Manufacturing process of composite floor with irregular wire-shaped wood veneer

A compound flooring and manufacturing technology, which is applied in the direction of manufacturing tools, wood processing appliances, metal processing equipment, etc., can solve the problem of single surface treatment effect of the floor, and achieve a strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

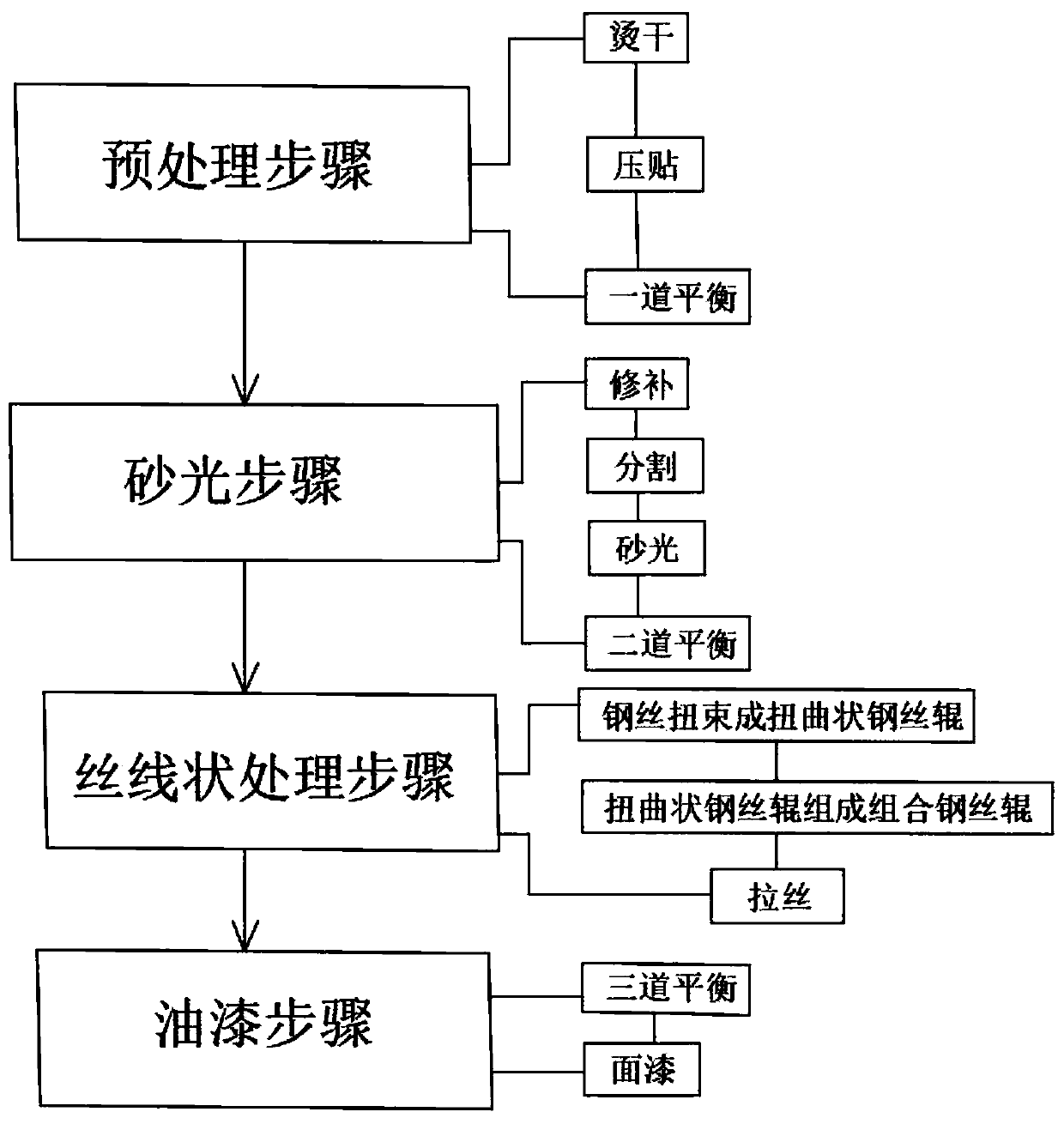

[0023] Example one, such as figure 1 As shown, a manufacturing process of irregular silk-like wood veneer composite flooring includes the following steps:

[0024] In the pretreatment step, after the panels are sorted according to the appropriate grade and size, they are scalded and dried to the proper moisture, and the dried panels and the substrates after the glue are pressed by a hot press and sent to the balance room for a balance To complete the production of the primary floor;

[0025] In the sanding step, the surface of the primary floor is repaired in a semi-collapsed manner, and then the primary floor is divided by a cutting machine, and then the divided primary floor is sanded by a sander, and finally Send it to the balance room for second balance to complete the production of sanding floor;

[0026] The wire-like processing step is to twist multiple steel wires into a group of twisted steel wire rollers, combine a plurality of the twisted steel wire rollers with differen...

Embodiment 2

[0034] Example two, such as figure 1 As shown, a manufacturing process of irregular silk-like wood veneer composite flooring includes the following steps:

[0035] In the pretreatment step, after the panels are sorted according to the appropriate grade and size, they are scalded and dried to the proper moisture, and the dried panels and the substrates after the glue are pressed by a hot press and sent to the balance room for a balance To complete the production of the primary floor;

[0036] In the sanding step, the surface of the primary floor is repaired in a semi-collapsed manner, and then the primary floor is divided by a cutting machine, and then the divided primary floor is sanded by a sander, and finally Send it to the balance room for second balance to complete the production of sanding floor;

[0037] The wire-like processing step is to twist multiple steel wires into a group of twisted steel wire rollers, combine a plurality of the twisted steel wire rollers with differen...

Embodiment 3

[0046] Example three, such as figure 1 As shown, a manufacturing process of irregular silk-like wood veneer composite flooring includes the following steps:

[0047] In the pretreatment step, after the panels are sorted according to the appropriate grade and size, they are scalded and dried to the proper moisture, and the dried panels and the substrates after the glue are pressed by a hot press and sent to the balance room for a balance To complete the production of the primary floor;

[0048] In the sanding step, the surface of the primary floor is repaired in a semi-collapsed manner, and then the primary floor is divided by a cutting machine, and then the divided primary floor is sanded by a sander, and finally Send it to the balance room for second balance to complete the production of sanding floor;

[0049] The wire-like processing step is to twist multiple steel wires into a group of twisted steel wire rollers, combine a plurality of the twisted steel wire rollers with differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com