Method for preparing special lactic acid bacteria synergized culture medium for pickled vegetables and application of special lactic acid bacteria synergized culture medium

A culture medium, lactic acid bacteria technology, applied in the field of microbial fermentation, can solve problems such as poor bacteriostatic properties, and achieve the effect of improving bacteriostatic activity and enhancing bacteriostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the lactic acid bacteria synergistic medium specially used for kimchi comprises the following steps: two kinds of lactic acid bacteria are cultured in MRS medium liquid and then expanded, the inoculum amount is 0.1%-10%, and after 6-24 hours of culture, they are mixed in proportion and then expanded. The culture medium is expanded for the second time, and the expansion seed solution is inoculated into the spice liquid according to the inoculum amount of 0.1-30%, and after pre-fermentation and cultivation for 6-48 hours, the special lactic acid bacteria synergistic medium for kimchi is obtained, and then proportionally and pre-treated The processed Jerusalem artichokes are mixed and fermented for 2-7 days.

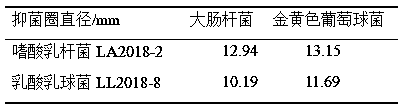

[0032] The two lactic acid bacteria are Lactobacillus acidophilus LA2018-2 and Lactococcus lactis LL2018-8, and the mixing ratio is 1:1.

[0033] The culture medium components for expansion are: 5-80 g / L of Jerusalem artichoke tubers, 1-60 g...

Embodiment 1

[0040] The application steps of the special lactic acid bacteria booster medium for pickles of the present application in processing pickles are:

[0041] Wash the fresh Jerusalem artichoke, dry it, slice it, and mix and ferment according to the ratio of spice liquid: Jerusalem artichoke = 3:1. The spice liquid contains 3% dried chili, 1% ginger, 0.1% star anise, 0.1% pepper, and 1.5% sugar. Inoculate 10% of mixed Lactobacillus acidophilus LA2018-2 and Lactococcus lactis LL2018-8 expansion medium for fermentation, ferment for 6 days, the total acid content (calculated as lactic acid) is 1.08g / L, and the amino acid nitrogen content in the fermentation broth is 0.93g / L. Among them, the nitrite content was the highest at 0.05 mg / kg at 1 day of fermentation, and no nitrite was detected at 6 days of fermentation. Escherichia coli, Staphylococcus aureus, Salmonella, and Shigella were tested for Jerusalem artichoke kimchi, and the results were not detected.

Embodiment 2

[0043] The application steps of the special lactic acid bacteria booster medium for pickles of the present application in processing pickles are:

[0044] Wash the fresh Jerusalem artichoke, dry it, slice it, and mix and ferment according to the ratio of spice liquid: Jerusalem artichoke = 3:1. The spice liquid contains 3% dried chili, 1% ginger, 0.1% star anise, 0.1% pepper, and 1.5% sugar. Inoculate 0.2% of mixed Lactobacillus acidophilus LA2018-2 and Lactococcus lactis LL2018-8 expansion medium for fermentation, ferment for 4 days, the total acid content (calculated as lactic acid) is 6.77g / L, and the amino acid nitrogen content in the fermentation broth is 0.76 g / L, among which, the nitrite content was the highest at 0.047 mg / kg when fermented for 1 day, and the nitrite content was not detected when fermented for 4 days. Pathogenic bacteria such as Escherichia coli were not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com