Rope driven intelligent bin smoothing parallel robot

A rope-driven and robotic technology is applied in the field of rope-driven intelligent position-closing parallel robots, which can solve the problems of slow position-closing, harsh working environment, and large workload, and achieve reduced output torque, smooth position-closing action, and position-closing The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

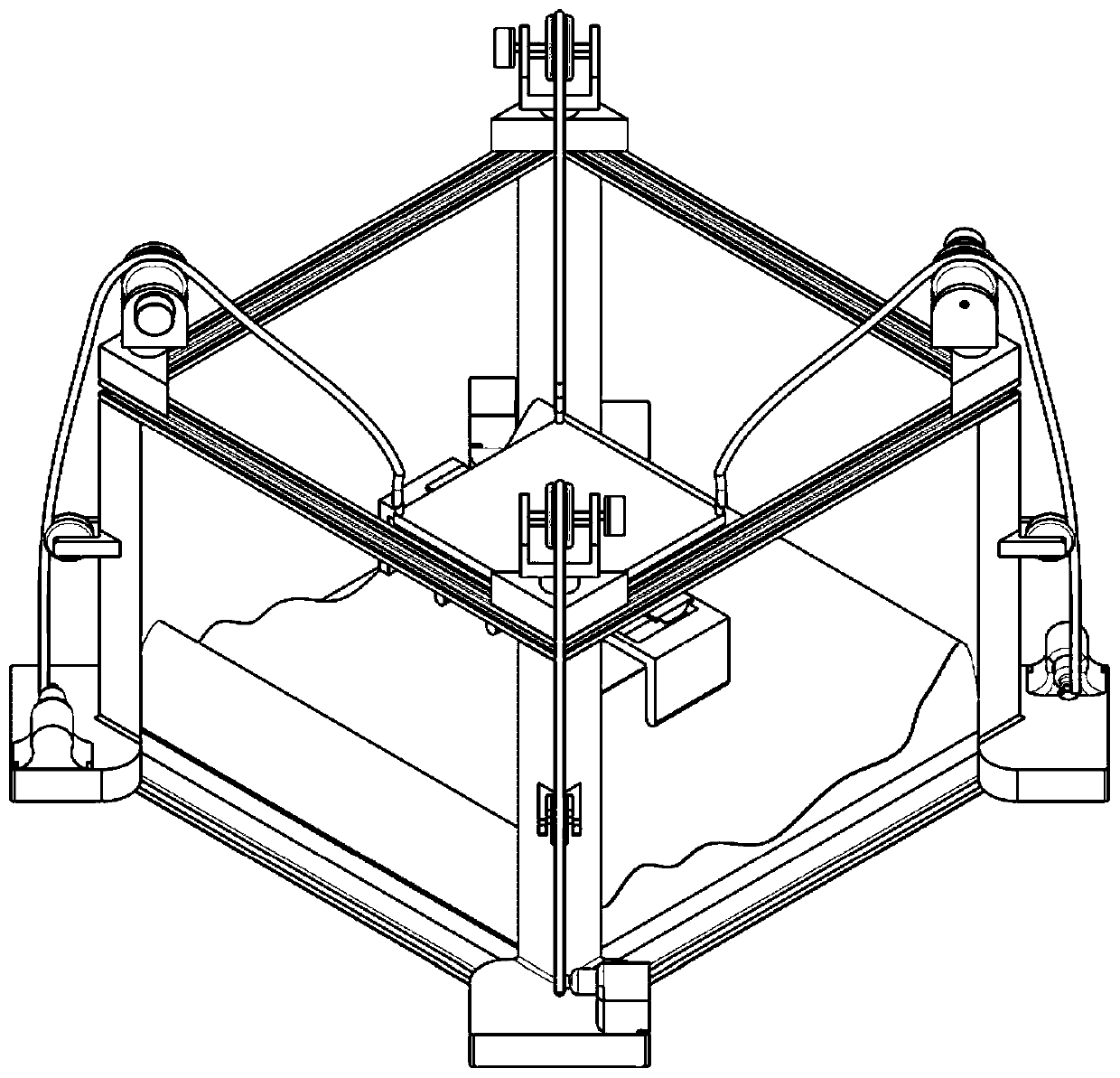

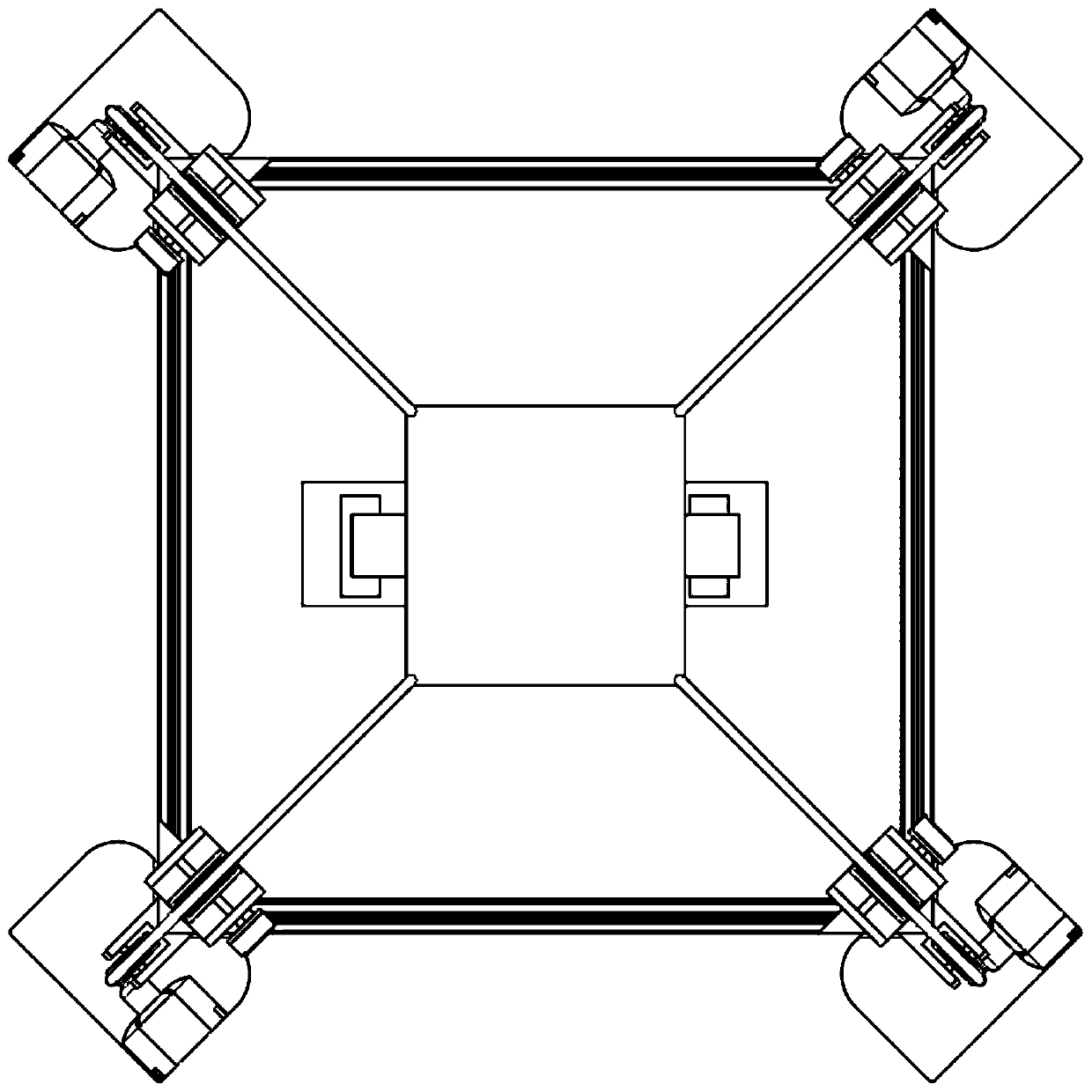

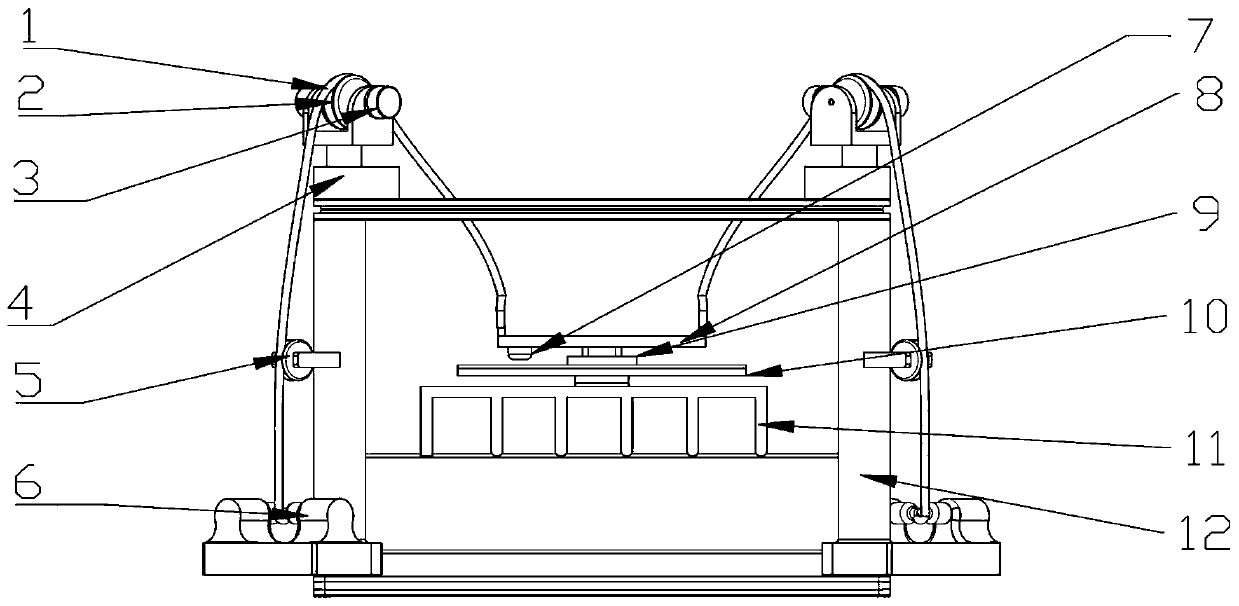

[0027] A rope-driven intelligent liquidation parallel robot, including a base, multiple sets of support columns 12, hoist 6, rope 1, auxiliary wheels 5, fixed pulley assembly, central workbench 8, central turntable 9, direct drive linear motor 10, Tool 11, laser scanner 7, upper computer,

[0028] The multi-set fixed pulley assembly includes a bracket, a rotating shaft, a fixed pulley 2, a code disc 3, and a turntable 4. The fixed pulley 2 is fixed on the rotating shaft, and the rotating shaft is installed on the bracket. The code disc 3 is arranged at one end of the rotating shaft, and the bracket is arranged on the turntable 4. The bracket can rotate around the Z axis on the turntable 4;

[0029] The liquida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com