Strap type belt cleaner

A cleaner and belt technology, applied in the field of belt conveyor surface cleaning, can solve the problems of tearing the rubber coating of the drum, poor cleaning effect, affecting the life of the drum, etc., and achieves excellent wear resistance, overall lightness, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

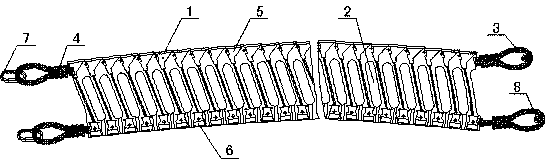

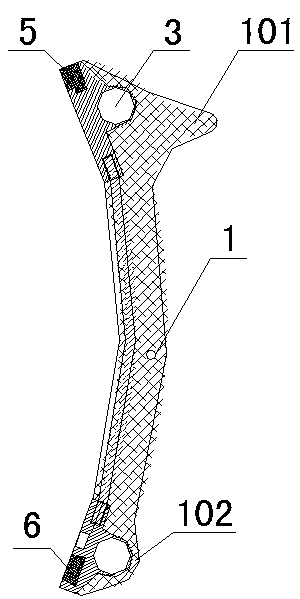

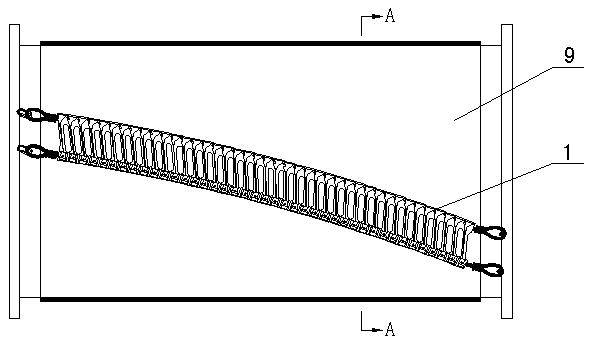

[0021] Now in conjunction with accompanying drawing and embodiment, the present invention is described in further detail: as Figure 1~2 As shown, a strap-type belt cleaner of the present invention includes a cleaner body 1 with a rectangular strip shape, the long side is in the shape of an arc, the upper part is provided with a bird's beak guide block 101, and the lower part is provided with an arc-shaped convex The guide block 102 has an arc-shaped bottom surface, and the arc matches the diameter of the outer circle of the attached drum, so that it fits well on the belt surface of the drum; the cleaner body 1 is provided with equally spaced opening grooves 2, so that The opening slots 2 are distributed in a regular inclination; the two ends of the cleaner body 1 are provided with steel wire loops 3, and there are four steel wire loops 3, which are fixed to the two ends of the cleaner body 1 by fastening devices 4; One end of the wire rope ring is connected to the chain 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com