Alginic acid-containing urea-based compound fertilizer and preparation method thereof

A technology of alginic acid and compound fertilizer, applied in phosphate fertilizer, superphosphate, fertilization device, etc., can solve the problems of less than 30% utilization rate of phosphate fertilizer, low utilization rate of compound fertilizer, soil salinization, etc., and achieve high utilization rate, Improve the content of functional organic matter and the effect of lasting fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

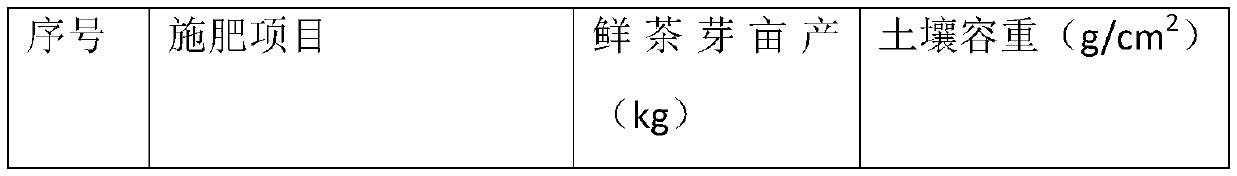

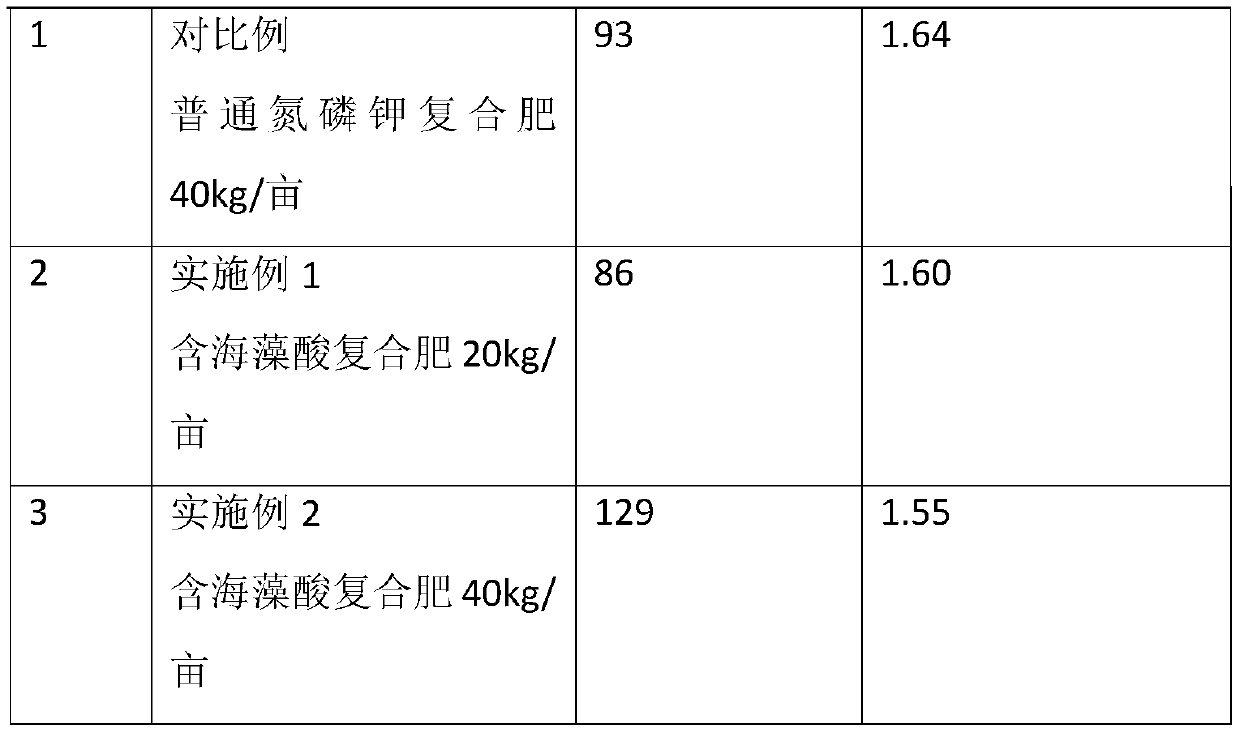

Examples

Embodiment 1

[0025] A urea-based compound fertilizer containing alginic acid, which is made of the following raw materials in parts by weight: 30 parts of urea, 15 parts of ammonium sulfate, 12 parts of monoammonium phosphate, 10 parts of potassium sulfate, 2 parts of alginic acid, boric acid 1 part, manganese sulfate 2 parts, superphosphate 7 parts, paraffin oil 1 part.

[0026] The preparation method of the urea-based compound fertilizer containing alginic acid comprises the following steps:

[0027] (1) Take each raw material according to the above ratio, and grind potassium sulfate, ammonium sulfate, manganese sulfate, monoammonium phosphate, alginic acid and boric acid into powder;

[0028] (2) Add calcium superphosphate into the mixing tank and preheat to 80°C for later use;

[0029] (3) Put urea into the melting tank, heat to 130°C, melt, then transfer into the mixing tank;

[0030] (4) Potassium sulfate, ammonium sulfate and manganese sulfate of the powder are dropped into the mi...

Embodiment 2

[0035] A urea-based compound fertilizer containing alginic acid, which is made of the following raw materials in parts by weight: 25 parts of urea, 15 parts of ammonium sulfate, 10 parts of monoammonium phosphate, 12 parts of potassium sulfate, 2 parts of alginic acid, boric acid 1 part, manganese sulfate 1 part, superphosphate 10 parts, paraffin oil 1 part.

[0036] The preparation method of the urea-based compound fertilizer containing alginic acid comprises the following steps:

[0037] (1) Take each raw material according to the above ratio, and grind potassium sulfate, ammonium sulfate, manganese sulfate, monoammonium phosphate, alginic acid and boric acid into powder;

[0038] (2) Add calcium superphosphate into the mixing tank and preheat to 80°C for later use;

[0039] (3) Put urea into the melting tank, heat to 130°C, melt, then transfer into the mixing tank;

[0040] (4) Potassium sulfate, ammonium sulfate and manganese sulfate of the powder are dropped into the mi...

Embodiment 3

[0045] A urea-based compound fertilizer containing alginic acid, which is made of the following raw materials in parts by weight: 45 parts of urea, 28 parts of ammonium sulfate, 13 parts of monoammonium phosphate, 10 parts of potassium sulfate, 1 part of alginic acid, boric acid 2 parts, manganese sulfate 2 parts, superphosphate 5 parts, paraffin oil 2 parts.

[0046] The preparation method of the urea-based compound fertilizer containing alginic acid comprises the following steps:

[0047] (1) Take each raw material according to the above ratio, and grind potassium sulfate, ammonium sulfate, manganese sulfate, monoammonium phosphate, alginic acid and boric acid into powder;

[0048] (2) Add calcium superphosphate into the mixing tank and preheat to 80°C for later use;

[0049] (3) Put urea into the melting tank, heat to 130°C, melt, then transfer into the mixing tank;

[0050] (4) Potassium sulfate, ammonium sulfate and manganese sulfate of the powder are dropped into the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com