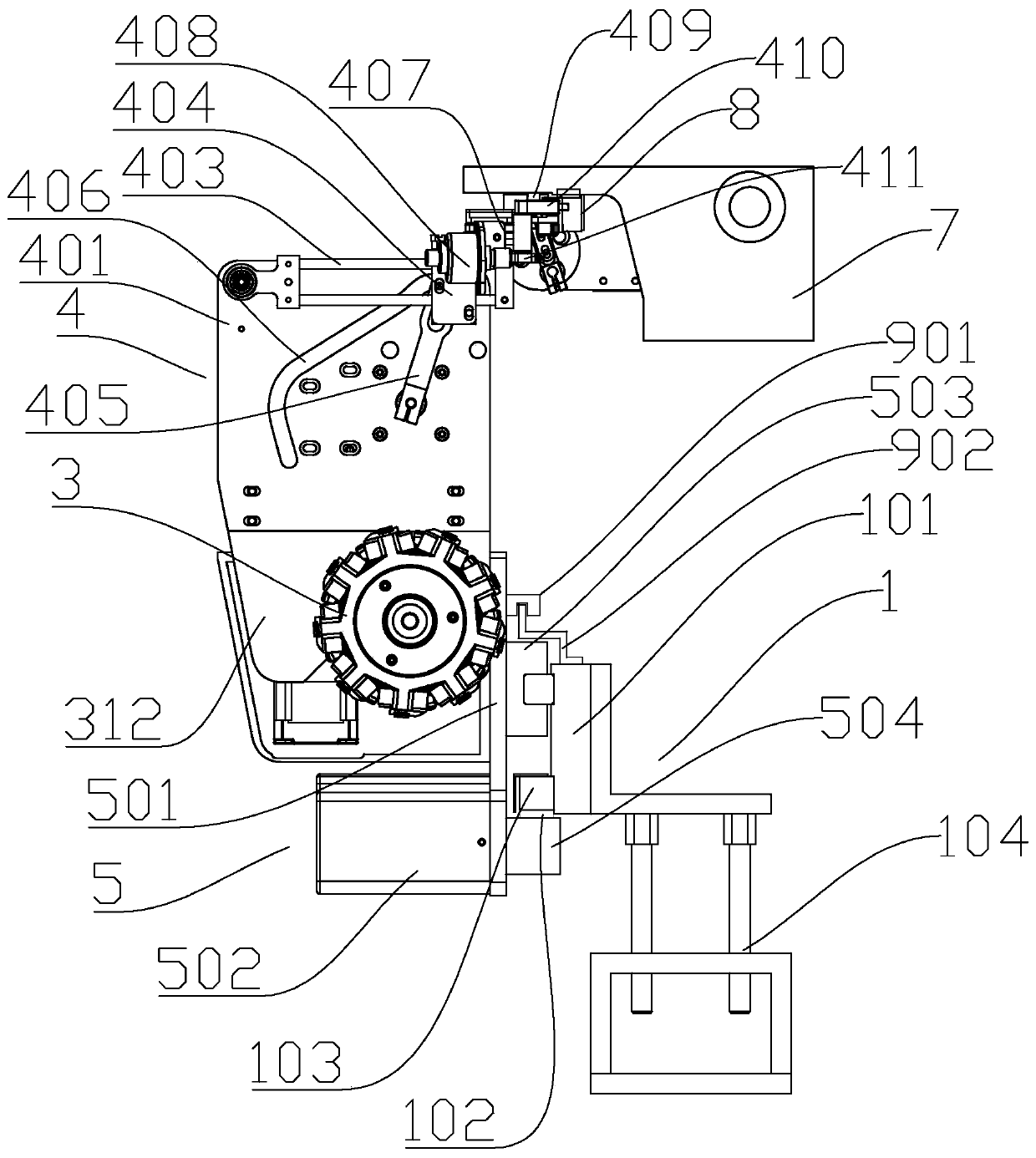

[0061] like figure 1 , image 3 , Figure 4 As shown, the application of the present invention provides a bobbin thread changing system for a fully automatic feeding multi-station embroidery machine, including a horizontal guide mechanism 1, a translation drive device 5, a bobbin case replacement device 2, a rotating storage tray 3 and automatic replacement of the storage tray device; the translation drive device 5 is slidably connected to the horizontal guide mechanism 1, and the bobbin case replacement device 2 is arranged on the translation drive device 5, and the bobbin case replacement device 2 is driven by the translation drive device 5 and can be used in multiple stations of the embroidery machine The rotating storage tray 3 is detachably connected to the bobbin case replacement device 2, and the rotating storage tray 3 is used to store a plurality of spare bobbin cases; the automatic storage tray replacement device is located at the horizontal guide mechanism 1 At on...

Embodiment 2

[0111] The biggest difference between this embodiment and the above-mentioned embodiment 1 is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com