Material jamming device

A technology of materials and driving devices, which is applied in the field of balers, can solve the problem that the packing effect of compressed bales cannot be optimal, and achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

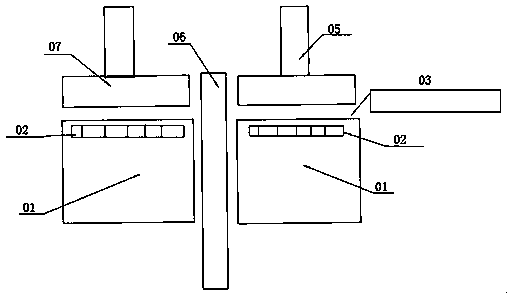

[0026] like Figure 1-9 As shown, it is a material blocking device of the present invention, which includes a driving device, a long shaft 13 , a blocking mechanism set in the middle of the long shaft 13 and a linkage mechanism set at the end of the long shaft 13 .

[0027] The jamming mechanism of the present invention includes a position-limiting cotton claw plate 5 , a long shaft sleeve 6 , a fulcrum 22 , a fulcrum sleeve 23 , a claw plate 24 , a shock-absorbing bracket 19 and a shock-absorbing pad 14 . The central part of the long axis 13 of the present invention is provided with a plurality of claw plates 24 at equal intervals, and a long shaft sleeve 6 is arranged between two adjacent claw plates 24; the long shaft sleeve 6 is sleeved on the long shaft 13, for The axial direction of the claw plate 24 installed on the major axis is limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com