Reflective thermal-insulation coating used for external wall

A technology for reflective heat-insulating coatings and exterior walls, applied in the field of coatings, can solve the problems of easy agglomeration, poor dispersion of hollow glass microspheres, uneven reflection and heat insulation, etc., and achieve the effect of increasing dispersion performance, not easy to fall off, and uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

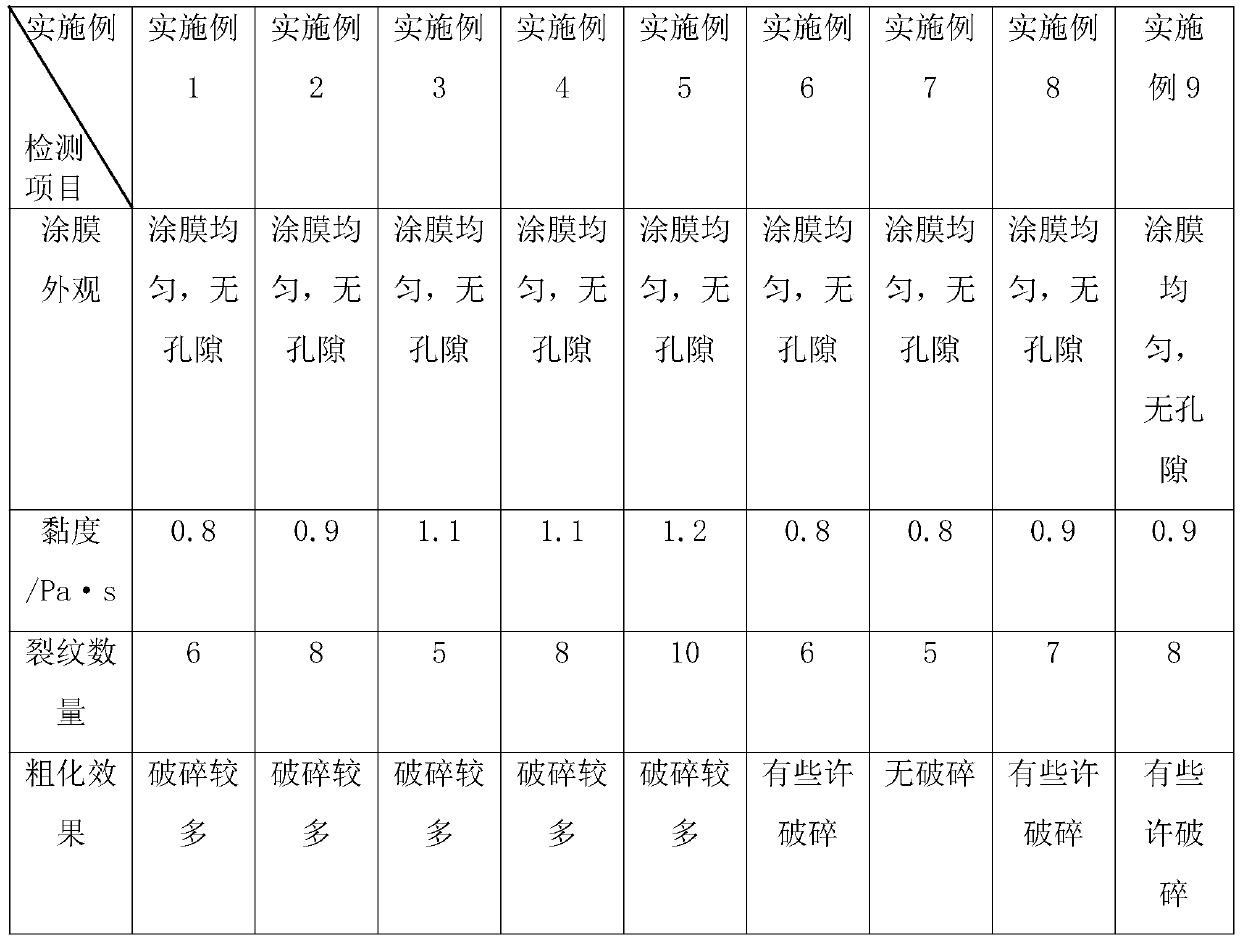

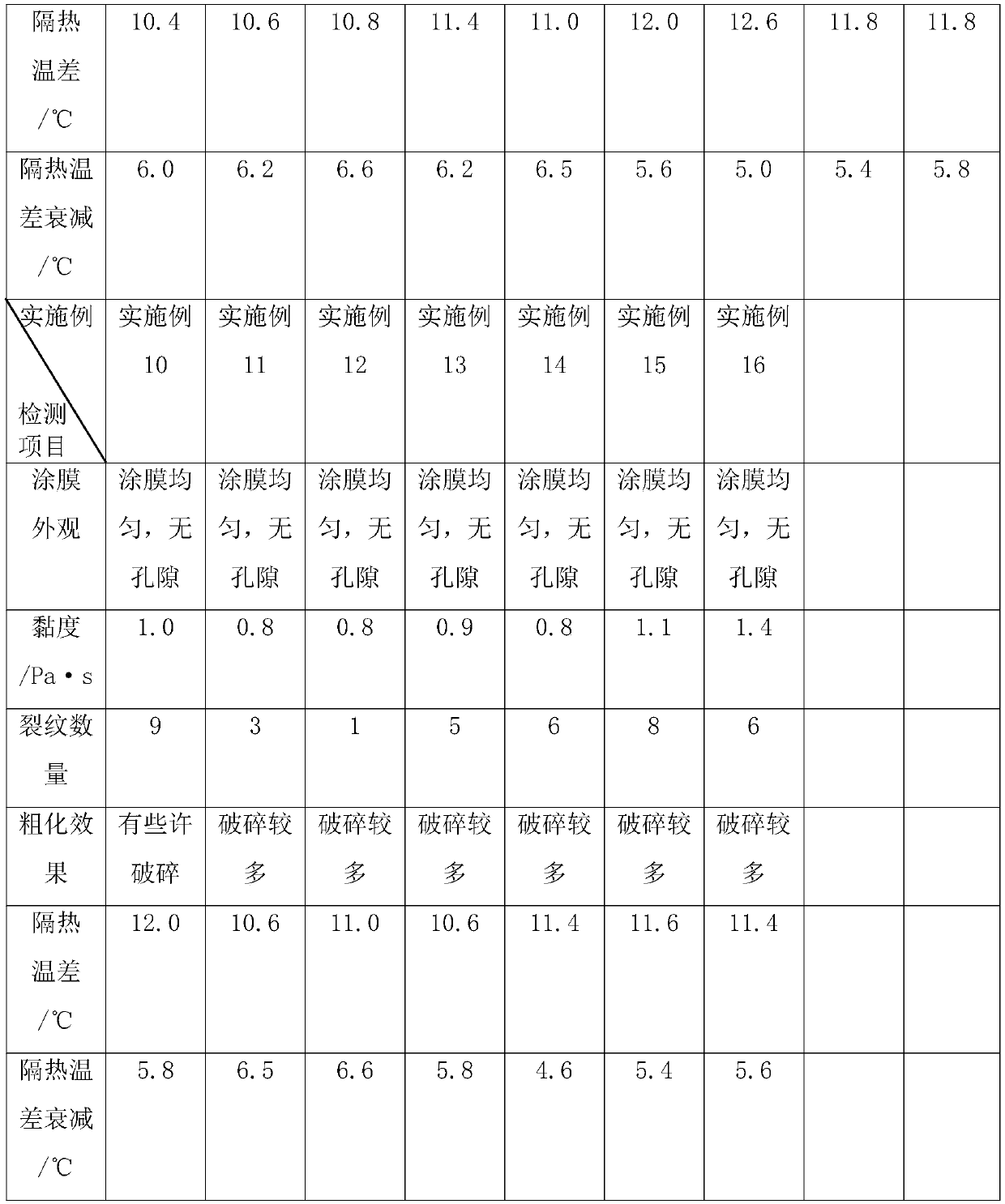

Examples

Embodiment 1

[0029] Example 1: A reflective and heat-insulating coating for exterior walls. The components and their corresponding parts by weight are shown in Table 1. Among them, the dispersant is sodium polyacrylate S298808 purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., the wollastonite powder is purchased from Hubei Fengjiashan Silicon Fiber Co., Ltd. WP325, and the styrene-acrylic emulsion is purchased from Anping, Anhui The styrene-acrylic emulsion AP-168 of Building Materials Co., Ltd., the defoamer is the paint defoamer Z-5189 purchased from Shanghai Yuewan New Material Co., Ltd., and the wetting agent is the wetting agent OT purchased from Shanghai Yudun Chemical Co., Ltd. -75, the film-forming aid is purchased from the film-forming aid JS-PPH of Shanghai Banggao Chemical Co., Ltd., the leveling agent is purchased from the polyurethane leveling agent HT-880 of Nantong Hantai Chemical Co., Ltd., and the pH regulator is ammonia.

[0030] The modified microbeads i...

Embodiment 2-5

[0042] Embodiment 2-5: a kind of reflective heat-insulating paint for exterior walls, the difference from embodiment 1 is that the parts by weight of its raw materials are as shown in table 1:

[0043] Each component and parts by weight thereof in table 1 embodiment 1-5

[0044]

Embodiment 6

[0045] Embodiment 6: A reflective heat-insulating coating for exterior walls, the difference from Example 1 is that in the preparation method of modified microbeads, the ceramic microbeads are roughened before adding ceramic microbeads in step 1, The specific coarsening processing method is:

[0046] Mix ceramic microbeads and sodium fluoride uniformly at a mass ratio of 1:0.5 to obtain a mixed powder, then add the mixed powder to a hydrochloric acid solution with a mass concentration of 5% for mechanical stirring, and acid etch to obtain a slurry, and after acid etching Solid-liquid separation of the slurry, drying the separated powder to obtain roughened ceramic beads;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com